Air Suspension Centrifugal Blowers with Multiple Power Options (7.5KW - 600KW)

-

Air Dynamic Pressure Suspension Bearing Technology

- Our blowers feature air dynamic pressure suspension bearings, including radial and thrust bearings. Before startup, there is physical contact between the rotating shaft and the bearings. During startup, relative motion generates a hydrodynamic field, and the hydrodynamic force in the radial bearings creates a levitation force that keeps the rotating shaft suspended, enabling smooth rotation. Unlike traditional ball bearings, there is no physical contact during operation, eliminating the need for lubricating oil, resulting in extremely low energy loss and high efficiency. The maintenance - free air bearings enhance the blower's service life, which exceeds 20 years, and reduce the frequency of daily maintenance.

-

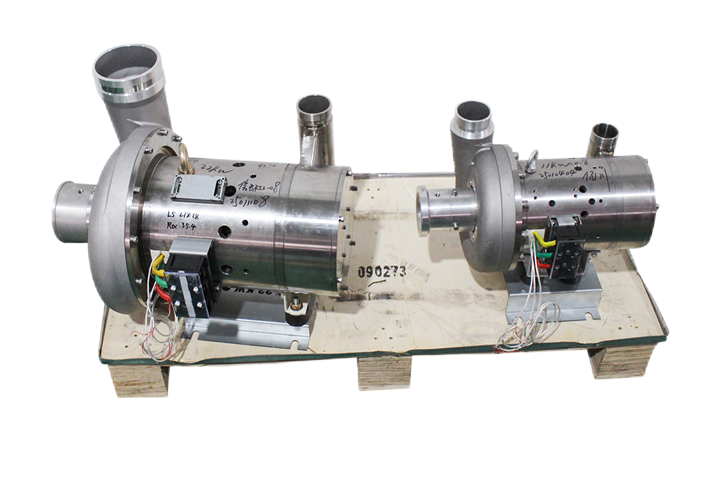

2. High - speed Permanent Magnet Synchronous Motor

- Developed jointly with Shandong University of Technology, our latest - generation high - efficiency permanent magnet synchronous motor achieves an efficiency of 98% (first - class energy efficiency). It maintains a high power factor even under variable external loads. With a voltage of 380V, a high - frequency controller, insulation class H, and a continuous working system, the motor's core component, the rotor, is made of samarium - cobalt permanent magnet material, known for its high temperature resistance and high magnetic strength. With an IP56 protection rating, it is suitable for dusty, corrosive, and humid environments. The one - piece structure of the rotor and impeller, with dynamic balance controlled within 5mg (G1 level), ensures no resonance during normal operation, and the main unit vibration value does not exceed 1mm/s, complying with JB/T8689 vibration detection and limits. The motor and control parts are in a separate closed - chamber structure for easy heat dissipation and maintenance. The stainless - steel 304 housing is suitable for multi - condition and long - term stable operation, with a maximum speed of up to 100000RPM, smaller size, lighter weight, and higher power density. The starting current is only 4.5% of the rated current, eliminating the need for additional soft - starters, and the direct connection between the impeller and the rotor shaft eliminates mechanical transmission losses.

-

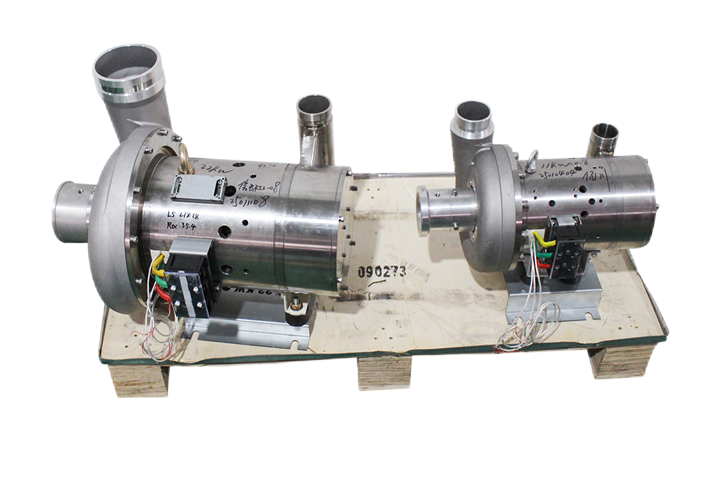

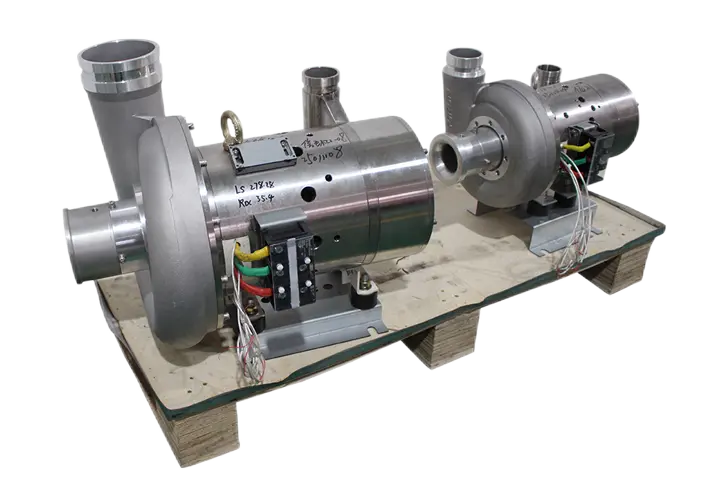

Three - Dimensional Flow Impeller

- The impeller of our air suspension centrifugal blowers is a three - dimensional flow impeller made of AL7075 aviation forged aluminum with a backward - curved integral design. It is a semi - open impeller directly connected to the motor shaft. Manufactured as a whole from high - strength aluminum alloy, it undergoes static and dynamic balance tests according to ISO1940 standards. Milled by a five - axis machining center and surface - treated with chromic acid anodization for corrosion protection, it is directly fixed on the output shaft of the air - suspended high - speed permanent magnet motor and is easy to disassemble and assemble. The design ensures sufficient strength and stiffness, with a safety margin of more than 1.2 times under the maximum speed operating conditions. The efficiency of the centrifugal impeller within the range of ±20% of the rated volume flow is not less than 80%. The precision - cast aluminum volute has a horizontal or vertical suction side and a vertical or horizontal discharge side, depending on the model. The three - dimensional flow impeller design features wear - resistance and anti - locking, with independent patents.

-

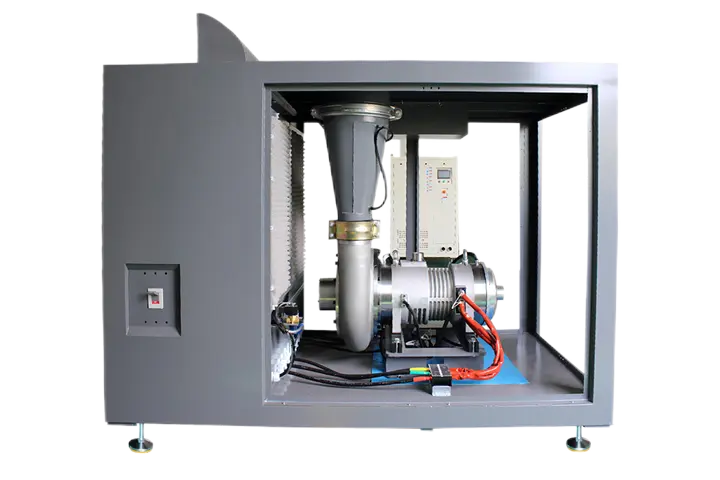

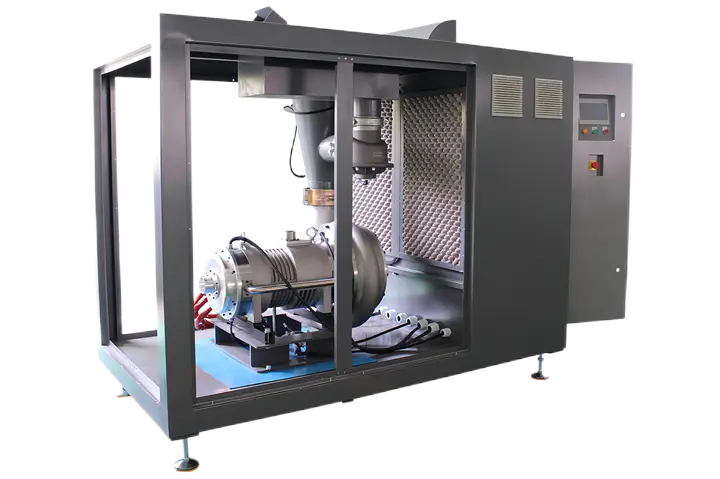

High - efficiency Variable Frequency Control Technology

- Our air suspension centrifugal blowers adopt high - speed dedicated variable frequency technology with sensorless vector closed - loop control, improving operation efficiency and optimizing the fan system performance. The motor can be started 100% by the frequency converter, with precise operation and good parameter adaptability. The control efficiency is over 96%, with a rapid response to load changes. The built - in DC reactor effectively suppresses power harmonics. With comprehensive protection functions, it ensures high stability and reliability. The motor speed can be controlled by the frequency converter to adjust the required air flow and pressure for different working conditions. The built - in kinetic energy back - up capacitor allows the motor to generate electricity using its kinetic energy in case of sudden power failure, ensuring safe shutdown.

-

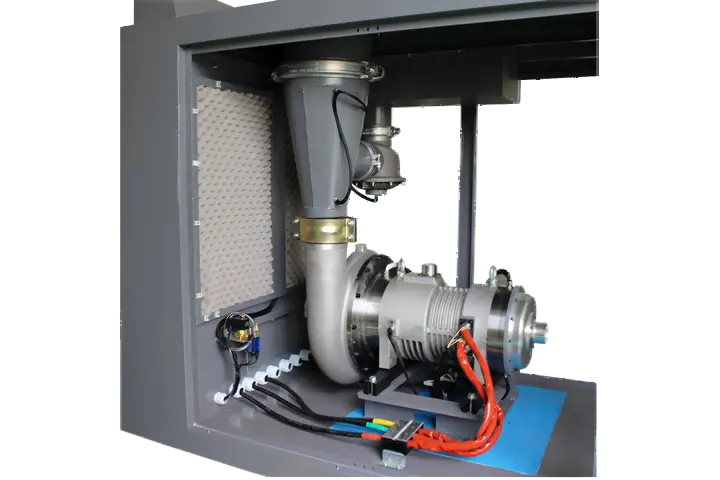

Diverse Cooling Systems

- Our independently developed diverse cooling systems ensure that the blower system can operate economically and reliably even in hot summer, reducing maintenance workload and failure rate. The water - cooling system features a unique internal - circulation water - cooling system for optimal cooling, while the air - cooling system is a perfect self - suction cooling system that does not require additional equipment and can cool the motor and frequency converter using the inhaled air. The heat generated inside the equipment can be prevented from being discharged outside the chassis to maintain a suitable working and operating environment.

-

Vibration - free and Low - noise Operation

- When operating alone, the noise of the main unit of our air suspension centrifugal blowers is less than 80dB(A) according to the GB/T 2888 - 2008 "Noise Measurement Methods for Fans and Roots Blowers" (excluding the noise from air ducts, valves, elbows, etc.). The air suspension bearings and direct - connection technology eliminate vibration, and the blower does not require additional sound - proofing devices, with a noise level of only 75 - 80dB.

-

Oil - free and Maintenance - free

- With 100% oil - free non - contact bearings self - lubricated by air, there is no need for a lubricating oil system, reducing friction. Without the need for traditional gearboxes, couplings, and oil - type bearings, the direct connection between the impeller and the motor ensures maintenance - free operation, greatly reducing the user's maintenance costs and improving the stability of the air - supply system.

-

Convenient Operation Control

- The blower is controlled by PLC and a high - speed frequency converter. The parameters of the blower, such as air pressure and air volume, can be easily adjusted through a touch screen. It can also be controlled via the Internet of Things, allowing parameter adjustment and real - time monitoring through a computer or mobile APP for remote operation. The programmable logic controller uses a Siemens S7 - 200smart central processing unit and temperature acquisition.