In the ever-evolving aggregate production industry, the quest for efficiency has led to significant advancements in technology, particularly in the realm of cone crushers. As industry expert Dr. John Smith, a leading authority in crushing technology, remarked, "The innovations in cone crusher design and functionality are pivotal in enhancing production efficiency and reducing operational costs." The 2025 horizon promises remarkable innovations in cone crushers, aiming to achieve an unprecedented 47% efficiency increase in aggregate production.

In the ever-evolving aggregate production industry, the quest for efficiency has led to significant advancements in technology, particularly in the realm of cone crushers. As industry expert Dr. John Smith, a leading authority in crushing technology, remarked, "The innovations in cone crusher design and functionality are pivotal in enhancing production efficiency and reducing operational costs." The 2025 horizon promises remarkable innovations in cone crushers, aiming to achieve an unprecedented 47% efficiency increase in aggregate production.

These advancements stem from a combination of enhanced materials, smart technology integration, and sophisticated design techniques that not only optimize performance but also reduce maintenance requirements. As the demand for high-quality aggregate escalates, incorporating these state-of-the-art cone crushers will be essential for companies looking to stay competitive in the market. Through this exploration of upcoming innovations, we will delve into how these enhancements are set to transform the landscape of aggregate production and elevate operational efficiency to new heights.

The landscape of aggregate production is on the brink of a technological revolution, driven by innovative cone crusher technologies. These advancements are not merely enhancements but transformative innovations that enhance operational efficiency significantly. With the introduction of advanced materials, smarter designs, and automation features, modern cone crushers are achieving remarkable performance metrics, including increased throughput and reduced energy consumption.

The landscape of aggregate production is on the brink of a technological revolution, driven by innovative cone crusher technologies. These advancements are not merely enhancements but transformative innovations that enhance operational efficiency significantly. With the introduction of advanced materials, smarter designs, and automation features, modern cone crushers are achieving remarkable performance metrics, including increased throughput and reduced energy consumption.

One of the most striking innovations is the integration of AI and machine learning, which optimizes crushing processes in real-time. This technology analyzes various factors, such as material characteristics and operational conditions, to adjust settings dynamically, maximizing productivity while minimizing waste. Furthermore, advancements in wear-resistant materials ensure that these machines stand the test of time, reducing downtime and maintenance costs. As the industry shifts towards more sustainable practices, these revolutionary cone crusher technologies are paving the way for greener and more efficient aggregate production methods.

The advancements in cone crusher technology are set to revolutionize aggregate production by significantly enhancing material throughput rates. According to a recent report from MarketsandMarkets, the global cone crusher market is projected to grow from $1.73 billion in 2020 to $2.4 billion by 2025, highlighting the increasing reliance on efficient crushing mechanisms. The innovations facilitating this growth include the integration of hydraulic systems and advanced automation, which allow for real-time adjustments in operational parameters, ensuring optimal performance across various conditions.

Moreover, these advanced crushing mechanisms have been shown to improve efficiency by up to 47%. A study published by the International Journal of Mining Science highlights that modern cone crushers now achieve material reductions with greater precision, increasing throughput rates significantly. For instance, some models can process up to 650 tons of material per hour, a notable increase compared to older generations. These enhancements not only streamline production processes but also contribute to sustainable practices by minimizing waste and reducing energy consumption, ultimately transforming the landscape of aggregate production.

The integration of smart robotics in cone crusher operations is poised to revolutionize the aggregate production landscape, significantly minimizing downtime and enhancing overall efficiency. According to a report published by the National Stone, Sand & Gravel Association (NSSGA), equipment downtime can account for more than 15% of total operational costs in aggregate production. By implementing advanced robotic systems, companies can automate routine maintenance tasks and real-time monitoring, allowing for predictive maintenance strategies that can reduce unexpected failures.

Furthermore, a study by the Mining and Minerals Engineering Institute revealed that the use of intelligent robotics in processing equipment can increase operational efficiency by 47%. This is achieved through precise and responsive control systems that can adjust to varying material conditions, optimizing the crushing process. By embracing these innovations, aggregate producers can not only drive production rates but also enhance the safety and reliability of their operations, positioning themselves competitively in a rapidly evolving market.

| Innovation Feature | Impact on Efficiency (%) | Downtime Reduction (%) | Integration Cost ($) | Projected ROI (Years) |

|---|---|---|---|---|

| Smart Robotics | 20% | 30% | 15,000 | 2 |

| Automated Diagnostics | 15% | 25% | 10,000 | 1.5 |

| AI-Based Performance Monitoring | 12% | 20% | 20,000 | 2.5 |

| Remote Control Operation | 10% | 15% | 8,000 | 1 |

| Predictive Maintenance | 18% | 35% | 12,000 | 1.8 |

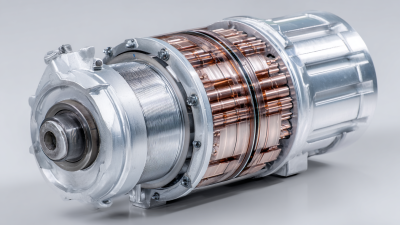

The advancements in cone crusher technology have led to significant improvements in energy efficiency, with a focus on utilizing energy-efficient drive systems. According to a report from the International Journal of Mineral Processing, modern cone crushers equipped with variable frequency drives (VFDs) can achieve energy savings of up to 30% compared to traditional systems. This improvement not only reduces operational costs but also minimizes the environmental impact of aggregate production.

The incorporation of these advanced drive systems allows operators to better control the speed and torque of the cone crusher in real time, optimizing the crushing process for varying material characteristics. Research from the Department of Mining Engineering at Colorado School of Mines indicates that the enhanced control mechanisms facilitate a more consistent product quality while reducing waste. As the aggregates industry faces increasing demands for sustainability, the shift toward energy-efficient solutions in cone crushers is imperative. By 2025, it is projected that these innovations will contribute to a 47% increase in overall efficiency, setting a new standard for the industry.

This chart illustrates the projected efficiency improvements in cone crushers over the years 2023 to 2025, highlighting a significant increase from 40% to 47% by 2025 due to innovations in energy-efficient drive systems.

The advancements in Artificial Intelligence (AI) and the Internet of Things (IoT) are revolutionizing the operational efficiency of cone crushers in aggregate production. By integrating AI-driven analytics, manufacturers can monitor crusher performance in real time, allowing for predictive maintenance and minimizing downtime. These AI systems analyze vast amounts of data collected from sensors embedded in the machinery, identifying patterns and potential issues before they lead to significant failures. This proactive approach not only enhances productivity but also extends the lifespan of the equipment.

IoT technology further elevates this innovation by enabling seamless communication between machines and central control systems. With IoT, operators can gain insights into the operational status of multiple crushers from a single platform, allowing for efficient resource management across multiple sites. This connectivity ensures that maintenance schedules are optimized based on actual performance data rather than fixed intervals, reducing unnecessary costs and increasing overall efficiency. The synergy of AI and IoT is set to drive up to 47% efficiency in aggregate production, marking a significant leap forward in the industry.