The Pm Synchronous Motor stands out in the realm of electric machinery. Renowned for high efficiency, it operates with precision and reliability. Industries adopt these motors widely due to their superior performance and versatility.

These motors power various applications, from electric vehicles to industrial drives. Their unique features allow them to deliver consistent torque and speed control. However, some challenges also exist, such as the initial cost and the need for skilled maintenance.

Understanding the 2026 Best Pm Synchronous Motor features reveals their potential. Innovations continue to emerge, enhancing motor design and functionality. The future may offer solutions to overcome current limitations while expanding applications across various sectors.

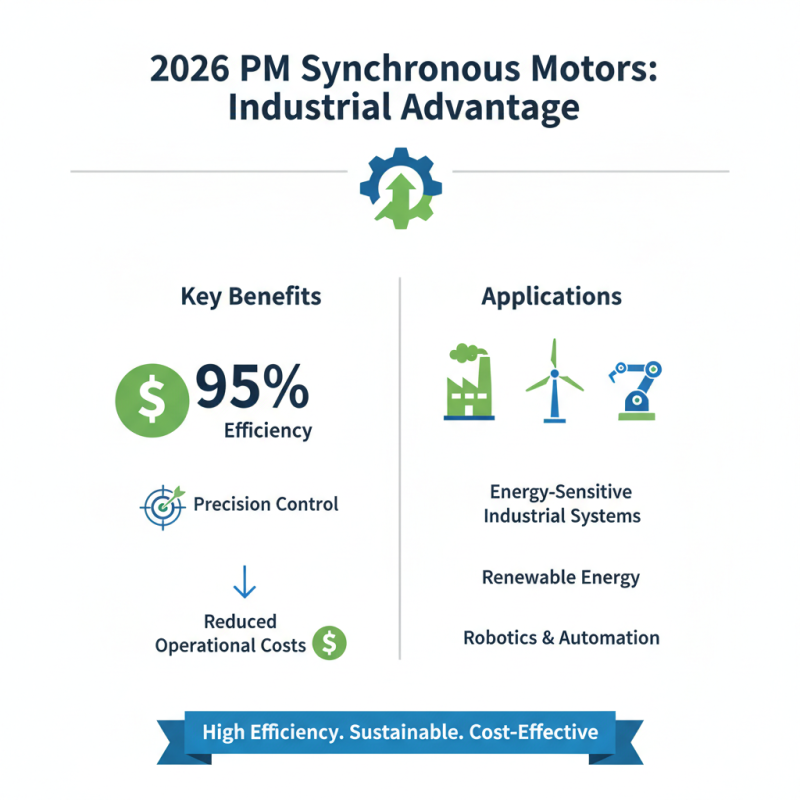

The 2026 PM synchronous motors are gaining traction in industrial applications. These motors are known for their high efficiency and precision. According to recent market reports, the efficiency of these motors can exceed 95%. This makes them ideal for energy-sensitive applications, significantly reducing operational costs.

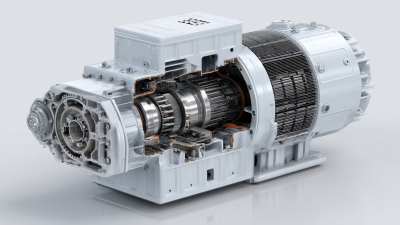

The compact design of these motors allows for easier integration into various machinery. They are often used in food processing, packaging, and automation systems. A survey indicated that approximately 30% of industrial users prefer PM synchronous motors for their reliability and performance. However, costs can be a concern. The initial investment may deter some companies, especially smaller businesses.

Maintenance is another challenge. While these motors require less maintenance compared to traditional motors, when issues occur, repairs can be complex. Additionally, compatibility with existing systems may not always be guaranteed. Companies often face the dilemma of upgrading their machinery or sticking with outdated motors. Despite these concerns, the advantages of PM synchronous motors are clear. Their growing adoption in industry cannot be overlooked.

Permanent Magnet (PM) synchronous motors are transforming various industries. They offer high efficiency, a key performance metric. The efficiency often exceeds 90%. This means less energy waste and reduced operational costs for businesses. However, achieving such efficiency relies heavily on design and application.

Torque is another critical factor. PM synchronous motors can deliver high torque at low speeds. This feature is beneficial in applications like robotics and electric vehicles. But, achieving optimal torque requires careful matching of motor specifications to the intended application. Sometimes, this can lead to oversizing or undersizing issues.

Designers often face challenges in balancing efficiency and torque. Performance can vary based on materials and control systems used. Some may prioritize cost over efficiency. This could lead to future retrofitting needs. Finding the right compromise is essential for success in real-world applications. Each choice comes with its trade-offs. Understanding these can significantly influence the motor's overall performance in various scenarios.

| Feature | Value |

|---|---|

| Efficiency | 90-95% |

| Torque Density | 2.0-2.5 Nm/kg |

| Speed Range | 0-3000 RPM |

| Power Factor | 0.95-0.99 |

| Cooling Type | Air or Liquid Cooled |

| Applications | Electric Vehicles, Robotics, Industrial Drives |

| Cost | $$$ (Moderate to High) |

Permanent Magnet (PM) Synchronous Motors have gained traction in various sectors due to their efficient performance. They are favored for their high power density and robust torque characteristics. A report from the International Energy Agency indicates that these motors can operate at over 95% efficiency, which is considerably higher than the typical 85% for induction motors. This efficiency translates into significant energy savings in applications ranging from industrial drives to electric vehicles.

When compared to other motor types, PM Synchronous Motors exhibit superior responsiveness. Their torque remains consistent across a wide speed range, making them ideal for precise control applications. However, they can be costlier to produce due to the use of rare earth materials. Despite this drawback, their longevity and reduced maintenance needs often justify the initial investment. It's crucial to weigh these factors when choosing a motor type for your projects, as not all applications will benefit equally from the strengths of PM motors.

Despite their advantages, PM motors are not without flaws. The sensitivity to temperature variations can impact performance. Additionally, sourcing rare earth materials poses ethical and environmental dilemmas. These considerations are essential for engineers and project managers. They highlight the need for a balanced approach in selecting the right motor technology for specific applications.

In 2026, permanent magnet (PM) synchronous motors are set to undergo significant advancements. New materials will enhance motor efficiency. Innovations in design will make these motors lighter and smaller. This shift will cater to tight spaces in modern applications.

Trends also show increased integration with digital technologies. Smart diagnostics will offer real-time insights. Users may find maintenance easier with predictive analytics. Efficiency improvements can lower operating costs. Yet, this complexity raises concerns about reliability. As technology evolves, managing these systems effectively will become crucial.

**Tips:** Focus on understanding energy needs. Evaluate your specific applications carefully. Feedback from users can guide improvements too. Adopting new technology takes time. Remain patient as these systems develop further.

Permanent Magnet (PM) Synchronous Motors are making significant strides in renewable energy systems. These motors are highly efficient, which is crucial in sectors focused on sustainability. For instance, a recent report indicated that PM motors can achieve efficiencies up to 95%. This efficiency directly translates to reduced energy consumption and lower operating costs.

In wind energy applications, PM Synchronous Motors play a vital role in converting wind kinetic energy into electrical energy. Wind turbines equipped with these motors can operate effectively in a wide range of conditions, maximizing energy capture. A study by the National Renewable Energy Laboratory shows that integrating PM motors can enhance wind turbine efficiency by nearly 10%. This improvement can help address energy demands more sustainably.

Tip: Consider the installation environment when selecting a PM motor. High humidity or extreme temperatures can affect performance.

In solar applications, these motors are also valuable. They drive pumps and fans efficiently in solar thermal systems. However, the upfront costs can still be a barrier for some projects. While the long-term savings are appealing, many hesitate due to initial investments. Ongoing technical advancements will likely address these concerns and expand access to renewable technologies.

Tip: Regular maintenance of PM motors can greatly increase their lifespan and efficiency, ensuring optimal performance.