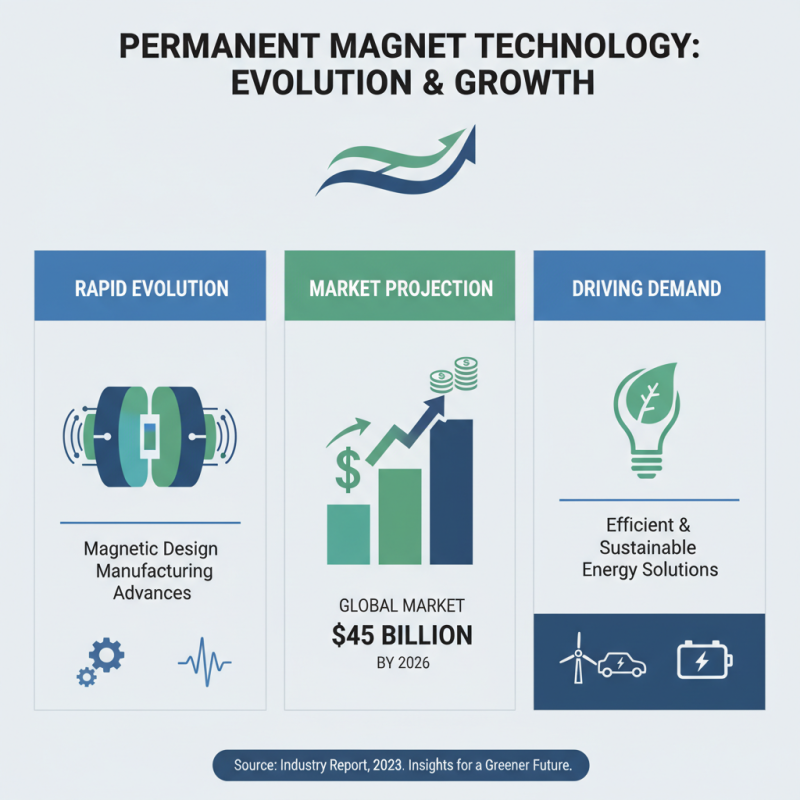

The field of Interior Permanent Magnet (IPM) technology is experiencing rapid transformation. According to a recent report by MarketsandMarkets, the global permanent magnet market is projected to reach $20 billion by 2026. This trend reflects the increasing demand for efficient and compact solutions in various industries, from automotive to renewable energy. As businesses prioritize sustainability, IPM technologies can significantly reduce energy consumption.

Expert Dr. Emily Carter, a prominent figure in the magnetics industry, emphasizes the importance of innovation in this sector. She states, "Advancements in Interior Permanent Magnet design will lead to breakthroughs in efficiency and performance." Companies are investing heavily in R&D to explore new materials and manufacturing techniques. However, there are challenges. The reliance on rare earth elements poses risks to supply chains and sustainability.

Exploring future trends in IPM technology reveals the need for balance. Companies must innovate while also addressing environmental impacts. The push for more sustainable practices might drive a shift in material usage. As the landscape of Interior Permanent Magnet technology evolves, staying ahead will require continuous adaptation and critical reflection on these trends.

Emerging materials have a significant impact on permanent magnet technology. Innovations in rare earth elements and composites are reshaping this field. Researchers explore alternatives to traditional materials. These new options could reduce costs and enhance performance.

Tips for exploring these innovations: Consider their availability. Not all emerging materials are easy to source. Some might also require advanced manufacturing processes. Take time to evaluate these aspects before making decisions.

New developments often come with challenges. Recycling processes for new materials can be complex. Understanding the lifecycle of these materials is essential. Increased focus on sustainability may drive future innovations. Stay updated on advancements to make informed choices.

The landscape of interior permanent magnet technology is rapidly evolving. Advances in magnetic design and manufacturing are at the forefront of this change. A recent industry report predicts that the global permanent magnet market will reach $45 billion by 2026. This growth reflects an increasing demand for efficient and sustainable energy solutions.

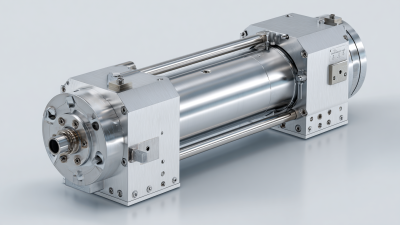

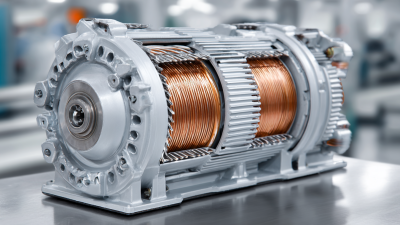

Magnetic design has become more intricate. Engineers are focusing on reducing material waste and improving performance. The use of computer-aided design (CAD) tools now allows for better simulations. Companies have reported up to a 30% improvement in efficiency through optimized designs. However, challenges remain. Many manufacturers struggle to adopt these advancements consistently.

Manufacturing processes are also being refined. 3D printing technology is enabling the creation of complex magnet shapes. This can lead to lighter and more efficient components. A recent study indicated that additive manufacturing can lower costs by 20% in the long run. Yet, not all organizations have the capability to fully utilize this technology. There's a significant gap between potential and practice.

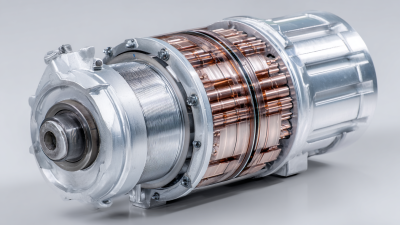

Permanent magnets play a crucial role in renewable energy systems. Their efficiency directly affects energy output. Wind turbines and solar inverters heavily rely on these magnets. The strength of permanent magnets helps in converting kinetic energy into electricity seamlessly. However, the supply chain for rare earth materials raises concerns. Sourcing these materials often poses ethical and environmental challenges.

In photovoltaic systems, permanent magnets enhance performance. They improve the effectiveness of power electronics. This leads to better energy conversion rates. However, the durability of these magnets under extreme conditions requires more research. Performance degradation over time affects efficiency. Engineers must balance magnet strength with cost and sustainability.

Another application is in electric vehicles. Permanent magnets are at the heart of many motor designs. They provide high torque and efficiency. Nevertheless, the reliance on rare earth materials presents risks. Alternative materials or designs could reduce dependency. Innovations are needed to address these challenges effectively. The future of permanent magnet technology in renewable energy remains a vibrant area for exploration.

The trends in miniaturization for consumer electronics and the automotive industries are transforming product design. Devices are becoming smaller, lighter, and more efficient. This shift requires new approaches in interior permanent magnet technology. Smaller magnets can lead to compact motors, enhancing performance while minimizing space.

For consumer electronics, every millimeter counts. A smartphone’s battery life is critical. Magnetic components play a role here. Engineers are exploring ways to maximize energy output while reducing size. This is a delicate balance, and not every approach works as planned. Sometimes, smaller components lead to overheating or reliability issues.

In the automotive realm, electric vehicles demand efficiency. Lightweight magnets create powerful drives without bulk. However, challenges persist in manufacturing these tiny parts. Quality control becomes more complex. As the industry pushes towards greater miniaturization, the pursuit of innovation must be paired with thoughtful reflection on the engineering processes involved.

The demand for sustainable practices in manufacturing is rising. Recycling is becoming essential in magnet manufacturing. Using recycled materials can lower costs and reduce waste. Many manufacturers are exploring ways to incorporate recycled magnets. This shift has its challenges. Not all materials are easy to recycle. The process can be complex and uneven in quality.

Improving the efficiency of recycling methods is crucial. Innovations in technology may lead to better practices. New methods can help in extracting valuable materials from discarded magnets. This is a step towards sustainability. However, not all technologies are viable yet. Research is ongoing, and results are mixed. Some methods show great promise, while others need refinement.

Sustainability must be at the forefront of magnet production. Manufacturers face scrutiny over their ecological impact. The industry must adapt to these expectations. Commitment to recycling can enhance reputation. Yet, there’s a balance to find. Quick fixes might not yield lasting solutions. The road to sustainable magnet manufacturing is long and winding.