In today's industrial landscape, efficiency and reliability are paramount for operational success. The integration of technology in industrial processes has led to significant advancements, particularly with the advent of the Air Suspension Centrifugal Blower. According to a report by the International Society of Automation, facilities that utilize advanced blower systems can achieve up to a 30% reduction in energy consumption compared to traditional blowers. This is crucial in an age where energy costs are consistently on the rise, directly impacting a company's bottom line.

The Air Suspension Centrifugal Blower not only enhances energy efficiency but also contributes to improved performance metrics across various industrial applications. A study by the American Society of Mechanical Engineers highlights that systems employing air suspension technology can reduce maintenance costs by as much as 25%, due to fewer moving parts and less wear and tear. With the industry seeking sustainable solutions, adopting such innovative blower systems aligns with both operational goals and environmental responsibilities, making them an indispensable asset for manufacturers aiming to enhance productivity while minimizing their carbon footprint.

The Air Suspension Centrifugal Blower not only enhances energy efficiency but also contributes to improved performance metrics across various industrial applications. A study by the American Society of Mechanical Engineers highlights that systems employing air suspension technology can reduce maintenance costs by as much as 25%, due to fewer moving parts and less wear and tear. With the industry seeking sustainable solutions, adopting such innovative blower systems aligns with both operational goals and environmental responsibilities, making them an indispensable asset for manufacturers aiming to enhance productivity while minimizing their carbon footprint.

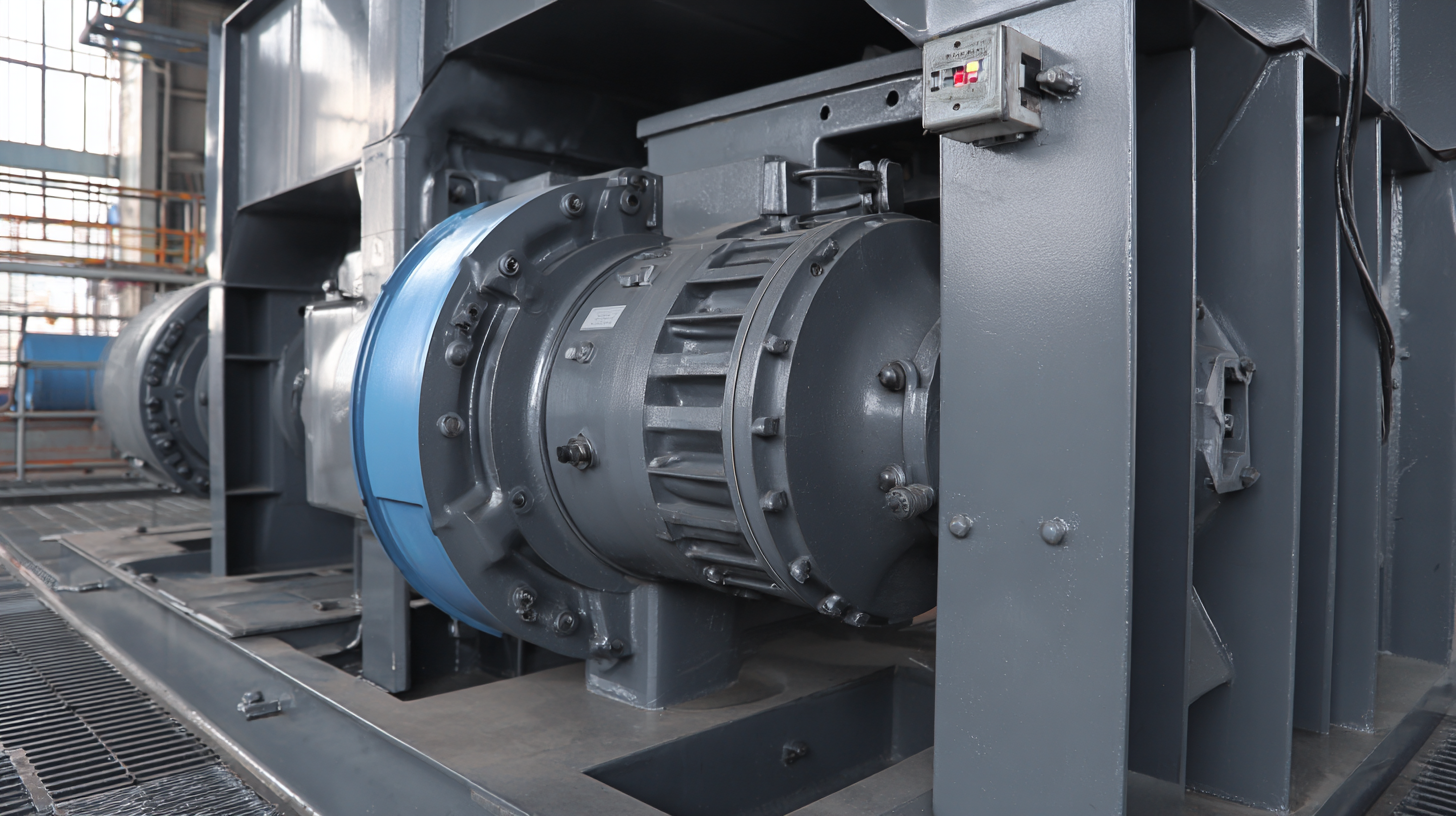

Air suspension technology in centrifugal blowers presents significant advantages that enhance industrial efficiency. One of the primary benefits is the reduction of vibrations, which leads to smoother operation. This enhanced stability not only prolongs the lifespan of the equipment but also minimizes maintenance costs, making it a cost-effective choice for manufacturers. Furthermore, these blowers optimize airflow with precision, resulting in better performance and energy savings, aligning with sustainable production practices.

Another critical advantage of air suspension technology is its adaptability to varying operational conditions. This flexibility allows industries to achieve optimal performance across different processes, enhancing productivity. Additionally, as consumers increasingly demand environmentally friendly packaging and sustainable practices, using air suspension centrifugal blowers supports these initiatives by reducing energy consumption and increasing overall operational efficiency. By integrating such advanced technology, manufacturers can not only meet consumer expectations but also contribute to broader sustainability goals.

In recent years, there has been a significant shift towards enhanced energy efficiency across various industries, driven by the growing emphasis on reducing carbon emissions. Air suspension centrifugal blowers have emerged as a critical technology in this transformation, especially as the global energy transformation system market is projected to grow from $1,829.9 billion in 2024 to $2,349.6 billion by 2032, with a compound annual growth rate (CAGR) of 3.17% during the period from 2024 to 2032. This growth is largely fueled by the increasing adoption of technologies aimed at minimizing energy consumption.

Air suspension centrifugal blowers contribute to improved energy efficiency by utilizing advanced design and materials that minimize operational energy demand. By optimizing airflow dynamics, these blowers not only enhance performance but also lead to substantial cost savings for businesses. The rising recognition of the importance of reducing carbon footprints aligns with the growing market for smart thermostats and other energy-saving devices, indicating that companies are increasingly investing in solutions that promise both environmental and economic benefits as they adapt to heightened climate challenges.

| Benefit | Description | Impact on Efficiency | Potential Savings (%) | Carbon Footprint Reduction (%) |

|---|---|---|---|---|

| Improved Energy Efficiency | Air suspension centrifugal blowers require less energy to operate, leading to lower electricity costs. | Higher operational efficiency due to reduced energy consumption. | 15-30% | 10-20% |

| Noise Reduction | Designed to operate quietly, minimizing noise pollution in industrial environments. | Creates a better working environment, potentially increasing productivity. | N/A | N/A |

| Enhanced Performance | Provides consistent air flow and pressure, crucial for sensitive industrial applications. | Improved product quality and process reliability. | N/A | N/A |

| Lower Maintenance Costs | Air suspension systems have fewer moving parts, resulting in reduced wear and tear. | Less downtime and maintenance effort required. | 10-25% | 5-15% |

| Sustainability Features | Using less energy directly impacts overall greenhouse gas emissions. | Long-term benefits for corporate sustainability goals. | N/A | 20-30% |

Air suspension centrifugal blowers have emerged as a pivotal technology enhancing industrial efficiency, particularly with their ability to maintain consistent airflow and pressure stability. This performance stability is crucial across various applications, especially in air filtration systems that rely on optimal air quality. Recent advancements in nanofibers demonstrate their efficacy in filtration, linked to their high surface area-to-volume ratio, which emphasizes the demand for consistent airflow provided by efficient blowers.

Furthermore, the integration of advanced cooling technologies in industrial settings is essential for maintaining peak performance, akin to the innovations seen in data centers where airflow management is critical. Just as refined thermal designs in computing environments prevent overheating and ensure operational efficacy, air suspension centrifugal blowers contribute to a stable environment for machinery, thus prolonging service life and enhancing operational reliability.

This synergy between innovative blower technology and system performance underscores the importance of airflow and pressure consistency in modern industrial applications.

Air suspension centrifugal blowers have emerged as a game-changer in various industries, particularly when it comes to noise reduction. According to a report by the National Institute for Occupational Safety and Health (NIOSH), prolonged exposure to high noise levels (above 85 dB) can lead to hearing loss and increased stress levels among workers. Traditional blowers often operate at these concerning decibel levels, but air suspension technology can significantly lower noise outputs, enhancing workplace safety and comfort.

A recent study published in the Journal of Industrial Engineering indicates that air suspension centrifugal blowers can reduce operational noise levels by up to 30%. This noise reduction not only fosters a more pleasant working environment but also improves communication among workers, leading to greater efficiency and productivity. With many organizations aiming to prioritize employee well-being, the implementation of quieter blower systems can be a crucial step toward achieving a more harmonious and focused workplace atmosphere.

By minimizing noise-related disruptions, facilities can also extend the lifespan of machinery, as quieter operations often mean reduced vibration and wear. This ensures that operations run smoothly without frequent interruptions for maintenance or repairs, ultimately driving down operational costs and enhancing overall industrial efficiency.

Air suspension centrifugal blowers are becoming indispensable in the industrial landscape, particularly due to their low maintenance requirements. These systems significantly reduce downtime and operational costs, which are critical factors for manufacturers striving for enhanced efficiency. According to industry reports, the average cost of equipment downtime now stands at staggering figures, averaging $260,000 per hour. This highlights the pressing need for reliable machinery that minimizes interruptions.

Moreover, advanced predictive maintenance technologies, powered by AI, have been shown to boost factory uptime by up to 15%. By leveraging these tools, industries can not only predict equipment failure but also address maintenance needs more swiftly and accurately. The integration of these systems with air suspension centrifugal blowers can further streamline maintenance operations, allowing manufacturers to focus on productivity rather than dealing with unexpected equipment failures or costly repairs, ultimately driving higher operational efficiencies in an increasingly competitive market.