The shift towards energy-efficient technologies has become a crucial focus in various industries, particularly in the context of global sustainability efforts. Among the advancements, Permanent Magnet Synchronous Motors (PM Synchronous Motors) have emerged as a key player in enhancing energy efficiency.

According to a report by the International Energy Agency, electric motors account for approximately 45% of global electricity consumption in industrial applications, highlighting the significant potential for energy savings through improved motor technologies.

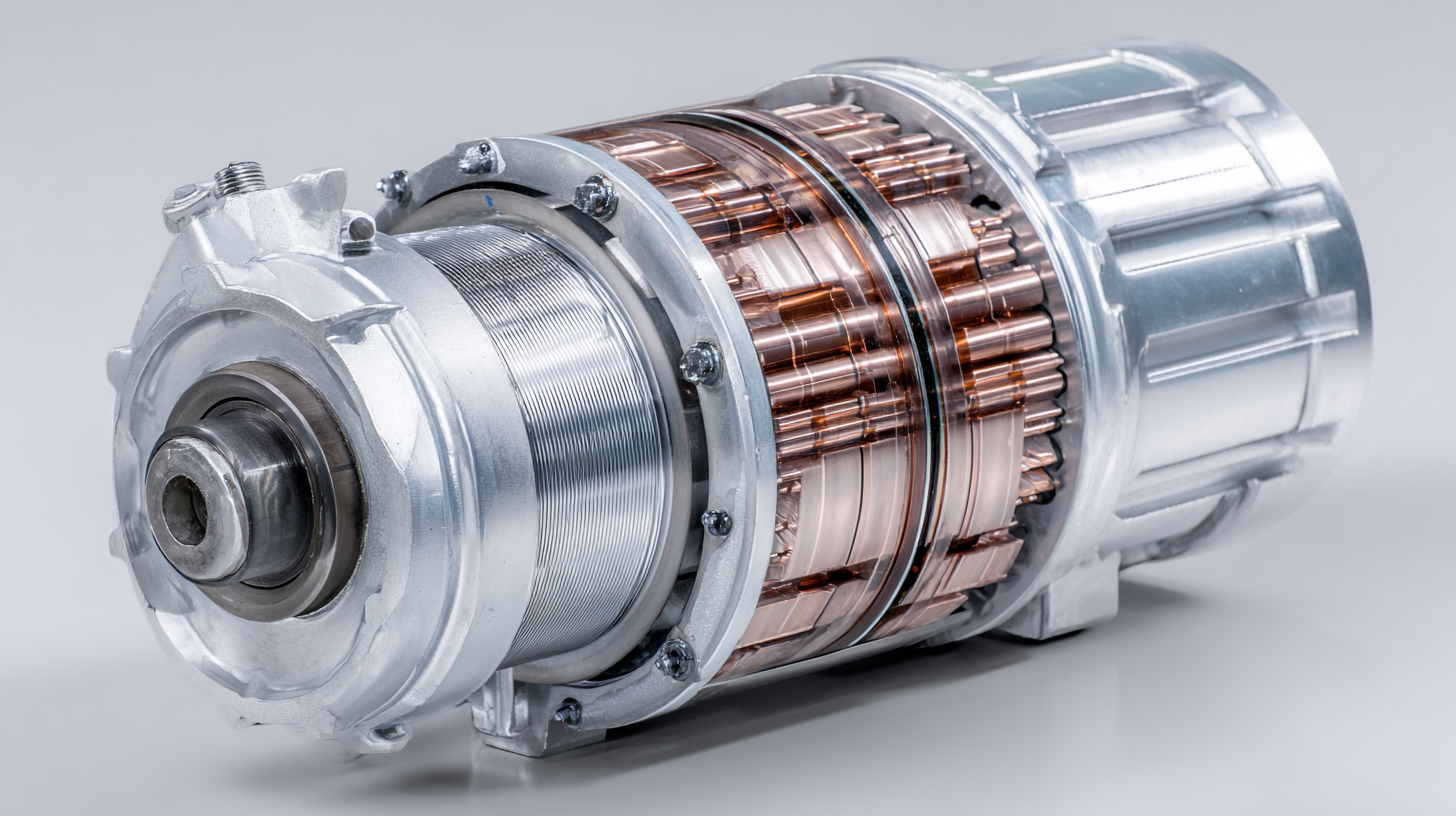

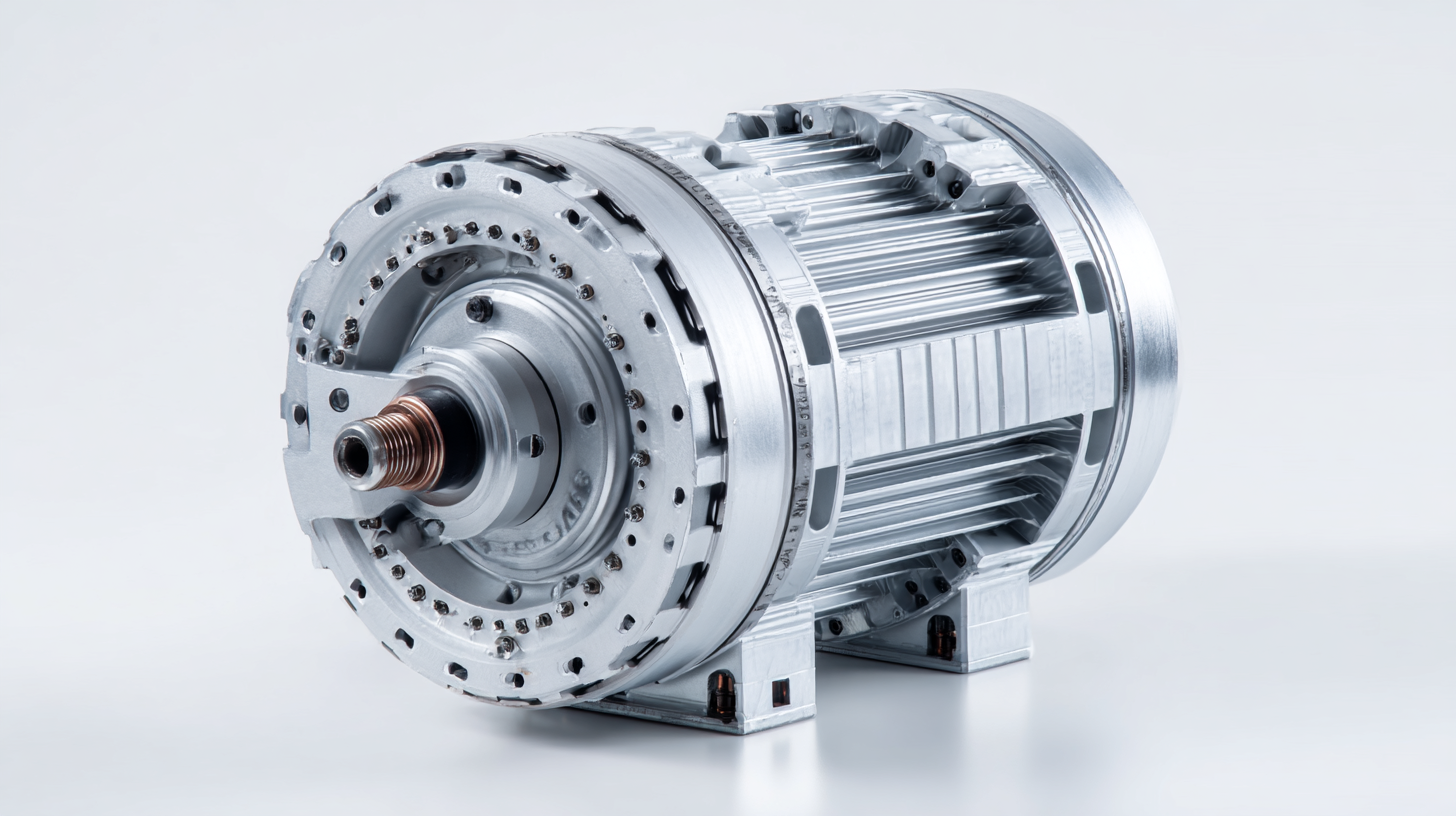

PM Synchronous Motors, known for their high efficiency and performance, can reduce energy consumption by up to 30% compared to traditional induction motors, as documented in recent studies. These motors leverage permanent magnets to ensure high torque density and efficiency, making them ideal for applications requiring precision and reliability.

PM Synchronous Motors, known for their high efficiency and performance, can reduce energy consumption by up to 30% compared to traditional induction motors, as documented in recent studies. These motors leverage permanent magnets to ensure high torque density and efficiency, making them ideal for applications requiring precision and reliability.

As industries strive to reduce their carbon footprint while optimizing operational costs, understanding the benefits of PM Synchronous Motor technology is essential for future energy-efficient solutions.

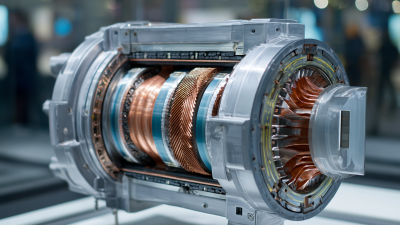

Permanent Magnet (PM) Synchronous Motors (PMSMs) are gaining traction in modern applications due to their unparalleled efficiency and performance. According to a report by the International Energy Agency, electric motors consume approximately 45% of the world’s electricity, highlighting the urgent need for energy-efficient solutions. PMSMs can achieve efficiencies exceeding 95%, significantly reducing energy consumption compared to traditional induction motors. This efficiency translates into lower operating costs and contributes to sustainability efforts in various industries.

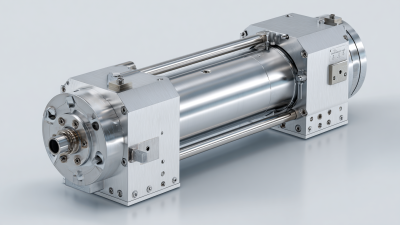

In addition to their energy efficiency, PMSMs offer high power density and a compact design, making them ideal for applications requiring high performance in limited spaces. The U.S. Department of Energy estimates that the adoption of PM synchronous motor technology could result in energy savings of up to 10 terawatt-hours annually in the industrial sector alone. As these motors are increasingly integrated into automation and robotics, their ability to provide precise speed and torque control enhances operational efficiency, further solidifying their role in modern technology advancements.

Permanent Magnet Synchronous Motors (PMSMs) are becoming increasingly vital for enhancing energy efficiency in various applications, particularly in the growing electric commercial vehicle market. This market is projected to reach USD 7.5 billion by 2035, reflecting a remarkable CAGR of 12.7%. PMSMs optimize energy consumption through their operational efficiency and reduced losses, making them a preferred choice for manufacturers seeking to meet stringent energy regulations.

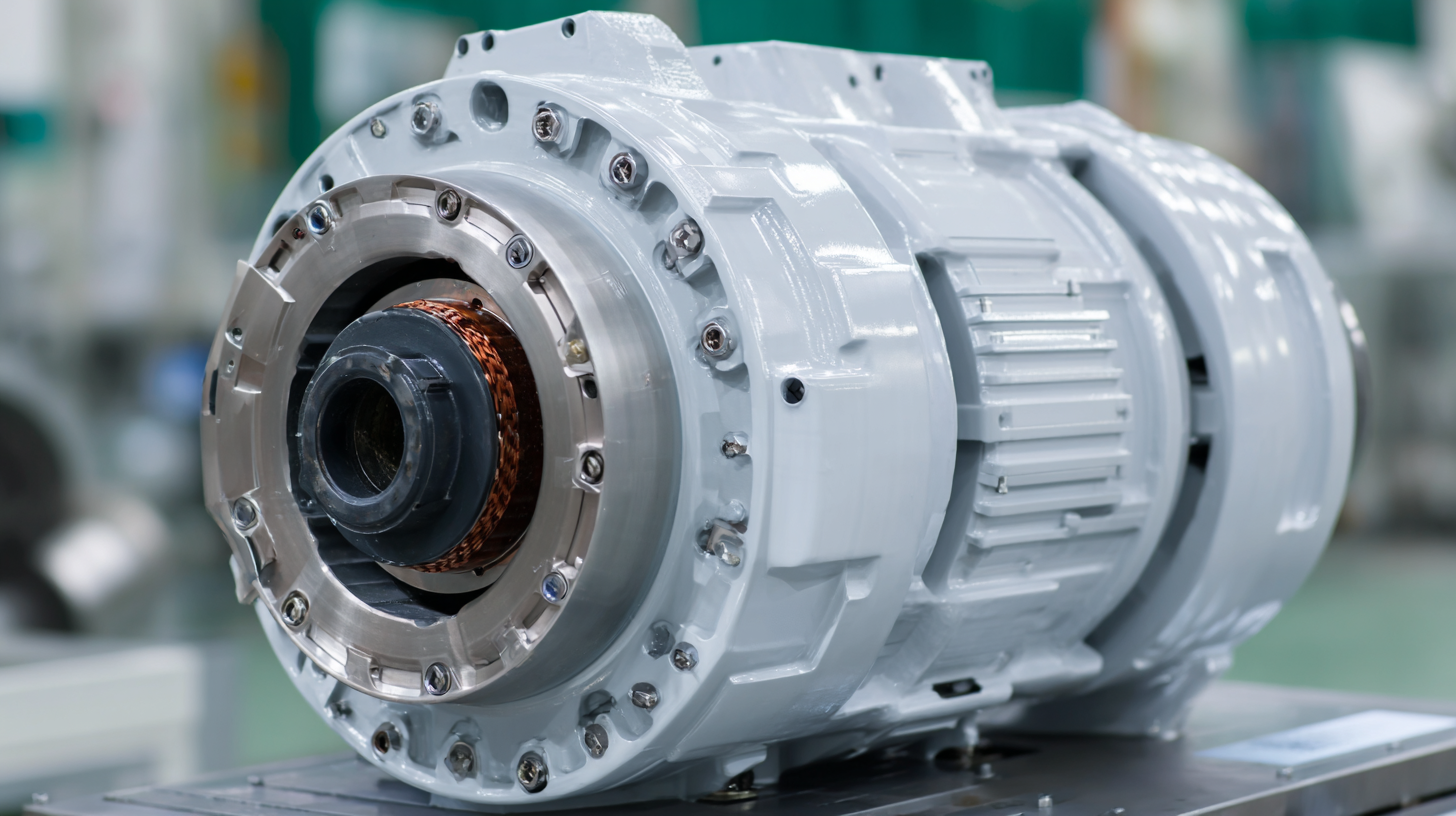

One of the significant advancements in this area is the development of Line-Start Permanent Magnet Synchronous Motors (LSPMSMs). A recent study focused on the design optimization and implementation of LSPMSMs highlights their potential for improved efficiency in real-time applications. This motor technology enables better performance while utilizing less energy, which is crucial as the global motor lamination market is also projected to grow from USD 21.38 billion in 2025 to USD 30.89 billion by 2030.

Tips: When considering a shift to PMSMs for your operations, it’s essential to evaluate the specific energy requirements and pay attention to the integration of design optimization strategies. Investing in advanced motor technology not only contributes to energy savings but also positions your business competitively in a rapidly evolving market.

| Understanding the Benefits of PM Synchronous Motor Technology for Energy Efficiency | |||

|---|---|---|---|

| Parameter | Conventional Motors | PM Synchronous Motors | Efficiency Improvement (%) |

| Energy Consumption (kWh) | 5000 | 3500 | 30% |

| Operating Cost ($) | 2000 | 1400 | 30% |

| Maintenance Cost ($) | 300 | 150 | 50% |

| Lifespan (years) | 10 | 15 | 50% |

| Total Savings Over Lifespan ($) | 24000 | 14500 | 39.58% |

Permanent Magnet (PM) synchronous motors (PMSMs) have emerged as a superior alternative to traditional induction motors in various industrial applications due to their enhanced energy efficiency. According to the U.S. Department of Energy, PMSMs can achieve efficiencies exceeding 95%, while traditional motors typically range between 85% and 92%. This notable difference in efficiency translates into significant energy savings, especially in high-demand settings. The reduced energy consumption contributes not only to lower operational costs but also to a smaller carbon footprint, aligning with global efforts to promote sustainable practices in manufacturing.

Additionally, PMSMs offer improved performance characteristics, such as higher torque density and compact design, which facilitate better integration into modern automation systems. A report from the International Energy Agency (IEA) highlights that the adoption of high-efficiency motors, including PMSMs, could result in a potential energy savings of up to 20% in the industrial sector alone. Furthermore, the ability to maintain a constant speed under varying load conditions makes PM synchronous motors ideal for applications requiring precise control, setting them apart from traditional motors that often struggle with efficiency under load fluctuations. As industries strive for increased productivity and energy conservation, the shift towards PM synchronous motors is becoming increasingly compelling.

The development of Permanent Magnet (PM) synchronous motor technology is significantly influenced by key advancements that enhance energy efficiency across various applications. One notable trend is the escalation of the global motor lamination market, which is projected to grow substantially in the coming years. This growth is propelled by the increasing demand for high-efficiency electric motors, particularly in industries transitioning towards sustainable and energy-efficient technologies.

Additionally, innovative collaborations such as the one between Valeo and MAHLE exemplify the ongoing evolution in electric motor technology. Their joint development of magnet-free electric motors for upper segment applications illustrates the industry's shift towards reducing dependency on rare materials while optimizing performance. This not only enhances the reliability of electric vehicles but also contributes to significant cost savings in operational expenses, making synchronous reluctance motors increasingly appealing for diverse industrial uses. Advanced motor control technologies are also emerging, promising improved performance for a variety of motor types, including brushless DC and PM synchronous motors, underscoring a comprehensive approach to enhancing energy efficiency.

The adoption of Permanent Magnet (PM) synchronous motors is on the rise, reflecting a significant shift towards sustainable energy solutions across various industries. The global motor lamination market, valued at USD 20.68 billion in 2024, is projected to experience substantial growth, reaching USD 30.89 billion by 2028. This trend highlights the increasing demand for energy-efficient technologies, with PM synchronous motors playing a pivotal role in enhancing performance and reducing energy consumption in automotive and industrial applications.

Additionally, rare earth materials are essential in driving innovations within the automotive industry, especially in electric vehicle (EV) technology. These materials serve as critical components in the manufacturing of PM synchronous motors, allowing for compact designs that offer high torque and efficiency. As the industry faces supply chain challenges, the focus on securing a stable supply of rare earth elements becomes increasingly crucial for sustaining technological advancements and supporting the shift towards electrification in transportation. This intersection of motor technology and rare earth materials not only underscores the importance of energy efficiency but also catalyzes the push towards a more sustainable energy future.