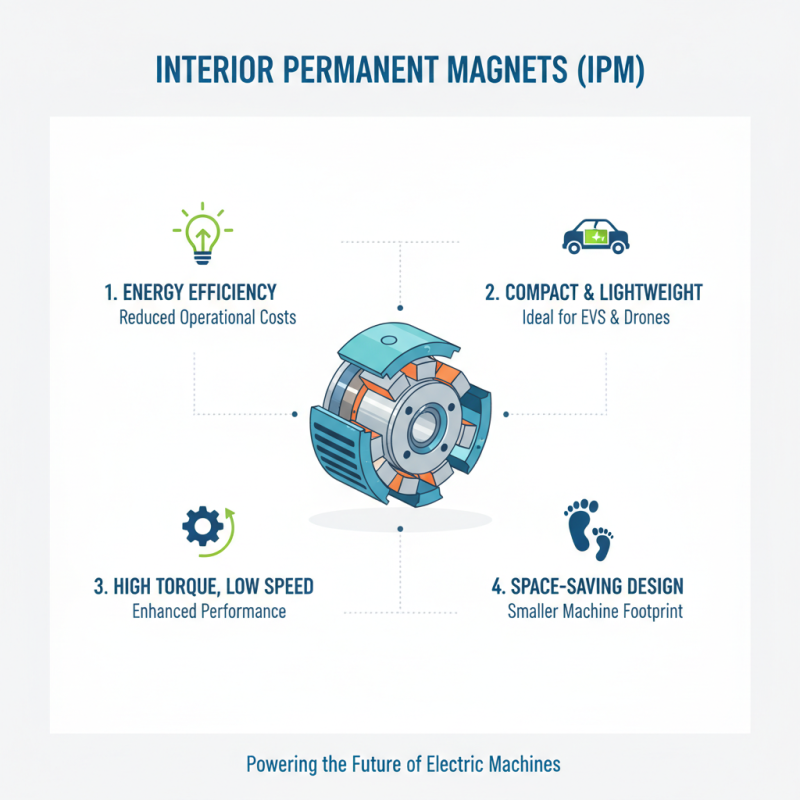

Interior Permanent Magnet (IPM) technology has transformed various industries. These magnets provide high efficiency and performance, making them ideal for a range of applications. The beauty of IPMs lies in their compact design and lightweight nature. This allows for innovative solutions in electric motors, generators, and various consumer appliances.

In automotive applications, IPMs play a crucial role. They enhance electric vehicle drivetrains, promoting energy savings. The benefits extend beyond mere efficiency. The reliance on IPMs encourages manufacturers to push for sustainability. However, their production involves rare earth materials, raising ethical questions about sourcing.

Exploring IPM applications reveals both advantages and challenges. While their performance is impressive, not all IPMs are created equal. Some designs may lead to overheating or reduce lifespan. This is a reminder of the need for ongoing research and reflection in this field. Ultimately, Interior Permanent Magnet technology offers great potential but requires careful consideration of its impact.

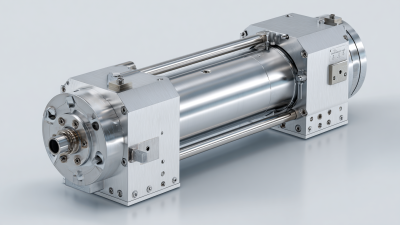

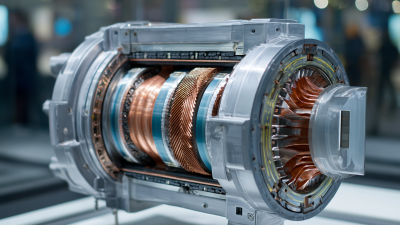

Interior permanent magnets (IPMs) are widely used in various applications due to their unique properties. These magnets are embedded within the motor's rotor, allowing for a compact design. Their strength comes from the alignment of magnetic materials, providing high torque and efficiency. IPMs are commonly found in electric vehicles, where their performance is critical.

However, the effectiveness of IPMs can be influenced by temperature variations. High temperatures may reduce their magnetic strength, leading to efficiency losses. It's important for designers to consider thermal management when implementing these magnets in systems. Despite this challenge, IPMs are favored for their lightweight characteristics and high power density.

Another aspect to ponder is the production process. Manufacturing IPMs often involves complex techniques, raising costs and potential quality issues. Ensuring consistent quality is a constant challenge. Balancing performance, cost, and reliability creates a multifaceted problem for engineers in the field. These considerations highlight the areas where further innovation is needed.

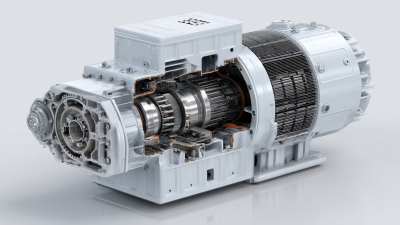

Interior permanent magnets (IPMs) play a crucial role in various industries, showcasing diverse applications. In automotive sectors, IPMs are vital for electric vehicle (EV) motors. These motors are more efficient and compact than traditional alternatives. According to industry reports, the global electric vehicle market is expected to grow by over 20% annually. This growth indicates a rising demand for efficient motor solutions.

In industrial machinery, interior permanent magnets significantly enhance the performance of servo motors. These motors exhibit high torque and efficiency, crucial for precision tasks. Recent studies have shown that using IPMs can improve energy efficiency by up to 30%. Such improvements are essential as industries aim to reduce energy consumption and operational costs.

However, reliance on rare earth materials poses challenges. Sourcing these materials can lead to supply chain issues and price fluctuations. Companies must rethink their strategies, balancing performance with sustainability. IPMs are great, but their environmental impact needs careful consideration. A holistic approach is essential for the future of industries utilizing interior permanent magnets.

Interior permanent magnets (IPMs) play a crucial role in modern electrical machines. Their compact design allows for more efficient use of space inside motors. A smaller footprint means lighter devices. This feature helps in applications like electric vehicles, where weight matters. The use of IPMs can lead to improved energy efficiency, reducing overall operational costs. These magnets help achieve high torque at low speeds, enhancing performance across various conditions.

Tips: Consider the arrangement of IPMs. Magnetic field orientation can significantly affect performance. Experimenting with configurations might lead to unexpected benefits.

The unique benefits of IPMs stem from their design. These magnets provide high rotor flux density. This characteristic results in better performance under dynamic conditions. However, the cost of IPM technology can be higher compared to traditional magnets. It's essential to weigh the initial investment against long-term savings.

Tips: Conduct thorough cost analysis before implementing IPMs. Look for trade-offs that could impact your budget. Sometimes the best choice isn't the most obvious one.

Interior permanent magnets (IPMs) have unique properties that make them advantageous in various applications. These magnets are known for their high magnetic field strength and efficiency. They are commonly used in electric motors and generators. Compared to traditional magnets, IPMs offer increased torque in smaller sizes. This makes them ideal for compact devices. Their robust performance often leads to energy savings.

However, there are challenges when comparing IPMs with softer magnetic materials. IPMs can be more expensive to produce. Their manufacturing processes require precise techniques. This can lead to longer lead times. In comparison, softer magnets may not perform as well but are cheaper and easier to source. Each has a place in industry, but the choice depends on application needs.

The use of IPMs might not always be the best option. In certain situations, the performance gains may not justify the costs. There may be cases where other magnets perform adequately. It’s essential to analyze specific requirements. Understanding strengths and weaknesses of each type can lead to better decision-making.

Interior permanent magnets (IPMs) are gaining traction in various applications. Their compact size and efficiency make them ideal for motors and generators. One trend is the shift toward higher energy density magnets. This offers potential for smaller, lighter devices without sacrificing performance. Innovations in material science could lead to better magnetic properties and temperature stability.

Future advancements may also focus on sustainability. Producing magnets with less environmental impact is increasingly important. Recycling old magnets is another area to explore. Still, challenges remain in scaling these processes effectively. Some applications might still rely on traditional materials for a while.

The digitalization of manufacturing could influence IPM technology. Automation and AI can optimize designs, leading to novel configurations. However, the path to widespread adoption isn't straightforward. Compatibility with existing technologies needs careful consideration. Overall, while the future looks promising, reflection on these hurdles is vital.