The Hammer Crusher industry is rapidly evolving, making it essential for buyers to stay informed. According to a recent market analysis by Global Industry Analysts, the demand for Hammer Crushers is projected to grow by over 5% annually through 2026. This significant growth is driven by the rising needs in mining and construction sectors.

Expert in the field, Dr. John Smith, states, “Investing in the right Hammer Crusher not only enhances productivity but also significantly reduces operational costs.” This highlights the importance of selecting the appropriate equipment. Consumers must navigate numerous options, ensuring quality and durability.

However, many buyers overlook critical factors, such as maintenance requirements and adaptability. Evaluating these aspects can be challenging. Yet, understanding them is vital for making informed purchasing decisions. Investing time into research will likely lead to successful outcomes.

Hammer crushers play a crucial role in various industries. They are designed to crush materials like coal, salt, and gypsum. These machines rely on a rotating hammer or hammers to pulverize the material into smaller pieces. Understanding how these crushers work can significantly impact your purchasing decision.

There are different types of hammer crushers. Some are suitable for soft materials, while others handle harder substances. Knowing the material you will be working with is essential. Consider the size of the particles you need. Larger fragments may require a more robust machine. Analyze the crusher's specifications deeply, as one size does not fit all.

When selecting a hammer crusher, think about your needs. Look for machines with adjustable settings. This allows you to customize the output. Efficiency is also vital. A well-designed crusher can save you time and costs. Don’t rush into buying the first one you see. Compare features and capabilities. This will help you make an informed choice.

When considering a hammer crusher, several key features are crucial. First, the size of the crushing chamber matters. A larger chamber allows for the processing of bigger materials. This can improve efficiency but may require more space in your facility. Assess your material size and choose accordingly.

Another important aspect is the rotor speed. Higher speeds can lead to finer materials but can also increase wear and tear. You should evaluate the trade-offs between speed and maintenance costs. Additionally, consider the type of hammers used. Different materials can affect the durability and performance of the crusher. Ensure that the hammers are easily replaceable to minimize downtime.

Power consumption is another factor worth examining. A hammer crusher can consume significant energy. It's wise to weigh the energy costs against productivity gains. Don’t forget the safety features as well; these ensure not just worker safety but also the longevity of the equipment. Every choice involves a compromise. Consider your priorities carefully to make an informed decision.

When evaluating hammer crushers, performance metrics like capacity and efficiency are vital. A well-designed hammer crusher can offer a capacity range from 20 to 300 tons per hour, depending on the material. For instance, in the mining sector, a typical unit can handle abrasives and hard rocks effectively. However, the choice of hammer design affects output significantly.

Efficiency metrics often include the rotor speed and the structural integrity of the hammers. Industry reports indicate that rotor speeds of 300 to 800 RPM yield optimal performance. Some crushers operate best at lower speeds, reducing wear on components. Yet, performance may be compromised if speed is not adjusted to the specific material being processed. This necessitates ongoing assessment of equipment conditions.

User feedback frequently reveals a need for sensitivity to changing material loads. High capacity does not always equate to high efficiency. Some operators report excessive power consumption without proportional output. This highlights the importance of balancing hammer design and operational practices to maximize productivity while minimizing costs. An ongoing evaluation of these parameters can uncover inefficiencies that deserve attention.

Maintaining a hammer crusher is crucial for its longevity and optimal performance. Regular checks on the hammer heads are essential. Inspect them for wear and tear. You'll often notice uneven wear patterns, which can affect efficiency. Replacing worn hammers promptly prevents further damage to the rotor and casing.

Lubrication is another vital aspect. Often overlooked, it ensures smooth operation. Use appropriate lubricants as specified in the manual. Over-lubrication can lead to grease build-up, which creates issues. Keeping the bearings clean and well-lubricated drastically reduces friction and heat generation.

Lastly, operators should monitor output levels closely. Sudden drops may indicate underlying problems. Take time to assess the operational parameters. Neglecting these can lead to cascading failures. Check for any unusual vibrations or sounds during operation. Addressing small issues before they escalate is key to extending the life of your hammer crusher.

| Criteria | Description | Importance Level |

|---|---|---|

| Material Type | Choose a crusher designed for the materials you will be processing. | High |

| Crushing Capacity | Determine the required throughput based on your production needs. | High |

| Motor Power | Assess the power requirements for efficient operation. | Medium |

| Maintenance Ease | Select a model that allows for easy maintenance and parts replacement. | High |

| Safety Features | Look for built-in safety mechanisms to protect operators. | Critical |

| Price | Evaluate your budget while considering the total cost of ownership. | Medium |

| Warranty and Support | Check the warranty period and availability of customer support. | High |

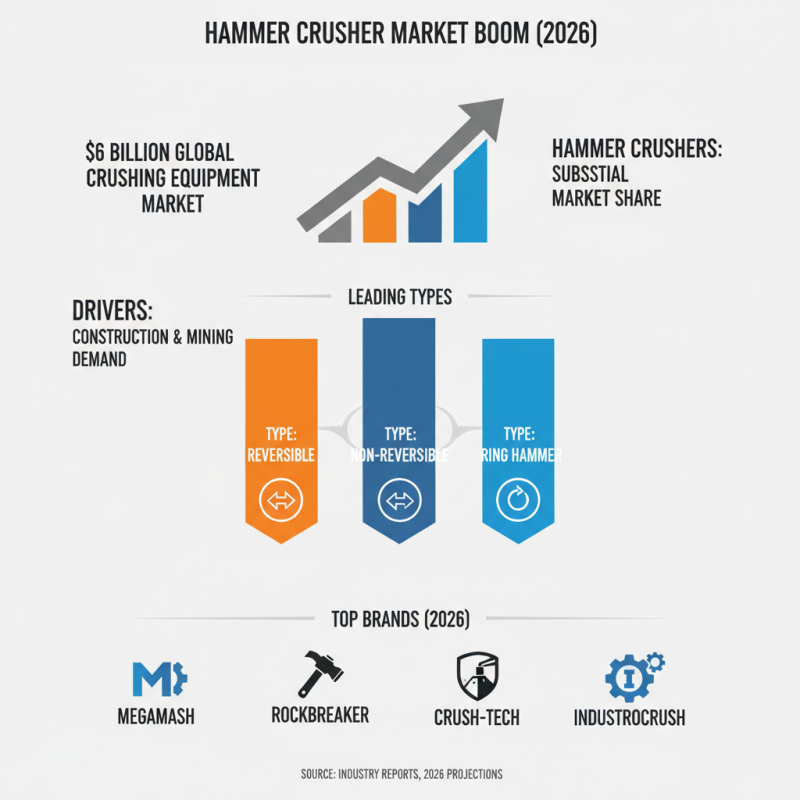

In 2026, the market for hammer crushers is expected to grow significantly, driven by increasing demands in the construction and mining sectors. Industry reports highlight that the global crushing equipment market is projected to reach around $6 billion by 2026, with hammer crushers accounting for a substantial share. Understanding the leading types and brands will be essential for any buyer.

Key models in the hammer crusher category are noted for their efficiency and durability. Many of these models feature innovative technologies that enhance performance. For example, some come equipped with advanced rotor designs that ensure better material processing. However, it’s remarkable that not all models meet robustness standards. Some buyers have reported issues with wear and tear in less mainstream options. This can lead to increased maintenance costs.

Choosing the right hammer crusher involves evaluating various factors. One crucial aspect is the maximum throughput capacity. Models vary significantly, with some capable of handling over 100 tons per hour, while others fall short. Additionally, the material composition of the crushers can impact their long-term viability. Industry data suggests that lightweight models may not offer the same longevity as heavier counterparts. Buyers need to weigh these considerations carefully.