As the Cement Industry Roller Sleeve continues to evolve, it plays a crucial role in the dynamics of the global cement market, particularly ahead of significant events like the 2025 China Import and Export Fair. This event, recognized as one of the largest trade fairs in the world, is set to provide a pivotal platform for industry stakeholders to showcase innovations and emerging trends.

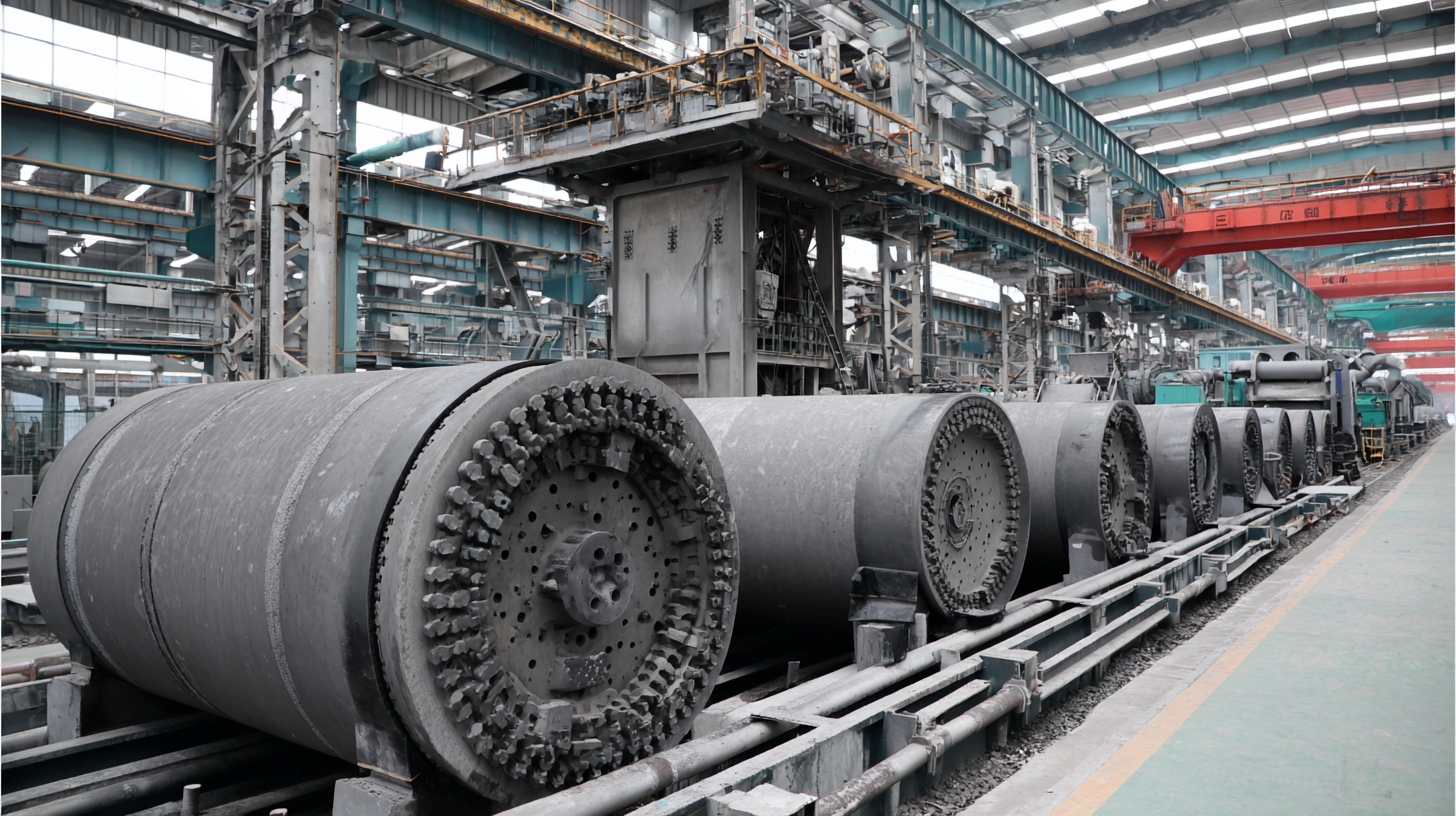

The roller sleeve, an essential component in the cement production process, is witnessing advancements that promise to enhance efficiency and sustainability within the industry. With growing environmental concerns and the demand for high-quality cement products, understanding the latest developments surrounding the Cement Industry Roller Sleeve will be vital for manufacturers and exporters alike.

As we approach the fair, an exploration of these trends will illuminate the potential for improved operational practices and stronger international trade relations in the cement sector.

The roller sleeve, an essential component in the cement production process, is witnessing advancements that promise to enhance efficiency and sustainability within the industry. With growing environmental concerns and the demand for high-quality cement products, understanding the latest developments surrounding the Cement Industry Roller Sleeve will be vital for manufacturers and exporters alike.

As we approach the fair, an exploration of these trends will illuminate the potential for improved operational practices and stronger international trade relations in the cement sector.

The cement industry's evolution is increasingly influenced by innovative technologies, particularly concerning roller sleeves utilized in production processes. Recent reports highlight a significant surge in demand for advanced roller sleeve solutions, estimating the global market to reach $5.4 billion by 2025, propelled by a projected growth rate of 6.3% annually. These innovations are crucial for enhancing efficiency and sustainability in cement manufacturing, where precision and durability are paramount.

One of the key emerging trends is the development of composite roller sleeves designed to withstand high wear and tear while minimizing maintenance costs. Research indicates that using such advanced materials can extend the operational life of roller sleeves by up to 30%, leading to reduced downtime and enhanced productivity. Furthermore, advancements in manufacturing techniques, like additive manufacturing and automation, are paving the way for tailored roller sleeve designs that meet specific operational conditions of each cement plant. These innovations not only contribute to lower energy consumption but also address environmental concerns by reducing waste in production cycles, aligning with global sustainability goals.

| Innovation Type | Description | Benefits | Projected Impact by 2025 |

|---|---|---|---|

| Enhanced Material Composition | Use of advanced composites to improve durability and performance. | Longer lifespan, reduced maintenance costs. | Increase in operational efficiency and reduced downtime. |

| Smart Sensors | Integration of IoT devices for real-time monitoring. | Immediate feedback on performance, proactive maintenance. | Higher productivity and reduced failure rates. |

| Eco-Friendly Materials | Use of recycled and sustainable materials in production. | Reduced carbon footprint and environmental impact. | Compliance with stricter environmental regulations. |

| Advanced Coating Technologies | Development of specialized coatings to enhance performance. | Increased wear resistance and efficiency. | Potential for significant cost savings in material usage. |

| Automation and Robotics | Implementation of automated systems for improved precision. | Higher production rates and reduced labor costs. | Transformation of workflow dynamics in cement production. |

The cement industry is increasingly recognizing the importance of

sustainability practices, particularly in the context of roller sleeves. As a critical

component in cement production processes, roller sleeves contribute significantly

to operational efficiency and energy consumption. By adopting sustainable materials

and manufacturing practices for roller sleeves, companies can

reduce their environmental footprint while enhancing

product longevity. This shift not only aligns with global sustainability goals but also

responds to growing consumer demand for eco-friendly products.

Tips: When selecting roller sleeves for your cement operations, consider

those made with recycled materials or innovative

composites that minimize energy use during production. Regular maintenance

of roller sleeves can also extend their lifecycle, ensuring better

performance and less waste.

Moreover, companies are exploring advancements in technology to improve

the performance of roller sleeves. Innovations such as optimized design and

surface treatments can lead to less wear and tear, contributing to reduced

resource consumption over time. Embracing such advancements not only aids

in sustainable practices but also enhances productivity, resulting in overall

cost savings for cement manufacturers.

Tips: Engage with suppliers who prioritize sustainability in their operations.

Establishing partnerships with those who share a commitment to eco-friendly

innovations can boost your company's green credentials and operational efficiency.

The roller sleeve market in China is experiencing significant transformation, driven by advancements in manufacturing technologies and increasing environmental regulations. The demand for high-performance roller sleeves is rising, as cement manufacturers seek to enhance efficiency and reduce wear in their production processes. Factors such as the growing adoption of automation and smart manufacturing are shaping the competitive landscape, leading to innovations in design and materials used for roller sleeves.

Additionally, upcoming regulations aimed at minimizing carbon emissions are prompting companies to invest in sustainable solutions. This shift not only influences the types of roller sleeves produced but also encourages collaboration among industry players to develop eco-friendly offerings. As the 2025 China Import and Export Fair approaches, the competitive dynamics are likely to intensify, with major players competing to showcase their latest innovations and secure a stronger market position. The focus on quality, sustainability, and advanced technology will be crucial for companies looking to thrive in this changing landscape.

As the 2025 China Import and Export Fair approaches, the demand for roller sleeves in the cement industry is projected to experience significant growth. This trend is underscored by innovations in manufacturing technology and a heightened focus on sustainability. With the increasing emphasis on energy-efficient production processes, businesses are likely to seek roller sleeves that enhance operational efficiency and reduce waste.

**Tips**: Companies looking to stay ahead of the curve should invest in research and development to create roller sleeves that not only meet current industry standards but also anticipate future regulatory requirements. Collaborating with suppliers to source high-quality materials can also improve product durability, thereby meeting the rising consumer expectations for longevity and performance.

Moreover, the expansion of green construction projects and the push for eco-friendly materials will further propel roller sleeve demand. As stakeholders in the cement industry adapt to these emerging trends, they must remain agile and responsive to shifting market dynamics. Engaging with industry experts and participating in relevant workshops at the Import and Export Fair will provide valuable insights into best practices and innovative solutions in roller sleeve applications.

The cement industry is currently facing significant regulatory shifts that are reshaping supply chains and trade dynamics. The introduction of stricter environmental regulations aimed at reducing carbon emissions presents both challenges and opportunities for players in the sector. Companies must adapt to these regulatory frameworks to maintain compliance while also exploring innovative production techniques. This regulatory landscape is influencing procurement strategies, encouraging businesses to source raw materials locally to minimize transportation-related emissions.

As the 2025 China Import and Export Fair approaches, companies will need to reassess their international trade strategies. Tariffs, trade agreements, and environmental standards will play critical roles in determining the feasibility of cross-border transactions. Enhanced collaboration with international partners will be essential to navigate these complexities, as firms seek to optimize their supply chains and ensure sustainability. The evolving regulatory environment will ultimately demand a more agile and responsive approach, as stakeholders in the cement industry strive to align with global sustainability goals while maintaining competitive pricing and product quality.