Centrifugal Exhaust Fans play a crucial role in various industrial applications. They help remove stale air, fumes, and pollutants from working environments. For optimal performance, these fans require careful consideration in design and installation.

Selecting the right Centrifugal Exhaust Fan involves more than just picking a model. Factors such as airflow, pressure drop, and noise levels matter significantly. Regular maintenance is also essential to ensure longevity and efficiency. Skipping this can lead to poor performance.

Users often overlook simple adjustments that can enhance fan efficiency. For instance, ensuring proper duct size and layout can make a difference. A well-placed fan can achieve better airflow. Reflecting on these details can lead to improved outcomes in fan performance and energy savings.

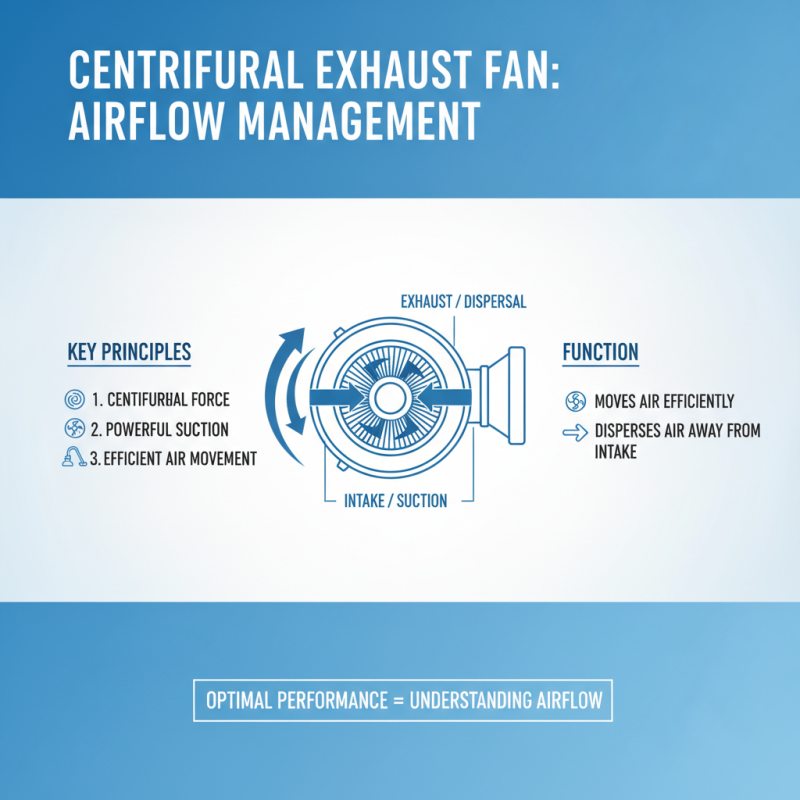

Centrifugal exhaust fans play a crucial role in managing airflow. They create a powerful suction that moves air efficiently. These fans operate on the principle of centrifugal force, which helps to disperse air away from the intake. Understanding how these fans work is essential for optimal performance.

For effective use, installation location matters. Placing the fan close to the area needing ventilation improves efficiency. However, many people overlook this aspect. Ignoring proper placement can lead to decreased airflow and increased energy costs. Users should also ensure the ductwork is clean; clogs can hinder performance significantly.

Regular maintenance is essential, too. Dust and debris can accumulate over time. This buildup may affect the fan's motor and blades. A fan that doesn’t run smoothly can be less effective. Simple checks every few months help maintain efficiency. It’s easy to forget, but this step is vital for prolonged operation.

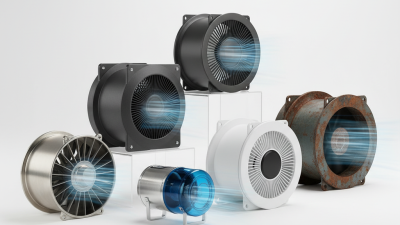

When designing centrifugal exhaust fans, optimal performance hinges on several key features. The impeller design plays a significant role in airflow efficiency. A backward-curved impeller can enhance performance by minimizing turbulence, thus improving the airflow rate by as much as 10% in certain applications. Efficient blade angles also contribute to this, with appropriate adjustments allowing for better pressure generation and energy use.

Another critical aspect is motor selection. Using high-efficiency motors can reduce energy consumption by 30% to 50%. These motors often operate cooler, leading to a longer lifespan and lower maintenance costs. Moreover, proper sizing of the fan is essential. An oversized fan can waste energy and create noise, while an undersized fan may struggle, leading to potential overheating or failure.

Regular maintenance is vital for sustained efficiency. Clogged filters and dirt on blades can cut efficiency by 20% or more. Therefore, implementing a routine check is necessary to ensure desired performance levels. This focus on design features and maintenance can make a substantial difference in operational costs and effectiveness, encouraging a reflective approach to fan usage in industrial settings.

| Design Feature | Description | Impact on Efficiency | Recommended Type |

|---|---|---|---|

| Blade Design | Aerodynamically optimized blades reduce drag and improve airflow. | Enhances efficiency by up to 15%. | Backward-curved blades |

| Fan Size | Larger fans can move more air with less energy consumption. | Increases airflow efficiency, reducing operational costs. | High-volume fans |

| Motor Efficiency | Using energy-efficient motors (e.g. EC motors). | Can decrease energy consumption by 20%-30%. | Electronically Commutated Motors (EC) |

| Inlet Design | Smooth inlet transitions reduce turbulence and enhance airflow. | Improves efficiency by 10%. | Flared or conical inlets |

| Speed Control | Variable speed drives allow flexibility in operation based on demand. | Can save up to 50% in energy costs. | EC motors with VFD |

When choosing an exhaust fan, several factors play a crucial role. Efficiency is key. High-efficiency models can decrease energy costs significantly. According to the U.S. Department of Energy, improving ventilation can save up to 30% on energy usage. It's essential to consider the appropriate CFM (Cubic Feet per Minute) rating. This measurement determines the volume of air the fan can move. Selecting a fan that matches the space's needs is vital to avoid issues like inadequate airflow or excessive noise.

Tips for optimal performance include regularly cleaning the fan blades and housing. Dust accumulation can reduce efficiency by up to 20%. Ensure proper sizing of the fan for the specific application. Over or under-sizing can lead to poor performance. Balance between noise level and airflow is also vital. Many users prefer quieter operations, which often require larger blade designs for reduced RPMs.

Another critical factor is the fan's build quality. Robust materials can enhance durability. Some fans offer weather-resistant options for outdoor installations. Pay attention to the motor type as well. Permanent split capacitor motors tend to be more efficient and have a longer lifespan. Balance all these variables to select the right exhaust fan for your needs.

Maintaining centrifugal exhaust fans is essential for ensuring optimal performance and efficiency. Experts suggest that regular inspections should occur at least every three months. During these inspections, check for signs of wear, dust build-up, and any unusual noises.

A study by the National Institute of Standards and Technology found that proper maintenance can improve fan efficiency by up to 15%. This increase can result in significant energy savings over time.

Cleaning the fan and its components is crucial. Dust and debris can obstruct airflow, leading to decreased efficiency. According to the American Society of Heating, Refrigerating and Air-Conditioning Engineers, maintaining clean components can boost fan performance by nearly 20%. Use appropriate cleaning materials to avoid damaging the fan. Additionally, lubricate bearings regularly to prevent friction, which can shorten the fan’s lifespan.

Monitoring the operating environment is also significant. Factors like humidity and temperature can affect fan performance. Sometimes, fans run too hot, which can be a warning sign. If a fan frequently overheats, it may not function well. Implementing a temperature monitoring system can provide real-time feedback.

This awareness allows for timely adjustments that can improve overall efficiency. Ignoring these aspects might lead to unexpected failures and costly repairs. Regular maintenance and careful monitoring are vital steps toward preserving fan performance.

Centrifugal exhaust fans play a crucial role in many industrial applications. However, issues can arise that impact performance. Common problems include reduced airflow, excessive noise, and overheating. According to industry reports, poor maintenance can lead to a 20% drop in efficiency. Regular checks are essential to keep these fans running smoothly.

One frequent issue is the accumulation of dust and debris. This buildup can severely restrict airflow. Using a vacuum to clean the fan blades can restore efficiency. Another often-overlooked aspect is motor health. A worn-out motor can increase energy consumption by up to 30%. Regular lubrication and inspection can prolong motor life.

Unexpected vibrations are also a concern. These can signal misalignment or wear. Addressing vibrations promptly helps prevent costly repairs. Simple solutions like checking the fan blades and motor mount can mitigate this risk. It's vital to track operational noise levels as well. Increased noise often indicates a problem that needs immediate attention.