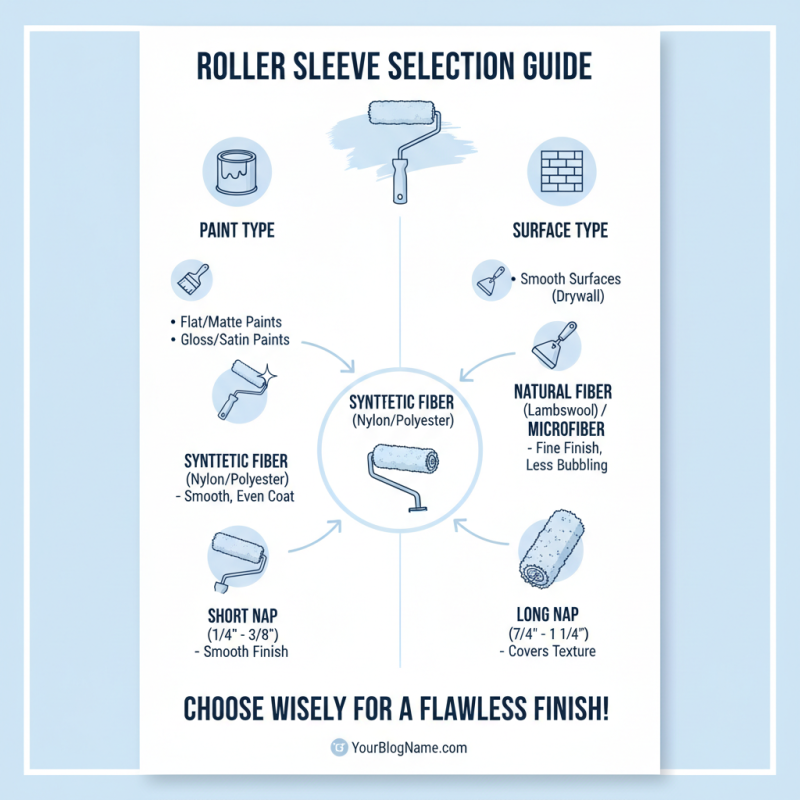

Choosing the right roller sleeve is crucial for your painting project. A good roller sleeve can make or break your finish. It determines how smooth and even your paint application will be. You might wonder, what makes one roller sleeve better than another?

Different surfaces require specific textures. For example, a short nap sleeve works well on smooth walls. However, a longer nap is needed for textured surfaces. It’s essential to consider the paint type too. Some materials pair better with specific paints. Knowing these details can improve your results.

Preparing for your project includes understanding the options available. A poor choice can result in uneven paint coverage. You may even need to apply multiple coats. Reflecting on your previous experiences can help guide your decision. Investing time in selecting the right roller sleeve pays off in the end. Your walls will thank you for it.

Choosing the right roller sleeve can greatly impact the outcome of your painting project. Roller sleeves come in various materials and nap lengths, each serving different purposes. For example, natural fiber sleeves, like lamb’s wool, absorb paint well and release it evenly. Synthetic options, such as polyester and nylon, are easier to clean and provide a smooth finish.

Data from industry reports suggest that 70% of professionals prefer using rollers for large surfaces due to their efficiency. The nap length is crucial; a longer nap is suitable for textured surfaces, while a short nap is ideal for smooth walls. When in doubt, choose a medium nap, around ⅜ inch, which suits most projects.

Tip: Always match the roller sleeve to the paint type. For thick paints, opt for a thicker sleeve. Additionally, consider your surface texture. Testing a small patch before starting can save time and frustration. Remember, it’s essential to replace worn sleeves. A frayed edge can compromise your work’s uniformity and lead to streaks.

Choosing the right roller sleeve for a painting project is crucial. Different projects require specific roller types and materials. One of the primary factors to consider is the texture of the surface. For smooth surfaces, a short nap roller sleeve is generally more effective. A thicker nap is better suited for textured walls. According to industry reports, using the correct nap can reduce paint use by approximately 15%.

Another essential aspect is the fabric of the roller sleeve. Synthetic fabrics often work well with latex paints, while natural fibers are preferable for oil-based paints. Industry studies suggest that using the wrong material can lead to uneven distribution and finish issues. For example, a smooth finish may require more frequent touch-ups if the wrong sleeve is chosen.

Additionally, project scale is a determining factor. Smaller jobs might not warrant a high-priced, specialized roller. However, large surfaces may benefit significantly from more expensive, high-quality options. Many painters find themselves stuck choosing budget sleeves, only to face more extensive rework later. Always consider the potential pitfalls when selecting roller sleeves for your projects.

| Factor | Description | Recommended Use |

|---|---|---|

| Material | Roller sleeves are made from various materials including synthetic fibers, natural fibers, and foam. | Choose synthetic for water-based paints, natural for oil-based paints, and foam for smooth finishes. |

| Nap Length | The nap length refers to the texture of the roller sleeve, which can vary from short to long. | Short nap (1/4" to 3/8") for smooth surfaces; medium nap (1/2") for semi-smooth; long nap (3/4" and above) for rough surfaces. |

| Length | Roller sleeve lengths typically range from 9 to 18 inches. | 9-12 inches for small projects; 18 inches for larger surfaces. |

| Core Size | The core size affects compatibility with roller frames. | Standard core (1"-1.5") for most frames; consider the frame specs before purchasing. |

| Cost | Pricing varies based on material and size. | Budget options for one-time projects; premium sleeves for durability in repeated use. |

Choosing the right roller sleeve is crucial for achieving a smooth finish. Different paint types and surfaces require specific materials for optimal results. For instance, if you are using flat or matte paints, a roller sleeve made from synthetic fibers is often ideal. These materials hold the paint well and deliver an even coat.

On the other hand, when working with textured surfaces, consider opting for a roller sleeve with a thicker nap. This allows it to reach into crevices, covering the surface efficiently. However, be cautious—using a heavy nap with a flat paint can lead to drips and uneven coverage. It’s essential to test a small area first.

Ultimately, selecting a roller sleeve demands careful consideration of both paint and surface type. Mismatching these can spoil your hard work. A quick reflection on your techniques may reveal areas for improvement. Experimentation can lead to valuable insights, but you must be willing to learn from mistakes.

Choosing the right nap size for your roller sleeve is crucial for achieving a smooth finish. The nap size affects how much paint the roller picks up and how it applies to the surface. For smooth surfaces, like drywall, a short nap of 1/4 to 3/8 inch works well. For textured surfaces, a medium nap of 1/2 inch to 3/4 inch is better. A long nap, over 1 inch, is best for very rough surfaces, like brick or concrete.

Tips: Test your roller sleeve on a small area. Watch how the paint flows. You may need to adjust based on your needs. Thicker naps hold more paint but may leave a textured finish, which you might not want.

Sometimes, choosing a nap size can be tricky. The room's lighting can also affect your finish. Paint may appear uneven in certain lights. Experimentation can lead to better results. Be aware of the texture underneath. Rolling too fast can lead to drips. Use even pressure, and you'll see a difference.

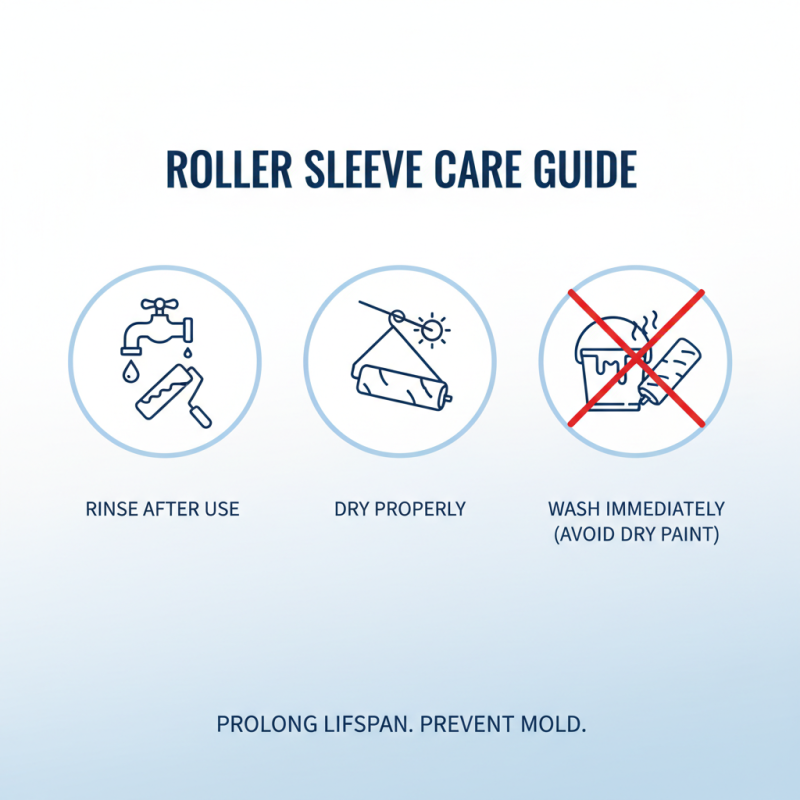

When it comes to roller sleeves, maintenance is essential. Keeping your roller sleeves clean will prolong their lifespan. After each use, rinse them thoroughly. Drying them properly also prevents mold growth. If paint dries on the sleeve, it becomes challenging to clean. Avoid that by washing immediately.

Store roller sleeves in a cool, dry place. A loose plastic bag can help keep them from dust. However, don't seal them tightly—air circulation is important. If they seem worn or frayed, it might be time for a replacement. A damaged sleeve can ruin your perfect finish.

Think about the material, too. Different paints require different sleeves. Some fibers absorb paint better, while others apply it evenly. Experiment to find what works for your projects. It's normal to have a few trials and errors along the way. Learning from these helps improve your skills.