Choosing the right Textile Machine Roller Sleeve is crucial for optimal performance. This component plays a vital role in textile machinery, impacting production efficiency. A suitable sleeve can enhance fabric quality and reduce downtime.

When selecting a Textile Machine Roller Sleeve, consider its material and size. Different textiles require specific properties. For instance, some sleeves work better with lighter fabrics, while others handle heavier materials. A mismatch can lead to complications. Furthermore, the sleeve's maintenance is critical. Neglecting proper care can shorten its lifespan, leading to more costs later.

It’s easy to overlook these details, yet they matter significantly. Some users may rush this decision, leading to future issues. Reflecting on this can provide insight. Overall, the right choice improves overall production and efficiency.

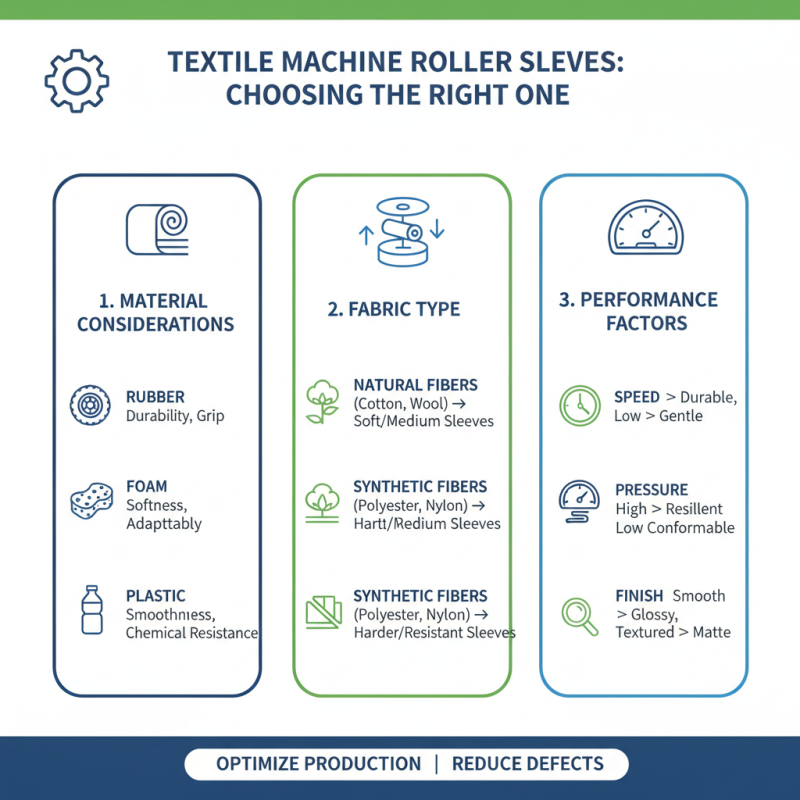

Choosing the right textile machine roller sleeve can be challenging. Many factors play a role in this decision. Start by considering the material of the roller sleeve. Different fabrics require different types of sleeves. Some are made from rubber, while others use foam or plastic. Each material has unique properties that affect performance.

Look at the diameter and length of the sleeve. It needs to match your machinery specifications. A sleeve that is too large or too small can cause issues. Pay attention to the thickness as well. Thicker sleeves may offer durability but can be harder to manage. You might find that a thinner option provides better control in certain applications.

Another aspect to consider is the texture. Some sleeves are smooth, while others have patterns. The choice affects how the fabric interacts with the machine. This decision may seem small, yet it can impact overall efficiency. Be mindful that every machine and fabric combination is unique. Testing different options may lead to surprising results. Don’t hesitate to reflect on your choices as this can lead to better outcomes.

When selecting the right textile machine roller sleeve, understanding the materials is critical. Roller sleeves are commonly made from polyurethane, rubber, or felt. Each material serves different purposes and performances, impacting overall efficiency.

Polyurethane sleeves are known for their durability and resistance to wear. Reports indicate they can last up to 30% longer than rubber options. However, they can be more expensive upfront. Rubber sleeves are more affordable but may wear out sooner. This raises questions about long-term cost-effectiveness.

Tip: Consider your production needs carefully. If you prioritize longevity and high performance, polyurethane might be the best fit despite the higher price.

Felt sleeves offer unique benefits, particularly in dyeing processes. They provide excellent absorbency, but wear out faster compared to synthetic materials. Choosing felt might present challenges in high-volume operations. Striking a balance between performance and cost is vital.

Tip: Ensure to review supplier specifications. This can reveal potential issues with compatibility and performance limits. Always assess how the roller sleeve interacts with your specific machinery. Never overlook the material's implications on the final product quality.

When selecting a textile machine roller sleeve, dimensions play a crucial role. The diameter influences the fabric’s tension and handling. For instance, a larger diameter can reduce wrinkles but may also limit flexibility. It's essential to find a middle ground that suits your specific application.

Length is equally important. A sleeve that is too short may not provide adequate coverage. This can lead to uneven tension across the fabric. On the flip side, an overly long sleeve might complicate the installation process and affect performance. Experimenting with different lengths can yield surprising results, sometimes leading to unexpected issues.

Material composition also affects performance. Certain materials may wear down faster or react differently under heat. Testing various sleeve materials can reveal performance discrepancies that aren't immediately obvious. Sometimes, it's these subtle differences that can impact productivity. Continuous testing and reflection on these aspects can improve output and ensure optimal machine performance.

When selecting roller sleeves for textile machines, cost-effectiveness is a crucial factor. In recent studies, it has been noted that improper selection can lead to a waste of resources. For instance, companies report that the wrong roller sleeve can result in a waste of up to 20% in material usage. This increased cost adversely affects overall profitability.

Return on investment (ROI) is another key aspect. Data shows that investing in higher-quality roller sleeves can yield a 15% increase in production efficiency. A well-chosen roller sleeve not only extends the machine's lifespan but can also reduce downtime. For example, investing in a durable sleeve may require a higher initial outlay but usually pays off within the first six months of use.

However, it is essential to consider the balance between cost and quality. A focus solely on lower costs could lead to poor performance and increased maintenance costs. Reports indicate that companies often face higher operational costs when choosing cheaper options. Weighing these factors is vital for long-term success in the textile industry.

| Dimension | Type A (Economical) | Type B (Standard) | Type C (Premium) |

|---|---|---|---|

| Initial Cost ($) | 500 | 800 | 1200 |

| Average Lifespan (years) | 2 | 4 | 6 |

| Maintenance Cost ($/year) | 100 | 75 | 50 |

| Estimated Production Increase (%) | 5 | 10 | 15 |

| ROI (%) | 10 | 15 | 20 |

The textile industry is undergoing rapid advancements in roller sleeve technology. New materials are enhancing durability and efficiency. Reports indicate that up to 30% of production time can be saved with improved roller sleeves. Innovations in coatings and surface treatments are reducing stickiness, allowing smoother operations. This trend is creating a shift towards more eco-friendly materials, aligning with sustainability goals.

Tip: Always assess the material compatibility before selecting a roller sleeve. This ensures optimal performance and reduces wear.

Moreover, the introduction of smart textiles is redefining what roller sleeves can achieve. Sensors integrated into the sleeves monitor performance in real-time. This data can help in predictive maintenance, potentially cutting downtime by 20%. However, the complexity of these systems may present integration challenges.

Tip: Look for training resources on new technologies. Understanding these advancements can enhance your operational effectiveness.