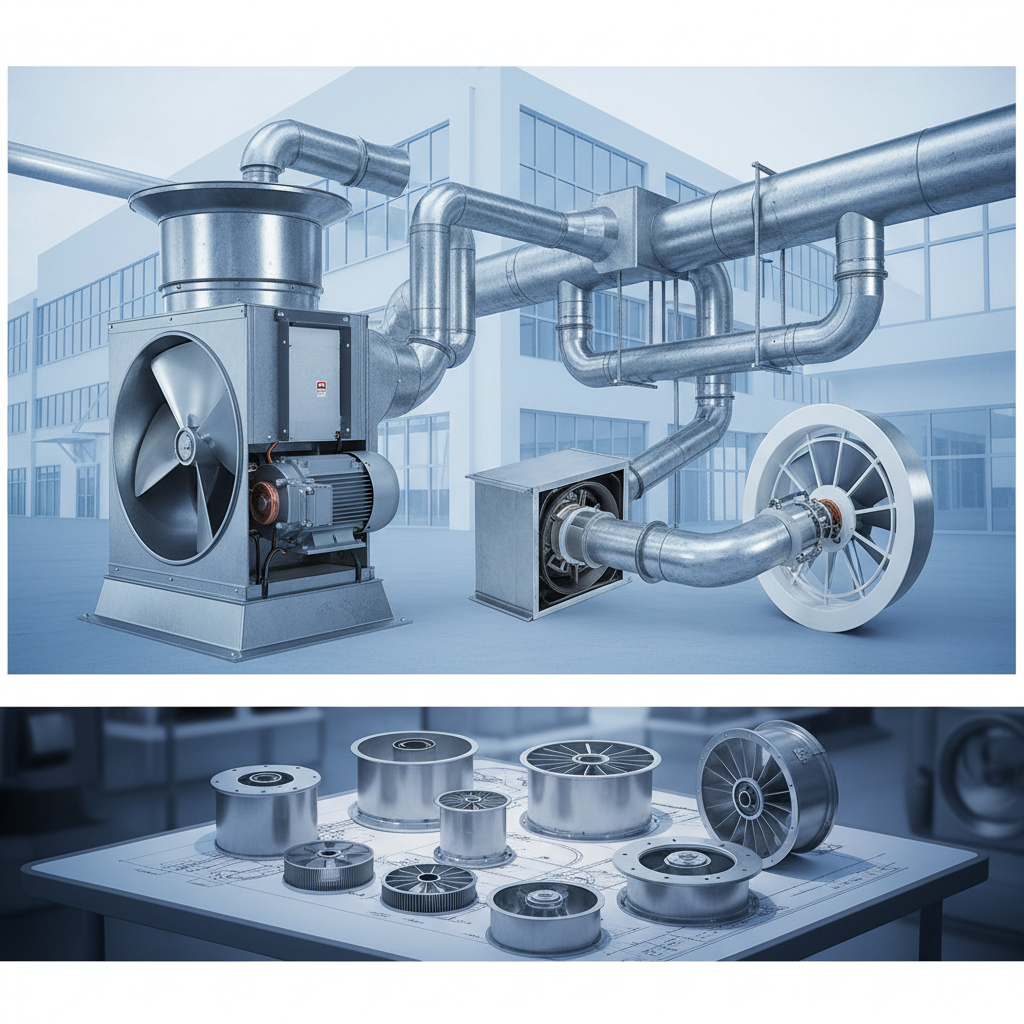

In the ever-evolving landscape of industrial ventilation, the selection of the right equipment is crucial for ensuring operational efficiency and air quality. Centrifugal Ventilation Fans play a pivotal role in a variety of applications, from HVAC systems to manufacturing plants. According to a report by MarketsandMarkets, the global industrial fan market is projected to reach $8.3 billion by 2026, with centrifugal fans witnessing significant demand due to their superior performance in handling larger volumes of air at varying pressures.

Choosing the best Centrifugal Ventilation Fans requires a comprehensive understanding of specific operational needs, including airflow requirements, pressure differentials, and energy efficiency. The U.S. Department of Energy reported that properly selected and maintained fans can save up to 25% in energy costs, emphasizing the importance of aligning fan specifications with application demands. Thus, this guide aims to equip you with essential criteria and expert insights to help you navigate the myriad of options available in the market and make an informed decision that aligns with your operational goals.

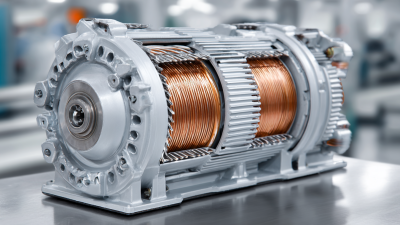

In 2025, understanding the various types of centrifugal ventilation fans is essential for making informed decisions that meet specific requirements. Centrifugal fans are engineered to provide efficient airflow, and they come in several configurations, including backward-curved, forward-curved, and radial blades. Each design has its unique operational characteristics and is suited for different applications.

According to the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), backward-curved fans are highly efficient and ideal for applications requiring high pressure, making them popular in commercial HVAC systems.

Moreover, the market's demand for energy-efficient ventilation solutions continues to rise. A recent report from MarketsandMarkets suggests that the global centrifugal fan market is projected to reach USD 7.8 billion by 2025, reflecting a compound annual growth rate (CAGR) of 4.2%. This growth is driven by increased industrial activities and the need for better air quality in various sectors. As consumers become more eco-conscious, selecting the right fan not only impacts performance but can also contribute significantly to energy savings. Thus, understanding the types and specifications of centrifugal ventilation fans is crucial for optimizing environmental and economic performance in various settings.

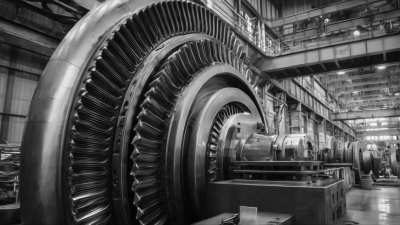

Selecting the best centrifugal ventilation fans for your specific requirements hinges on understanding key performance metrics such as CFM (Cubic Feet per Minute), static pressure, and efficiency. CFM measures the volume of air a fan can move, making it essential for ensuring adequate ventilation in a given space. According to the Air Movement and Control Association (AMCA), the desired CFM rating often depends on the characteristics of the application, with standards suggesting that well-ventilated areas typically require airflow rates between 400 – 600 CFM per occupant in commercial settings.

Static pressure is another critical factor that influences fan selection. It refers to the resistance airflow must overcome, which is especially important in ducted systems. A report by the National Fan Institute indicates that fans designed to operate at higher static pressures are essential in applications with complex ductwork or when overcoming obstructions. Balancing CFM and static pressure is crucial for achieving optimal airflow without overworking the fan, thus enhancing its efficiency and lifespan.

Efficiency, typically represented as the fan's energy consumption versus airflow produced, is increasingly significant as energy costs rise. The U.S. Department of Energy emphasizes selecting fans with high-efficiency ratings, as they can lead to energy savings of up to 30% over standard models. Understanding these metrics not only informs the selection process but also guarantees that the chosen fan meets the specific ventilation needs while operating sustainably and cost-effectively.

When selecting centrifugal ventilation fans, it's crucial to consider not only their efficiency but also their noise levels and acoustic performance. According to the American National Standards Institute (ANSI), the ideal sound levels for commercial ventilation systems should not exceed 50 dB in occupied spaces to ensure comfort for occupants. With noise pollution becoming a growing concern, the push for quieter fans has led to innovations in fan design, such as the implementation of sound-absorbing materials and optimized blade shapes that can reduce operational noise by up to 10 dB while maintaining airflow efficiency.

Additionally, a report from the Global Ventilation Equipment Market indicates that the market for low-noise ventilation solutions is expected to grow by over 25% by 2025. This trend underscores an increasing demand for products that align with both environmental and acoustic regulations. When choosing a centrifugal fan, stakeholders must balance between achieving optimal airflow and minimizing sound levels, ensuring that the selected equipment meets both performance criteria and complies with noise control standards. The right choice can significantly enhance indoor environmental quality, making it essential to prioritize both efficiency and quiet operation in the decision-making process.

When selecting the best centrifugal ventilation fans, understanding energy efficiency ratings and regulations is crucial in guiding your choices towards sustainable solutions. Industry standards, such as those set by the U.S. Department of Energy (DOE) and other organizations, provide essential benchmarks—models with high-efficiency ratings can reduce energy consumption by up to 50%. Additionally, the use of Energy Star-rated products is becoming increasingly popular, as they not only meet strict energy efficiency guidelines but can also significantly lower operating costs over their lifespan.

Tip: Always check the fan's efficiency rating before making a purchase. Look for fans that comply with the latest regulations and have certifications to ensure they meet or exceed energy efficiency standards.

Moreover, it's important to stay updated on regional regulations, as different areas may have unique requirements regarding ventilation systems. Adopting innovations like variable speed drives can further enhance efficiency. According to the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), optimizing fan speed can lead to a marked reduction in energy usage while maintaining indoor air quality.

Tip: Regularly review your ventilation system’s performance to ensure compliance with local regulations and identify opportunities for energy savings.

| Model | Airflow (CFM) | Power Consumption (Watts) | Energy Efficiency Ratio (EER) | Noise Level (dB) | Regulatory Compliance |

|---|---|---|---|---|---|

| Model A | 800 | 120 | 6.67 | 50 | ENERGY STAR |

| Model B | 1000 | 150 | 6.67 | 55 | AHRI Certified |

| Model C | 600 | 90 | 6.67 | 48 | ECBC Compliant |

| Model D | 750 | 110 | 6.82 | 52 | UL Listed |

| Model E | 900 | 140 | 6.43 | 58 | ISO 9001 |

When selecting centrifugal ventilation fans in 2025, a cost-benefit analysis is crucial to assess the long-term value of different models available in the market. According to the latest report by the Global Ventilation Fan Association (GVFA), the operational efficiency of centrifugal fans has improved significantly over the past few years, with energy savings of up to 30% for new models compared to those manufactured a decade ago. This reduction in energy consumption not only decreases utility costs but also contributes to a more sustainable operation, aligning with the growing emphasis on environmental responsibility in industry practices.

Moreover, initial investments in advanced centrifugal fan technology, such as EC (electronically commutated) motors and variable speed drives, can yield considerable returns over their lifespan. A study from the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) indicates that while cutting-edge fans may have a higher upfront cost, the total cost of ownership is significantly lower, with payback periods ranging from 1.5 to 3 years based on energy savings alone. Thus, businesses should carefully evaluate both the immediate costs and the long-term savings to make informed decisions that align with their operational goals and budget constraints.