In the ever-evolving landscape of mining and aggregate production, the role of the Crusher Hammer Head has never been more pivotal. With advancements in technology and material science, understanding the various types of hammer heads and their specific applications is crucial for maximizing efficiency and productivity in crushing operations. As we approach 2025, it is essential to explore the characteristics, benefits, and potential uses of these vital components.

This ultimate guide aims to shed light on the different designs of Crusher Hammer Heads, from their shapes and sizes to the materials used in their construction. Each variation serves a distinct purpose and offers unique advantages depending on the material being crushed and the specific conditions of the operation. By delving into the nuances of hammer head types, operators can make informed decisions that enhance performance while reducing wear and maintenance costs.

As we navigate through 2025, the insights presented in this guide will equip professionals in the industry with the knowledge needed to optimize their crushing systems. Embracing the innovations in Crusher Hammer Head technology will not only improve output but also encourage sustainable practices in material processing, positioning businesses for success in a competitive market.

When selecting hammer heads for crushers, understanding the material composition and characteristics is crucial for optimizing performance and extending service life. Typically, hammer heads are made from various materials, including high carbon steel, manganese steel, and alloy steel. According to a report by Global Mining Review, high carbon steel offers excellent wear resistance and is beneficial for crushing harder materials but might be less effective at impact. Manganese steel, often favored in the industry, provides durability and toughness; it enables the hammer to withstand heavy impacts while maintaining an edge in abrasion resistance. Its work-hardening nature significantly enhances performance, making it suitable for high-impact applications.

In addition to metallurgical properties, the design of hammer heads greatly influences their effectiveness in different crushing scenarios. Studies indicate that variations in design, such as the shape, weight distribution, and surface treatment, can lead to significant differences in performance efficiency. Research by the Mining and Materials Science Association reveals that optimizing these factors can improve the overall energy efficiency of crushing processes by up to 15%. Moreover, specific applications—ranging from minerals processing to recycling—demand tailored hammer designs to meet varying operational challenges, ensuring the ideal hammer head type is critical for maximizing productivity and reducing operational costs.

In the realm of material processing, the type of hammer head used in crushers can significantly influence the efficiency and effectiveness of crushing operations. Each hammer head type has unique characteristics that make it suitable for specific applications.

For instance, low-alloy steel hammer heads are commonly employed in the production of aggregates, where their resistance to wear and impact is crucial for processing abrasive materials. These hammer heads can withstand the rigorous demands of crushing rocks, ensuring a longer lifespan and reduced downtime due to maintenance.

On the other hand, tungsten carbide-tipped hammer heads are favored in recycling applications, particularly for breaking down tougher materials such as concrete and asphalt. Their superior hardness allows them to tackle demanding tasks with ease, providing enhanced performance while minimizing wear. Additionally, these hammer heads contribute to a clean and efficient breaking process, which is essential in recycling operations where material purity is critical.

Choosing the right hammer head type, therefore, is vital for optimizing crusher performance and achieving desired output specifications in various industries.

The performance metrics of crusher hammer heads in 2025 are primarily defined by two critical factors: efficiency and lifespan. Efficiency refers to the hammer head's ability to break down materials effectively while minimizing energy consumption. As industries increasingly focus on sustainable practices, the development of advanced materials and design innovations enhances the aerodynamic shape and weight distribution of hammer heads. This leads to improved impact force, allowing for better fragmentation of hard materials, thus maximizing productivity without a corresponding increase in energy expenditure.

Lifespan, on the other hand, is crucial for reducing operational costs and downtime. In 2025, improvements in metallurgy and heat treatment processes have resulted in hammer heads that are significantly more durable and resistant to wear and fatigue. The integration of advanced coatings and alloy compositions enhances their resistance to abrasive materials and operational stress, contributing to longer service intervals. Consequently, operators can achieve more extended periods of uninterrupted operation, which affords them greater reliability in production schedules and maintenance planning. By prioritizing both efficiency and lifespan, the crusher industry is poised to meet the demands of an evolving market while ensuring economic sustainability.

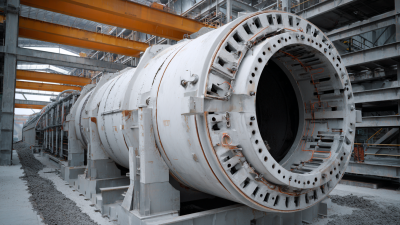

In 2025, the landscape of industrial crushing applications has evolved, leading to a diverse array of hammer head designs tailored for specific operational needs. Different industries ranging from mining to recycling have adopted various hammer head types that enhance productivity and efficiency. For instance, the geology of materials processed in the mining sector often necessitates the use of heavy-duty hammer heads designed for prolonged impact resistance. These hammers typically feature enhanced hardness and toughness, effectively reducing wear and extending lifespan, making them ideal for the grinding of hard rock types.

Conversely, industries focused on waste management and recycling might prioritize lighter, more versatile hammer head designs that allow for quick adjustments and replacements. Such hammer heads often incorporate innovative materials that balance weight and strength, ensuring they can efficiently handle a variety of substrates without compromising performance.

The comparative analysis of these hammer head designs reveals that industry-specific needs drive the customization of shape, size, and metallurgical composition, ultimately leading to enhanced operational outcomes tailored to different material characteristics and processing demands.

In 2025, the crusher hammer head technology is set to evolve significantly, driven by advancements in materials science and engineering. These innovations aim to enhance the efficiency and durability of hammer heads, allowing them to withstand greater impact forces while minimizing wear and tear. Research is focusing on the development of composite materials and specialized coatings that combine the robust properties of traditional metals with the lightweight characteristics of modern composites. This will not only improve performance but also reduce the overall weight of the hammer heads, leading to better energy efficiency in crushing processes.

Tips for optimizing the use of crusher hammer heads in 2025 include selecting the right material based on the specific application. For instance, high-chromium cast iron could be ideal for abrasive materials, while newer alloys may offer better toughness for high-impact operations. Additionally, it's crucial to monitor wear patterns closely to predict maintenance needs and avoid unexpected downtimes. Regularly upgrading to the latest hammer head designs could yield significant operational efficiencies and cost savings over time.

As the industry moves forward, automation and smart technologies are expected to play a pivotal role in the utilization of hammer heads. Implementing smart sensors that track performance metrics in real-time can provide invaluable insights for optimizing crushing operations. By combining these technological innovations with effective maintenance strategies, companies can achieve enhanced productivity and maximize their return on investment.