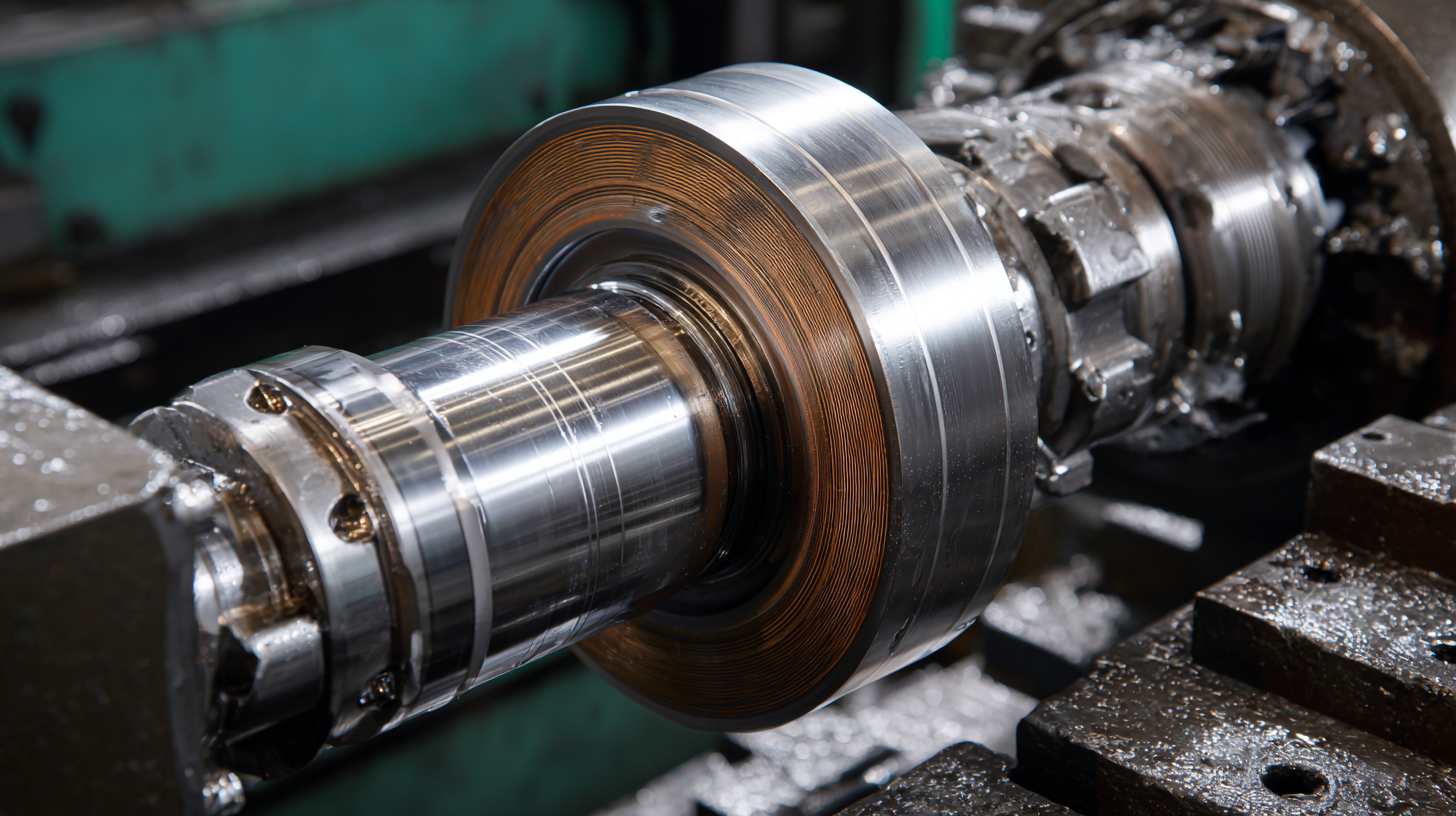

In the ever-evolving landscape of industrial manufacturing, enhancing efficiency is a paramount goal for operations seeking to optimize performance and reduce costs. One innovative solution that has gained traction in recent years is the implementation of Tungsten Carbide Roller Sleeves. These specialized components are designed to withstand the rigors of high-speed production environments, offering superior durability and performance compared to traditional materials. By integrating Tungsten Carbide Roller Sleeves into manufacturing processes, companies can significantly minimize downtime caused by wear and tear, enhance the quality of their products, and ultimately boost overall productivity.

This article explores the myriad benefits of utilizing Tungsten Carbide Roller Sleeves in industrial operations, providing practical insights on how to enhance manufacturing efficiency and position your business for success in a competitive market.

Tungsten carbide roller sleeves are quickly becoming a vital component in industrial operations, thanks to their remarkable durability and performance. These sleeves are engineered to withstand extreme conditions, including high temperatures and abrasive materials. By incorporating tungsten carbide roller sleeves into manufacturing processes, companies can experience enhanced operational durability, leading to reduced downtime and maintenance costs.

Tungsten carbide roller sleeves are quickly becoming a vital component in industrial operations, thanks to their remarkable durability and performance. These sleeves are engineered to withstand extreme conditions, including high temperatures and abrasive materials. By incorporating tungsten carbide roller sleeves into manufacturing processes, companies can experience enhanced operational durability, leading to reduced downtime and maintenance costs.

Tip: When selecting tungsten carbide roller sleeves, consider factors such as load requirements and environmental conditions to ensure optimal performance and longevity. Regular inspections can further enhance the lifespan of these sleeves, ensuring they remain effective throughout their use.

The benefits of tungsten carbide roller sleeves extend beyond mere durability. Their resistance to wear and tear significantly improves production efficiency by maintaining consistent operational quality. This ultimately boosts productivity and minimizes the frequency of equipment failure, allowing manufacturers to meet demand reliably and effectively.

Tip: Implement preventative maintenance schedules that include monitoring the condition of roller sleeves. Early detection of wear can prevent unexpected breakdowns and enhance overall operational efficiency.

In the quest for enhanced manufacturing efficiency, assessing key performance metrics of tungsten carbide roller sleeves is critical. Recent industry reports indicate that adopting tungsten carbide materials can lead to increased durability of roller sleeves by up to 300% compared to traditional steel. This remarkable longevity reduces the frequency of replacements, thereby minimizing downtime in production lines and ultimately improving overall operational efficiency.

Moreover, tungsten carbide roller sleeves demonstrate superior wear resistance, with studies showing a decrease in wear rates by approximately 50% under standard operational conditions. This wear reduction translates to consistent product quality and reduced maintenance costs, as machinery operates effectively without significant degradation over time. By focusing on these performance metrics, manufacturers can not only achieve a more streamlined production process but also maximize their return on investment, highlighting the indispensable role of advanced materials in modern industrial operations.

This chart displays the key performance metrics evaluating the efficiency of tungsten carbide roller sleeves in manufacturing operations over a six-month period.

The financial impact of using tungsten carbide roller sleeves in industrial operations is increasingly evident, especially when compared to traditional materials. A recent report by the International Journal of Manufacturing Science indicates that tungsten carbide can extend the lifespan of roller sleeves by up to 50%, reducing the frequency of replacements and downtime associated with maintenance. This longevity directly translates to cost savings, as manufacturers can allocate resources more efficiently and minimize production interruptions.

Moreover, the initial investment in tungsten carbide roller sleeves is often recouped within the first year of operation. Industry assessments suggest that companies transitioning from conventional steel rollers to tungsten carbide may experience a reduction in overall operational costs by approximately 20-30%. This reduction includes savings from decreased wear and tear, lower maintenance costs, and increased production capacity due to enhanced efficiency. Ultimately, the use of tungsten carbide not only improves performance but also positions manufacturers to enhance their bottom line significantly, making it a compelling choice for modern industrial applications.

Integrating tungsten carbide roller sleeves into production line workflows can significantly enhance manufacturing efficiency. According to industry studies, the application of tungsten carbide, which is known for its hardness and wear resistance, can lead to a decrease in machine downtime by up to 30%. This reduction in downtime not only optimizes production schedules but also allows companies to meet increasing demands without the need for additional machinery or labor.

Furthermore, incorporating tungsten carbide sleeves into the production process has been shown to improve the accuracy and consistency of product outputs. A report by the Metal Processing Institute highlights that using tungsten carbide components can increase the lifespan of machinery by as much as 50%, contributing to reduced maintenance costs and minimizing disruptions. By strategically placing these sleeves in high-friction areas of the production line, manufacturers can achieve smoother operations, ultimately leading to a significant boost in overall productivity and cost efficiency.

In recent years, various industries have turned to tungsten carbide roller sleeves to enhance manufacturing efficiency. A notable example can be found in the automotive sector, where companies like Ford have reported improvements in production rates by over 20% after integrating these robust sleeves into their assembly lines. According to a report by the Manufacturing Institute, incorporating advanced materials such as tungsten carbide can lead to a 30% reduction in wear rates, significantly prolonging the lifespan of machinery components.

The food processing industry has also witnessed the benefits of tungsten carbide roller sleeves. A case study conducted by the Food Processing Suppliers Association revealed that a leading dairy manufacturer decreased downtime by 15% after replacing standard roller sleeves with tungsten carbide alternatives. The enhanced durability and resistance to wear and tear in harsh environments have made these sleeves a preferred choice, thereby streamlining operations and reducing maintenance costs significantly. Such real-world implementations illustrate the positive impact of tungsten carbide technology across various sectors, highlighting its role in driving efficiency and profitability in industrial operations.

| Industry | Application | Efficiency Improvement (%) | Reduction in Downtime (%) | Cost Savings ($) |

|---|---|---|---|---|

| Automotive | Precision Machining | 25% | 30% | $50,000 |

| Food Processing | Conveyor Systems | 20% | 25% | $30,000 |

| Textiles | Spinning Machines | 30% | 35% | $20,000 |

| Packaging | Filling Machines | 15% | 20% | $10,000 |

| Aerospace | Component Assembly | 28% | 40% | $70,000 |