Choosing the right roller sleeve is a crucial step in ensuring your painting projects are executed with precision and ease. With a variety of options available, selecting the appropriate roller sleeve can significantly affect the finish and quality of your work. Whether you're tackling a small home improvement or a larger renovation, understanding the distinct features of roller sleeves is essential for achieving the desired results.

Roller sleeves come in different materials, nap lengths, and sizes, each serving specific purposes that influence paint application. The right roller sleeve can enhance your project by providing even coverage, minimizing drips, and reducing the amount of time spent on touch-ups. As you embark on your next painting endeavor, it’s important to consider how the characteristics of roller sleeves align with the type of paint you're using and the surface you're painting. This guide will explore ten essential tips that will aid you in making an informed choice, optimizing your painting efforts while ensuring a professional-looking finish.

When it comes to selecting the right roller sleeve for your painting projects, understanding the various types available is crucial. Roller sleeves come in different materials and nap lengths, each designed to tackle specific surfaces and paint types. For instance, synthetic fibers are commonly used for water-based paints, providing a smooth finish on flat surfaces, while natural fibers work well with oil-based products, ensuring good paint pickup and release.

Moreover, the nap length of a roller sleeve significantly affects the final texture of the paint application. Short naps, typically around ¼ inch, are ideal for smooth surfaces such as drywall, allowing for a sleek finish. In contrast, a medium nap (½ inch to ¾ inch) can handle semi-smooth surfaces, and a long nap (1 inch or more) is perfect for textured surfaces, helping to fill in grooves and imperfections effectively. By matching the roller sleeve type and nap length to your specific painting needs, you can achieve better results and save time during your projects.

When it comes to selecting the right roller sleeve for your painting projects, understanding the fabric materials is crucial for achieving optimal paint application. Roller sleeves come in various materials, each designed to cater to specific types of surfaces and paint types. For instance, natural fabrics such as lambswool or mohair are excellent choices for rough surfaces, as they provide excellent paint pickup and release due to their high nap. These materials help to ensure an even coat, especially on textured walls, while allowing for better coverage in just a few strokes.

On the other hand, synthetic fabrics like polyester or nylon are often preferred for smooth surfaces, as they create a fine finish and contribute to a more controlled application of paint. These materials are typically less absorbent, which can be advantageous when working with water-based paints or when a thinner coat is desired. It’s essential to consider both the surface you’re working on and the type of paint you’ll be using when selecting a roller sleeve, as the right fabric can significantly impact the overall quality and durability of your paint job. By evaluating these factors, you ensure that your painting efforts yield the best possible results, making your projects not only easier but also more successful.

When selecting the right roller sleeve for your painting projects, one of the key considerations is the size and nap length of the roller. The size of the roller sleeve affects how much paint it can hold and how quickly you can cover large areas. For smaller projects or detailed work, a narrow roller (around 4-6 inches) is often sufficient, while larger areas benefit from wider rollers (9-18 inches). Choosing the right width helps ensure efficiency and an even finish.

The nap length, which refers to the thickness of the fibers on the roller, plays a crucial role in achieving the desired texture. Short nap rollers (1/4 to 3/8 inch) are best for smooth surfaces like drywall, providing a fine finish. In contrast, longer nap rollers (1/2 inch to 1 inch) are ideal for textured surfaces as they can reach into grooves and crevices, making it easier to apply paint evenly.

Tip: Always consider the type of paint you are using, as different finishes may require different nap lengths for optimal results. Another important tip is to use a roller sleeve that matches the paint type; for example, use a synthetic roller for water-based paints and a natural fiber roller for oil-based paints to enhance performance and coverage.

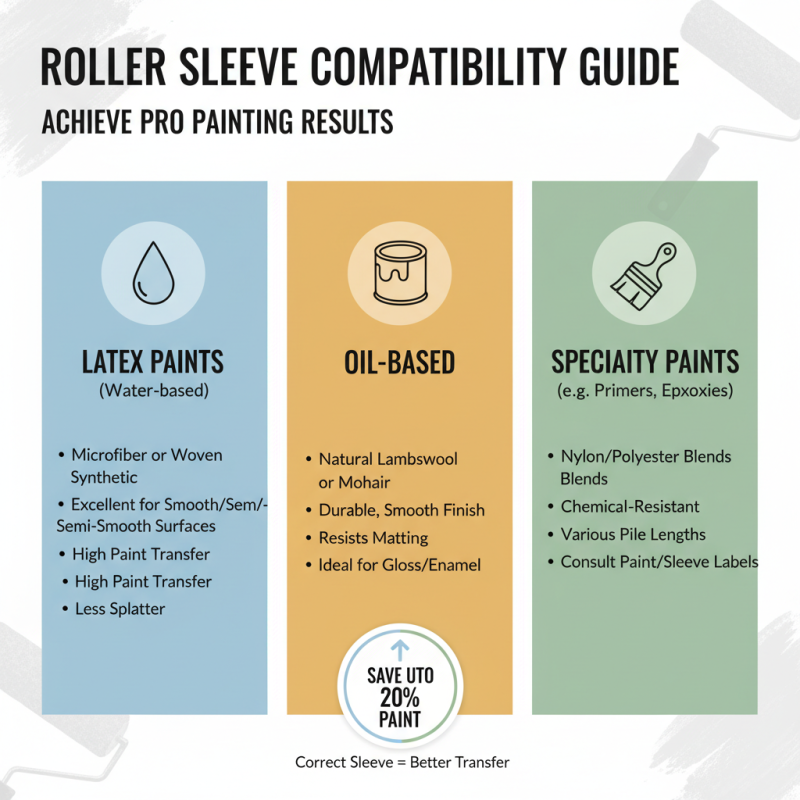

Choosing the right roller sleeve is crucial for achieving professional results in your painting projects, and one of the most important factors to consider is the compatibility of the roller sleeve with various paint types. Different paint formulations, including latex, oil-based, and even specialty paints, require specific roller sleeves to ensure optimal application and finish quality. For example, a report by the Paint Quality Institute indicates that using the correct roller sleeve can improve paint transfer and reduce the amount of paint needed by up to 20%, resulting in significant cost savings for both DIY enthusiasts and professional painters.

When assessing compatibility, consider the material and nap length of the roller sleeve. Natural fibers, like lambswool, are ideal for oil-based paints, as they are better at holding and distributing thicker paints. In contrast, synthetic materials, such as microfiber or polyester, work effectively with latex paints due to their ability to create a smooth finish while minimizing lint. Furthermore, the nap length affects the texture: a longer nap is suitable for rough surfaces, while a shorter nap ensures a fine finish on smooth surfaces. According to a study by the National Association of Home Builders, using the correct sleeve type can enhance coverage and reduce application time by over 30%, highlighting the importance of making informed choices based on paint type and surface characteristics.

When it comes to maintaining roller sleeves for your painting projects, proper care can significantly prolong their lifespan. After each use, it is crucial to clean the roller sleeves thoroughly. Begin by rinsing them under warm water to remove excess paint, followed by using a mild detergent to eliminate any remaining residues. For tougher paints, consider using a fabric cleaner specifically designed for roller sleeves. Always reshape the fibers after cleaning to ensure they maintain their original texture, which is vital for achieving a smooth finish in subsequent jobs.

Storage is another key aspect of maintaining roller sleeves. After cleaning and drying, store the sleeves in a cool, dry place, avoiding areas where they might be exposed to extreme temperature changes or moisture. Consider using a dedicated container to keep them free from dust and debris, which can disrupt the painting process when reused. Additionally, keeping roller sleeves flat can help prevent deformation of the fibers, further contributing to their longevity. By following these simple maintenance tips, you can ensure that your roller sleeves remain in top condition for your future painting endeavors.

| Tip | Description | Benefits |

|---|---|---|

| 1. Choose the Right Nap | Select roller sleeves with an appropriate nap length for your surface type. | Ensures even application of paint. |

| 2. Consider Material | Use synthetic fibers for water-based paints and natural fibers for oil-based paints. | Increases paint adhesion and finish quality. |

| 3. Size Matters | Choose the sleeve size based on the area you are painting. | Affects efficiency and control during painting. |

| 4. Quality Over Price | Invest in high-quality roller sleeves for the best results. | Provides better coverage and durability. |

| 5. Cleanliness is Key | Keep roller sleeves clean post-use to prolong their life. | Reduces material waste and maintains performance. |

| 6. Test Before Use | Conduct a test stroke with your roller sleeve on a sample area first. | Helps gauge the finish and performance. |

| 7. Store Properly | Store roller sleeves in a dry, cool place away from direct sunlight. | Prevents damage and degradation of materials. |

| 8. Rotate Your Sleeves | Use different sleeves for various tasks to avoid wear and tear. | Extends the lifespan of each roller sleeve. |

| 9. Avoid Overloading | Don’t overload the roller with too much paint. | Prevents drips and excessive wear. |

| 10. Dispose Properly | Follow local regulations for disposing of used roller sleeves. | Ensures environmental compliance and responsibility. |