Understanding Permanent Magnet Synchronous Motors (PMSMs) can be a challenge. John Doe, a renowned expert in the field, emphasizes, "PMSMs are the future of efficient motor technology." The growing interest in these motors highlights their importance in various applications. However, not all aspects of PMSMs are straightforward.

Many engineers struggle with the control mechanisms of PMSMs. This complexity can lead to inefficiencies if not addressed properly. Moreover, the integration of advanced electronics can further complicate the understanding of these motors. Each system has its own quirks, and often, details are overlooked during implementation.

Exploring the intricacies of Permanent Magnet Synchronous Motors reveals potential pitfalls. Many users fail to recognize the nuances in their behavior under different loads. Thus, it is vital to grasp both the strengths and limitations of PMSMs. Awareness of these factors enables better design choices and enhances overall performance in practical applications.

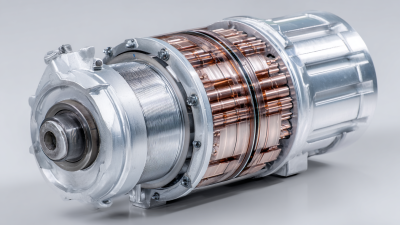

Permanent Magnet Synchronous Motors (PMSMs) are gaining popularity in various applications. They offer high efficiency and precise control. Understanding their basics is crucial for effective utilization. PMSMs operate using permanent magnets, which create a consistent magnetic field. This allows for smoother operation and less noise.

When working with PMSMs, pay attention to their torque characteristics. The torque is directly related to the magnetic strength of the magnets. A stronger magnet usually means more torque, but that’s not always the case. Considerations around the size and placement of these magnets greatly impact performance.

Another aspect to reflect on is the complexity of these motors' control systems. Advanced algorithms are required to achieve optimum performance. Simple setups may lead to inefficiencies or malfunction. Be prepared for trial and error when configuring motor settings. It's a learning process that can reveal important insights.

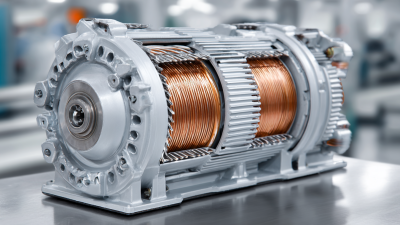

Permanent Magnet Synchronous Motors (PMSMs) are becoming increasingly popular in industrial applications. Their efficiency is impressive, boasting a typical operational efficiency of over 90%. This high efficiency results in reduced energy consumption and lower operational costs. For manufacturers, this means a significant return on investment in the long run, especially as energy prices continue to rise.

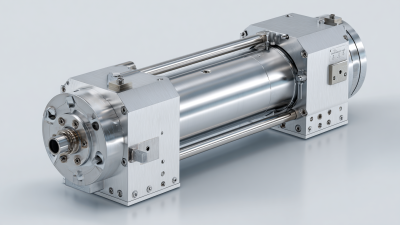

Incorporating PMSMs can lead to better performance in various industrial settings. These motors have a compact design, making them suitable for limited spaces. They also operate quietly, which improves workplace safety and comfort. Despite these advantages, some users find it challenging to implement PMSMs into existing systems. The initial setup can seem complex, leading to hesitations. Understanding the integration process is crucial for maximizing their benefits.

Tip: Always analyze the load requirements before selection. This ensures the motor operates at optimum performance. Another important aspect is to consider cooling systems, which can affect reliability. Monitoring and maintenance are crucial, yet some tend to overlook this stage. Regular checks can prevent unexpected failures and downtime. Investing time in understanding these aspects can help businesses leverage the full potential of PMSMs.

Permanent Magnet Synchronous Motors (PMSMs) are renowned for their efficiency and high performance. Understanding their technical specifications is crucial. Key metrics include torque, speed, and power factor. The torque produced is directly proportional to the current supplied. This relationship can be complex, requiring careful consideration during design.

Performance metrics are essential for evaluating a PMSM's operation. The efficiency of PMSMs typically ranges from 85% to 95%. These figures vary based on load and operational conditions. Additionally, temperature can affect performance. It's imperative to monitor heat generation within these systems as overheating can lead to failure.

Another vital aspect is the motor's speed control capabilities. PMSMs can operate at high speeds with great precision. However, achieving this requires sophisticated control techniques. Understanding these intricacies is key for effective application. Improper control can lead to inefficiencies, diminishing the motor's advantages. Balancing the technical specifications with real-world demands is a challenge worth exploring.

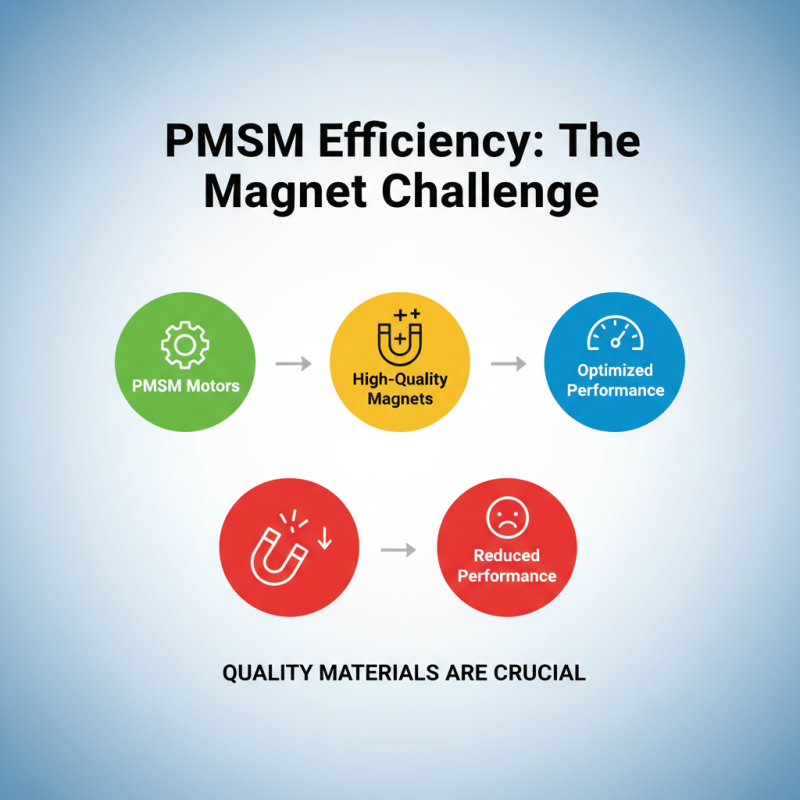

Permanent magnet synchronous motors (PMSMs) have gained popularity for their efficiency. However, they come with challenges that must be addressed. One common limitation is their dependence on high-quality magnets. If the quality of the magnets decreases, the motor's performance can suffer significantly. It's essential to ensure that superior materials are used during manufacturing.

Another challenge lies in their cost. PMSMs can be more expensive compared to different motor types. The initial investment may deter some manufacturers from considering them. Efficient design planning can help mitigate this issue.

To overcome these challenges, here are some tips. Assess your needs carefully. Determine if the benefits of a PMSM outweigh its costs. Regular maintenance is crucial. Ensuring components are in good condition can extend the motor’s life. Additionally, understanding the temperature limits of the magnets can prevent demagnetization.

Incorporating these tips can help you make better decisions. Evaluate your environment and how it affects motor performance. Address the limitations proactively to maximize benefits.

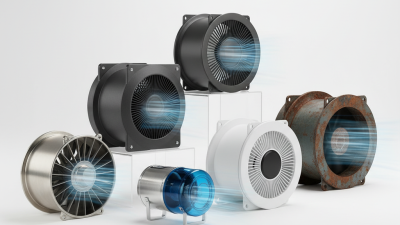

The landscape of permanent magnet motor technology is evolving rapidly. Innovations are making these motors more efficient. Enhanced materials are key. Advanced magnets with higher energy density are on the rise. This leads to smaller, lighter motors that perform better than older designs.

Tip: Pay attention to motor design. Improved cooling systems can boost performance. They are essential for high-power applications. It’s worth studying different designs to understand their benefits. Another point to reflect on is the impact of digital technologies. Smart motors equipped with sensors are gaining traction. They optimize performance in real-time, which adds complexity.

Future trends also include sustainable practices. Recyclable materials are becoming popular. This shift is necessary for environmental responsibility. However, challenges remain. The sourcing of rare earth elements for magnets continues to raise concerns. Balancing innovation with ethical production is crucial. Exploring alternative materials may be a good step forward. This dynamic field shows potential, but it requires careful deliberation.

This chart illustrates essential metrics of Permanent Magnet Synchronous Motors (PMSMs). The data represents typical values for efficiency, torque, speed, cost, and weight, showcasing the key aspects that impact their performance and adoption in various applications.