Understanding the performance and applications of PM synchronous motors is crucial for engineers and technicians working in various industries. These motors, distinguished by their use of permanent magnets, offer unique advantages such as high efficiency, compactness, and reliable operation. As the demand for advanced motor technology grows, having a thorough understanding of PM synchronous motor dynamics becomes increasingly important. This article presents ten essential tips to help you navigate the complexities of PM synchronous motor performance, from fundamental operational principles to practical application insights.

Whether you're involved in automation, robotics, or electric vehicle design, a solid grasp of PM synchronous motors will enable you to make informed decisions that enhance system performance and efficiency. By delving into the key factors influencing motor behavior—such as torque generation, speed control, and power ratings—engineers can optimize designs to meet specific operational requirements. The following sections will explore various aspects of PM synchronous motors, ensuring that readers gain valuable knowledge to effectively implement these advanced technologies in their projects.

Permanent Magnet (PM) synchronous motors are increasingly recognized for their efficiency and performance in a variety of applications. Fundamentally, these motors utilize permanent magnets embedded within their rotor structure, providing a constant magnetic field that interacts with the stator's rotating magnetic field. This design enables PM synchronous motors to achieve high torque and efficiency levels, often exceeding 90%, as reported by the International Electrotechnical Commission (IEC). Moreover, their ability to maintain synchronous speed under different loading conditions makes them ideal for applications requiring precision, such as industrial automation and robotics.

Understanding the performance characteristics of PM synchronous motors is crucial for maximizing their usefulness in modern industries. For instance, their power factor is typically higher than that of induction motors, largely due to the reduced slip in PM motors. According to a report by the U.S. Department of Energy, PM machines can save up to 30% in energy consumption compared to traditional induction motors when deployed in high-demand applications. Additionally, their compact design contributes to cost savings in terms of materials and installation space, which are often cited as critical factors in selecting motor types for new projects. As industries continue to prioritize efficiency and sustainability, PM synchronous motors stand out as a leading choice in advanced motor technology.

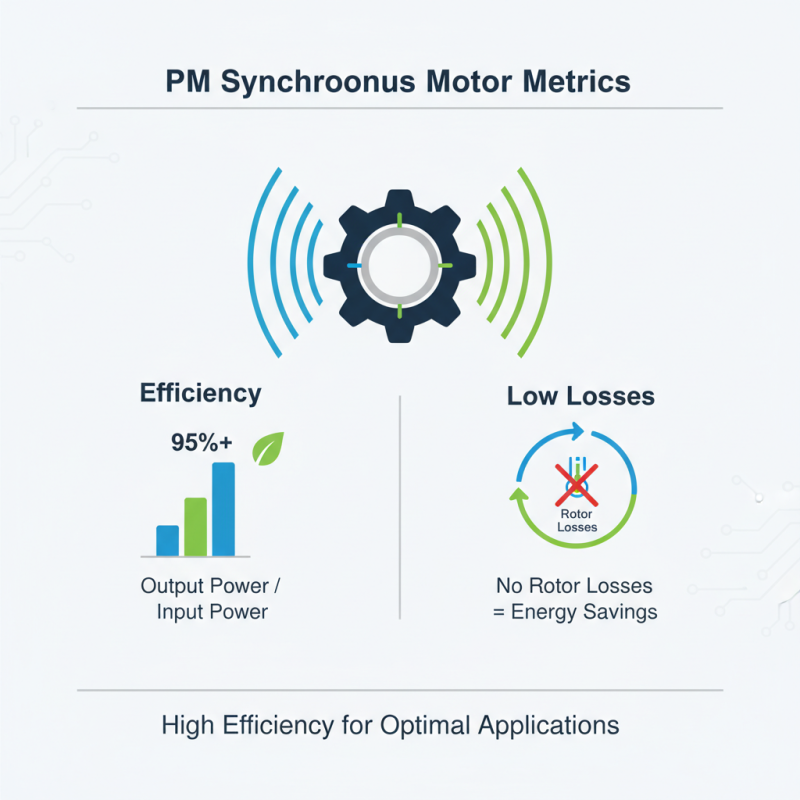

This bar chart illustrates key performance metrics of Permanent Magnet Synchronous Motors (PM Synchronous Motors), highlighting their efficiency, torque, speed, and power factor. These metrics are essential for understanding the motor's capabilities and applications in various industries.

Understanding the key performance metrics of Permanent Magnet (PM) Synchronous Motors is essential for optimizing their applications. One of the most critical metrics is the motor's efficiency, which directly impacts operational costs. Efficiency is typically quantified as the ratio of output power to input power, and for PM synchronous motors, efficiency levels can reach upwards of 95%. This high efficiency is primarily due to the design and the absence of rotor losses, making these motors ideal for applications requiring minimal energy waste.

Another important performance metric is torque characteristics, which determines how much load a motor can handle at various speeds. PM synchronous motors exhibit constant torque over a wide speed range, making them versatile for different industrial applications. The torque-to-weight ratio is also noteworthy; since these motors use permanent magnets, they can achieve high torque in a compact form. Additionally, considering factors like power factor and thermal performance can further enhance the understanding of how these motors will operate under specific conditions. By carefully analyzing these performance metrics, engineers can select and implement PM synchronous motors that best suit their intended applications.

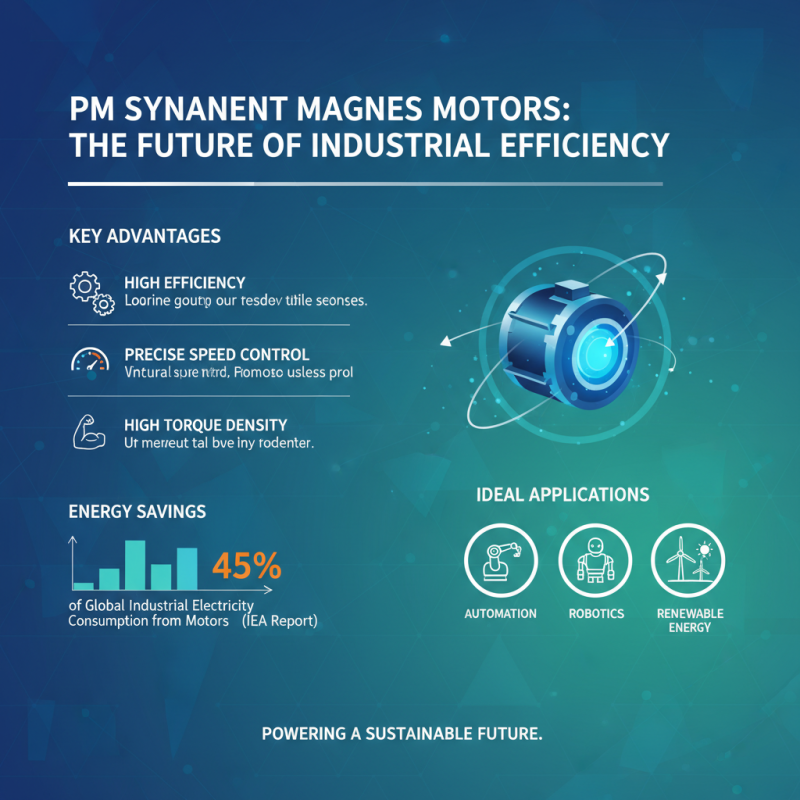

Permanent magnet (PM) synchronous motors have gained significant traction in various industrial applications due to their high efficiency and precise speed control. According to a report from the International Energy Agency, electric motors account for approximately 45% of global electricity consumption in industrial sectors, highlighting the importance of selecting efficient motor types. PM synchronous motors offer advantages such as high torque density and reduced energy losses, making them ideal for applications in automation, robotics, and renewable energy systems.

One common application of PM synchronous motors is in the manufacturing sector, where they are utilized in conveyor systems and robotic arms for precise handling and movement of materials. The versatility of these motors allows them to operate effectively under varying load conditions, a feature that is particularly beneficial in dynamic environments. Additionally, the automotive industry is increasingly deploying PM synchronous motors in electric and hybrid vehicles due to their compact design and ability to provide high performance with minimal energy consumption. According to a market analysis by Research and Markets, the global PM synchronous motor market is expected to grow at a CAGR of 13.2% from 2021 to 2027, underscoring the rising demand for this technology across diverse industrial applications.

Permanent Magnet (PM) synchronous motors are increasingly favored in various applications due to their high efficiency and precise control capabilities. However, several factors can significantly affect their performance and efficiency. One major factor is the temperature of the motor. As temperatures rise, the magnet's properties can degrade, leading to a reduction in torque and overall performance. According to a recent industry report by the International Electromechanical Commission, an increase in operating temperature can decrease efficiency by approximately 1% for every 10°C rise over the rated temperature. Thus, managing thermal conditions is crucial for maintaining optimal performance.

Another key factor is the quality of the permanent magnets used in the motor. The material composition and manufacturing processes directly influence the magnetic field strength and stability. Research from the Electric Power Research Institute indicates that using high-quality rare-earth magnets can improve the motor's efficiency by up to 5% compared to those made from lower-quality materials. Additionally, the design of the rotor and stator geometry, including the air gap distance, can also impact performance, with optimized designs leading to reduced losses and enhanced torque output. Proper consideration of these factors is essential for maximizing the operational efficiency of PM synchronous motors in various industrial applications.

When working with Permanent Magnet (PM) synchronous motors, it's crucial to understand some common issues that can arise during their operation. One prevalent problem is overheating, which can be caused by inadequate cooling, continuous overload, or poor alignment in the motor assembly. Overheating not only affects efficiency but can also lead to permanent damage. To troubleshoot this, it’s essential to ensure proper ventilation, regularly check the load conditions, and confirm that the motor's alignment adheres to manufacturer specifications.

Another issue often encountered with PM synchronous motors is issues related to phase failure or irregularities in current supply. Such problems can result in a noticeable drop in performance, vibrations, or even abrupt motor shutdowns. To diagnose these issues, monitoring and analyzing the current and voltage supplies are imperative. Utilizing instruments to detect phase imbalances can help identify faults early on. Furthermore, preventing these issues entails routine maintenance checks, ensuring the electrical connections are secure and that the power supply is stable and predictable. By addressing these common concerns promptly, the reliability and longevity of PM synchronous motors can significantly improve.

| Tip Number | Tip Description | Common Issues | Solution |

|---|---|---|---|

| 1 | Understand motor specifications | Incorrect voltage ratings | Verify voltage and frequency requirements |

| 2 | Ensure proper alignment | Vibration and noise | Check and adjust mechanical alignment |

| 3 | Evaluate load conditions | Overheating | Monitor load and reduce if necessary |

| 4 | Monitor temperature | Inadequate cooling | Ensure adequate ventilation |

| 5 | Regular maintenance checks | Reduced performance | Schedule routine inspections |