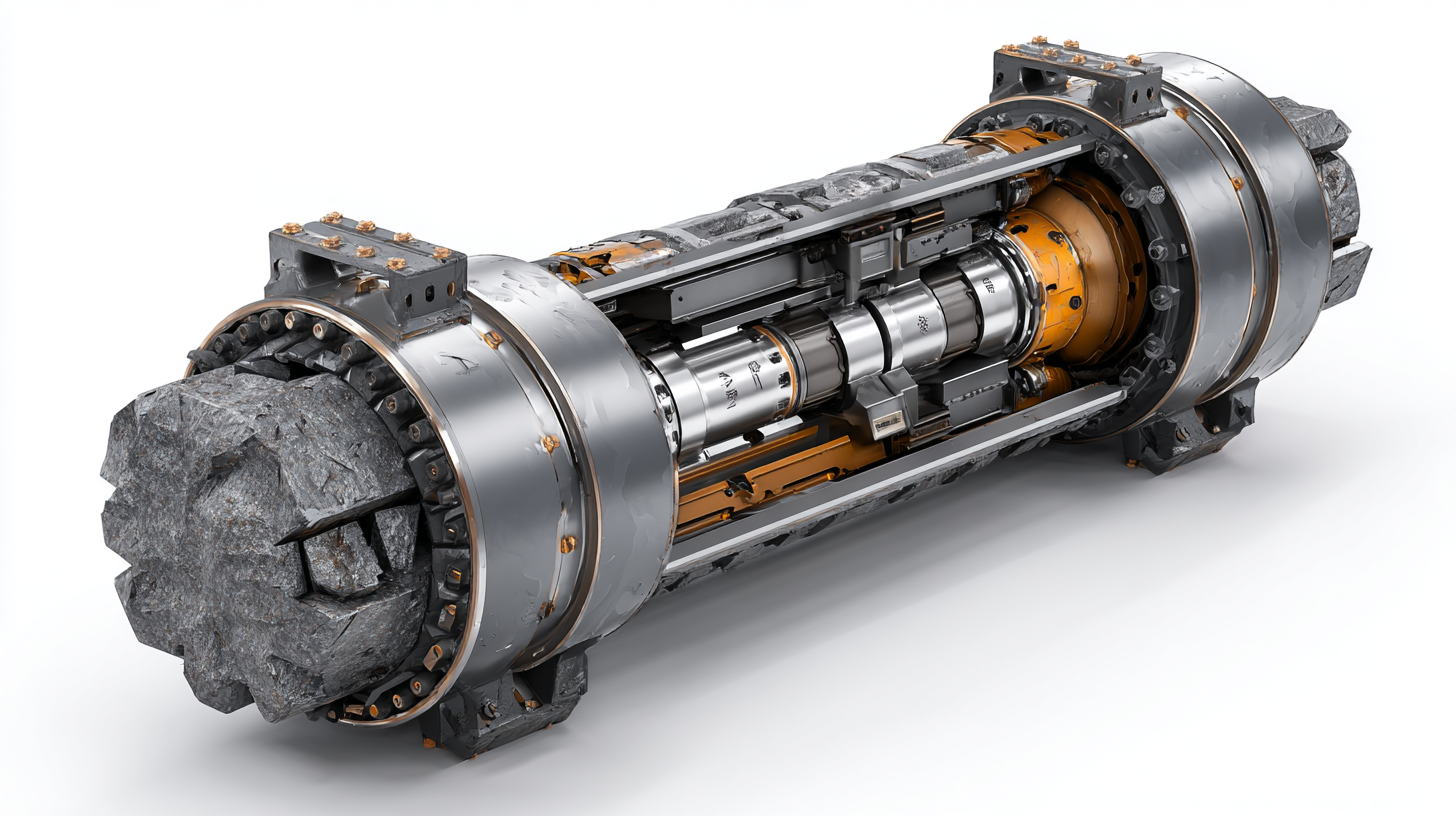

The mining industry has undergone significant transformations over the years, particularly in the development of essential equipment that enhances operational efficiency. One of the key innovations in this sector is the evolution of the Mining Industry Roller Sleeve, which plays a crucial role in various mining applications. This advanced component not only improves the longevity and performance of machinery but also contributes to the overall safety and productivity of mining operations.

As we explore the innovative designs and materials used in modern roller sleeves, it becomes evident how these enhancements offer substantial benefits to mining companies, from reduced maintenance costs to improved environmental sustainability. This guide aims to delve into the various types of Mining Industry Roller Sleeves, outlining their features and advantages, while also providing insights into how they can be effectively integrated into current mining practices for optimal results.

In the mining industry, roller sleeves play a crucial role in ensuring operational efficiency and equipment longevity. These components, typically made from durable materials, are designed to withstand the extreme conditions found in mining environments, including high load capacities and abrasive materials. According to a report by Grand View Research, the global mining equipment market is expected to reach USD 150 billion by 2025, underscoring the importance of resilient parts like roller sleeves in maintaining productivity within this growing sector.

Recent innovations in roller sleeve technology have led to significant improvements in performance and maintenance. Advanced materials, such as polyurethane and composite blends, enhance resistance to wear and corrosion, greatly extending the lifespan of these sleeves. A study by the International Journal of Mining Science and Technology highlighted that using upgraded roller sleeves could reduce system downtimes by up to 20%, translating into substantial cost savings for mining operations. As the industry continues to evolve, the ongoing development of roller sleeve technology represents a key area for optimizing performance and minimizing operational disruptions.

The mining industry has witnessed significant advancements in roller sleeve design and materials, reflecting the need for enhanced efficiency and durability in operations. Traditionally, roller sleeves were made from standard materials that could not withstand the harsh conditions of mining environments. However, recent innovations have introduced advanced composites and alloy materials that exhibit superior wear resistance and strength, reducing maintenance downtime and operational costs.

Furthermore, modern roller sleeves now incorporate innovative geometries and surface treatments that improve their performance. For instance, the introduction of anti-friction coatings minimizes resistance, allowing for smoother operation and increased energy efficiency. Additionally, some designs feature modular components that facilitate easy replacement, thereby decreasing the time and labor involved in maintenance tasks. These advancements not only extend the lifespan of roller sleeves but also contribute to the overall sustainability of mining operations, aligning with industry goals for reducing the environmental impact and increasing productivity.

The modern mining industry is experiencing a significant transformation with the introduction of innovative roller sleeves designed to enhance efficiency and productivity. These advancements are reflected in the projected growth of the composite roller market, which is anticipated to reach USD 261.1 million by 2035, exhibiting a robust CAGR of 5.8% between 2025 and 2035. Such innovations not only improve operational efficiency but also reduce maintenance costs, supporting a more sustainable approach in mining operations.

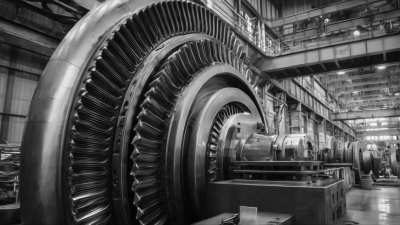

High-pressure grinding rollers (HPGR) are pivotal in increasing productivity within the mining sector. As reported in 2022, the HPGR market is projected to witness substantial growth, driven by their rising adoption in both the mining and cement industries. These rollers enhance the comminution process, allowing for finer particle size reduction and improved ore recovery, which directly translates to higher yields.

Consequently, the integration of modern roller sleeves and HPGRs emerges as a crucial strategy for mining companies aiming to optimize their operations and drive financial performance in a competitive market.

The mining industry has seen significant transformations with the introduction of modern roller sleeves, which offer distinct advantages over traditional materials. Traditional roller sleeves, typically made from steel or plain rubber, can exhibit issues such as wear and tear, leading to increased maintenance costs and frequent replacements. In contrast, modern roller sleeves, often enhanced with advanced materials and coatings, provide improved durability and resistance to harsh mining conditions. Innovations such as nanocoated expanded polystyrene have emerged, which not only enhance performance but also contribute to sustainability by minimizing the environmental impact associated with mining operations.

Moreover, the comparative effectiveness of traditional versus modern roller sleeves extends to their role in energy optimization. Recent studies highlight the potential of modern technologies, such as semi-mobile in-pit crushers and conveyors, in reducing energy consumption during hauling processes. As the industry gears towards sustainability, enhanced roller sleeves could complement these strategies by lowering friction and operational energy costs, aligning with the mining sector's goals of transitioning to a more sustainable model. The embrace of advanced materials and innovative designs signifies a pivotal shift that promises not only efficiency but also a commitment to reducing the ecological footprint of mining activities.

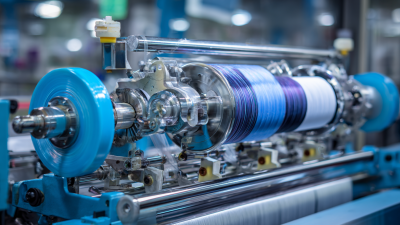

As the mining industry progresses into an era driven by technology, the role of roller sleeves has become increasingly pivotal. Innovations in material science and engineering have significantly enhanced the durability and performance of these components. According to a recent report by Technavio, the global mining equipment market is expected to grow by over 4% from 2023 to 2028, highlighting the increasing reliance on technologically advanced solutions in mining operations. Modern roller sleeves, engineered with advanced polymers and composites, demonstrate improved wear resistance and efficiency, leading to reduced maintenance costs and downtime.

The integration of IoT and predictive analytics is another trend reshaping roller sleeve technology. By incorporating sensor technologies, mining operators can monitor the real-time performance of roller sleeves, thus optimizing their operational lifespan and performance. A study by MarketsandMarkets indicates that the IoT in the mining industry is set to reach a market size of $24 billion by 2027, facilitating a data-driven approach to maintenance and operation. This technological evolution not only promises enhanced productivity but also ensures safer mining practices, ultimately benefiting the industry as a whole.