As the global energy landscape continues to evolve, the significance of energy efficiency has never been more pivotal.

Permanent Magnet Synchronous Motors (PMSMs) have emerged as a leading technology in this arena, offering enhanced performance and reliability compared to traditional induction motors.

According to a report by the U.S. Department of Energy, PMSMs can achieve efficiencies exceeding 95%, which not only reduces electricity consumption but also lowers greenhouse gas emissions.

Furthermore, the global market for PMSMs is projected to reach USD 30.3 billion by 2025, highlighting the increasing adoption of these motors across various industries, including manufacturing, transportation, and renewable energy systems.

As industries strive to meet stringent energy efficiency standards and sustainability goals, the exploration of PMSMs promises to unlock significant potential for reducing energy costs while promoting a greener future.

Permanent Magnet Synchronous Motors (PMSMs) have emerged as a leading technology in this arena, offering enhanced performance and reliability compared to traditional induction motors.

According to a report by the U.S. Department of Energy, PMSMs can achieve efficiencies exceeding 95%, which not only reduces electricity consumption but also lowers greenhouse gas emissions.

Furthermore, the global market for PMSMs is projected to reach USD 30.3 billion by 2025, highlighting the increasing adoption of these motors across various industries, including manufacturing, transportation, and renewable energy systems.

As industries strive to meet stringent energy efficiency standards and sustainability goals, the exploration of PMSMs promises to unlock significant potential for reducing energy costs while promoting a greener future.

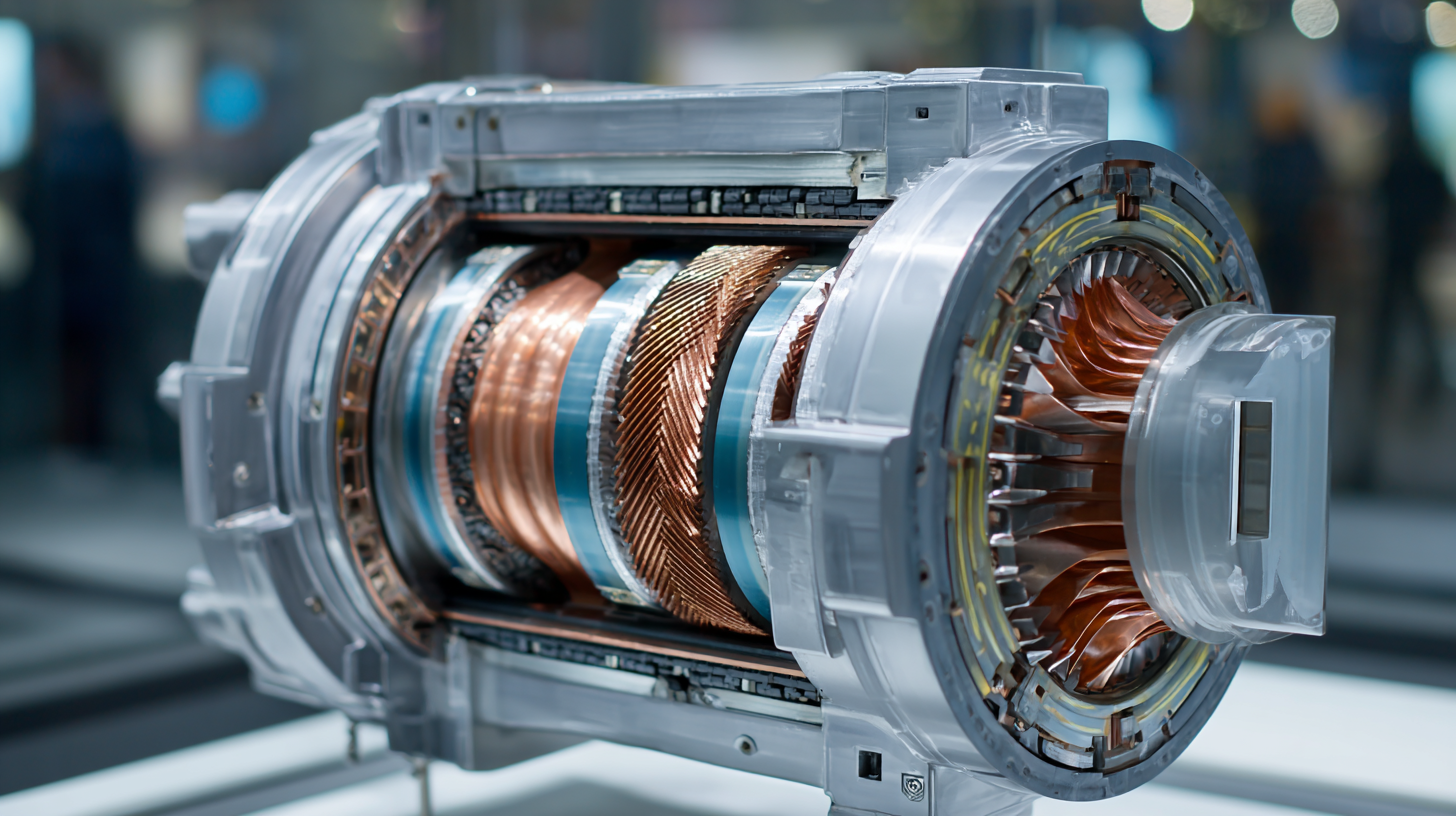

Permanent Magnet Synchronous Motors (PMSMs) have emerged as a leading technology in the quest for energy efficiency in various industrial applications. Unlike traditional induction motors, PMSMs utilize permanent magnets, enabling them to achieve higher efficiencies, typically exceeding 90%. According to a report by the U.S. Department of Energy, the use of PMSMs in industrial fans and pumps can result in energy savings of up to 30% compared to their conventional counterparts. This significant reduction not only enhances operational performance but also contributes to lower carbon emissions, aligning with global sustainability goals.

The advancements in PMSM technology are driven by innovations in materials and design, which enhance their operational effectiveness. For instance, the integration of high-energy-density magnets and advanced manufacturing techniques has resulted in motors that deliver improved torque characteristics and reduced size. A study published in the IEEE Transactions on Industry Applications highlights that the efficiency improvement from deploying PMSMs can lead to reduced lifecycle costs, making them a robust investment for companies aiming to optimize their energy usage. As industries increasingly prioritize energy efficiency, the role of PMSMs is set to expand, paving the way for a cleaner and more sustainable future.

The rise of Permanent Magnet Synchronous Motors (PMSMs) in energy-efficient applications marks a significant trend in the global motor industry. As businesses and industries aim to reduce their carbon footprint, PMSMs are gaining popularity due to their superior efficiency and performance. These motors are being increasingly favored in applications that require high performance while maintaining low energy consumption. The energy-efficient motor market is projected to expand significantly, reflecting the growing preference for motors that adhere to strict efficiency standards, classified under various levels (IE1 to IE5).

Moreover, advancements in technology have also fueled the demand for energy-efficient solutions across diverse sectors, from electric vehicles to industrial automation. The optimization of multi-motor systems through innovative inverter topologies is enhancing energy utilization and reducing operational costs. In particular, the comparative analysis of different motor types, such as brushless DC and switched reluctance motors, showcases the potential for off-grid water pumping systems. As these technologies evolve, the focus on energy efficiency will continue to shape the landscape of motor applications, driving sustainable practices across industries.

| Application Area | Efficiency (%) | Market Growth Rate (%) | Projected Adoption by 2025 (%) | Energy Savings (MWh/year) |

|---|---|---|---|---|

| Industrial Automation | 95 | 6.5 | 70 | 5000 |

| HVAC Systems | 90 | 7.2 | 65 | 3000 |

| Electric Vehicles | 92 | 15 | 80 | 15000 |

| Renewable Energy Systems | 94 | 5.5 | 75 | 8000 |

| Pumps and Fans | 88 | 6.0 | 60 | 4000 |

Permanent Magnet Synchronous Motors (PMSMs) are proving to be a game changer in the realm of energy efficiency, particularly when compared to traditional motor technologies. The global movement towards energy-efficient motors aligns with the increasing demand for reduced energy consumption and enhanced performance. The estimated global market worth of energy-efficient motors is poised to reach remarkable heights, underscoring growing investments in technologies that minimize energy waste.

One significant advancement in PMSM technology is the development of intelligent optimization algorithms, such as the IO-FOC, which optimize dynamic response and steady-state performance. This level of innovation not only improves efficiency but also enhances the overall operational lifespan of electric motors. Additionally, the adoption of machine learning-based controllers for PMSM drives exemplifies the shift towards more adaptive and intelligent motor systems, capable of adjusting according to real-time conditions and operational demands.

Tips: Consider implementing PMSMs in your energy systems to maximize efficiency and reduce operating costs. Moreover, regularly exploring advancements in motor technology can help you stay ahead of the curve and capitalize on emerging trends that promise better performance and lower energy consumption.

As industries increasingly seek ways to reduce energy consumption, Permanent Magnet Synchronous Motors (PMSMs) have emerged as a leading solution. Real-world case studies highlight their potential for significant energy savings across various applications, particularly in manufacturing and HVAC systems. Companies that have integrated PMSMs often report efficiency improvements averaging between 10% to 30%, directly translating to lower operational costs and enhanced sustainability practices.

Tip: When considering PMSM implementations, it's essential to conduct a thorough energy audit to establish baseline performance metrics. This will enable precise measurement of energy savings post-implementation, ensuring that the investment is justified by quantifiable results.

Additionally, case studies reveal the importance of proper sizing and control strategies in maximizing the benefits of PMSMs. For instance, the adoption of advanced control algorithms can optimize motor performance under varying load conditions, further boosting energy efficiency. By focusing on these aspects, businesses can make informed decisions that align with their operational goals and sustainability targets.

Tip: Collaborate with experienced engineers and energy consultants during the design phase to tailor PMSM solutions to your specific needs. This proactive approach can maximize the return on investment and enhance overall system performance.

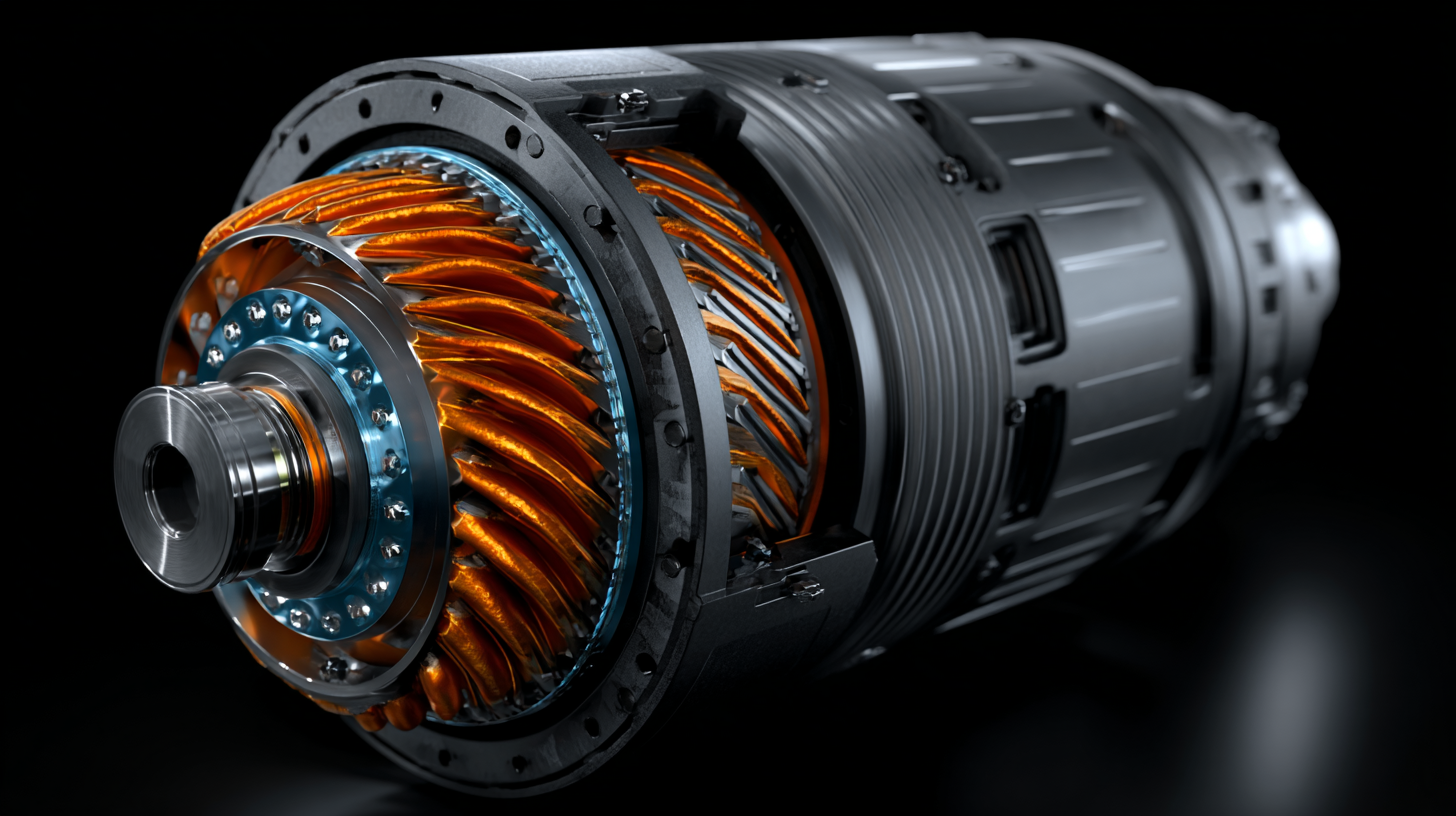

Permanent magnet synchronous motors (PMSMs) stand at the forefront of energy efficiency innovations in various industries. As technology advances, PMSMs are becoming increasingly sophisticated, enhancing their performance while reducing energy consumption. The inherent characteristics of PMSMs—such as high torque density, excellent speed control, and low running losses—make them ideal candidates for integration into applications ranging from electric vehicles to industrial machinery. These motors not only contribute to lower operational costs but also play a crucial role in meeting stringent energy efficiency standards globally.

Future innovations in PMSM technology are likely to focus on materials science and improved design techniques. The development of high-energy magnets and advanced cooling systems can further increase efficiency and reliability, paving the way for their widespread adoption. Additionally, integrating smart technologies such as IoT capabilities will allow for better monitoring and optimization of motor performance in real-time. As PMSMs evolve, they will not only set new benchmarks for energy efficiency but also encourage sustainability practices across various sectors, significantly reducing carbon footprints worldwide.

This chart illustrates the projected energy efficiency improvements attributed to advancements in Permanent Magnet Synchronous Motors (PMSM) technology over the next decade. The data reflects percentage increases in energy efficiency standards from 2023 to 2032.