As we navigate the complexities of energy consumption and the pressing need for sustainability, innovative technologies are stepping into the spotlight to revolutionize our approach to energy efficiency. Among these advancements, Interior Permanent Magnet (IPM) technology is emerging as a game-changer in various applications, offering enhanced performance and reduced energy losses. This introduction will outline how IPM can be leveraged effectively to maximize energy efficiency in both residential and industrial settings. By examining the underlying principles of IPM technology, its integration into existing systems, and the tangible benefits it brings, we can better understand its potential to transform the landscape of energy consumption. As we embark on this journey to explore the future of energy efficiency, we will provide practical insights and actionable steps on how to implement IPM solutions in everyday life, ultimately contributing to a greener and more sustainable future.

In conclusion, the integration of IPM technology is not just a step forward in energy efficiency; it's a vital part of creating a sustainable energy future. By adopting these technologies in our daily lives, we take significant strides towards reducing energy consumption and enhancing performance in both private and industrial sectors.

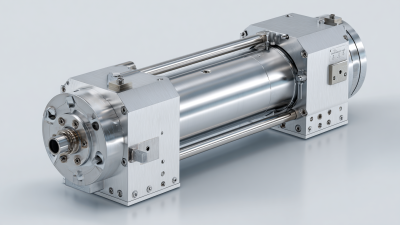

Interior Permanent Magnet (IPM) technology is revolutionizing the way we approach energy efficiency in various applications, particularly in electric motors. At its core, IPM technology utilizes permanent magnets embedded within the rotor, allowing for more effective magnetic field utilization. This design not only enhances performance but also reduces energy losses, making it a prime choice for environmentally conscious engineering solutions.

The advantages of IPM technology extend beyond mere efficiency. It enables smoother operation and greater torque density, which translates into smaller and lighter motor designs. Industries ranging from automotive to industrial automation are leveraging IPM-driven electric motors to meet stricter energy standards while maintaining high productivity levels. By exploring the fundamental mechanics of IPM technology, we can unlock new potentials for reducing our carbon footprint and optimizing energy consumption across various sectors.

The advent of Interior Permanent Magnet (IPM) technology is revolutionizing the realm of energy efficiency. This innovative approach leverages the unique properties of permanent magnets, allowing systems to operate with reduced energy consumption while maintaining high performance. By minimizing energy losses in electric motors and generators, IPM systems provide significant energy savings, making them an attractive option for industries seeking to lower their operational costs and carbon footprint.

One of the primary advantages of permanent magnet systems lies in their ability to deliver superior torque and power density compared to traditional induction motors. This enhanced capability enables machines to perform more efficiently under varying load conditions, further contributing to overall energy efficiency. Additionally, the compact design of IPM systems leads to smaller and lighter machinery, which not only saves space but also reduces material usage and promotes sustainability. By integrating these systems into various applications, businesses can achieve both economic and environmental benefits, paving the way for a more energy-efficient future.

| Technology | Energy Savings (%) | Maintenance Frequency (months) | Typical Lifespan (years) | Applications |

|---|---|---|---|---|

| Interior Permanent Magnet Motors | 30 | 24 | 15 | HVAC, Industrial Drives |

| Permanent Magnet Generators | 25 | 12 | 20 | Wind Energy, Hydro Power |

| Electric Vehicles with Permanent Magnet Motors | 40 | 18 | 15 | Transportation, Automotive |

| Permanent Magnet AC Drives | 20 | 36 | 10 | Pumps, Fans, Compressors |

The integration of Interior Permanent Magnet (IPM) technology into modern energy applications is transforming the landscape of energy efficiency.

As the quest for sustainable solutions becomes increasingly urgent, IPM systems are being implemented widespread across various sectors.

These systems provide significant advantages in electric vehicle (EV) motors, particularly as traditional models like Permanent Magnet Synchronous Motors (PMSM) begin to face challenges associated with the scarcity and cost of rare earth elements.

The integration of Interior Permanent Magnet (IPM) technology into modern energy applications is transforming the landscape of energy efficiency.

As the quest for sustainable solutions becomes increasingly urgent, IPM systems are being implemented widespread across various sectors.

These systems provide significant advantages in electric vehicle (EV) motors, particularly as traditional models like Permanent Magnet Synchronous Motors (PMSM) begin to face challenges associated with the scarcity and cost of rare earth elements.

Researchers are actively exploring innovative alternatives to PMSM, focusing on developing electric motors that do not rely on rare earth materials.

This shift not only promises to reduce production costs but also aligns with a global push towards sustainable practices.

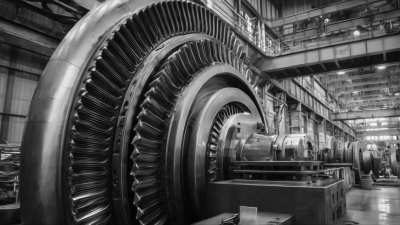

In wind energy, for example, new modeling techniques for double-side slotted axial flux permanent magnet generators (PMGs) are emerging to enhance the efficiency of small-scale wind energy systems.

Tips: When considering energy efficiency solutions, prioritize technologies that minimize environmental impact.

Additionally, staying informed about the latest advancements in motor technology can yield significant benefits for both cost management and operational efficiency.

Remember to evaluate compatibility with existing systems to ensure seamless implementation of these innovative solutions.

Interior Permanent Magnet (IPM) technology is revolutionizing energy efficiency across various sectors, with significant implications for sustainability and cost-effectiveness. According to a report by the International Energy Agency (IEA), improving energy efficiency in buildings and industries could lead to a cumulative reduction of 70% in global energy demand by 2030. IPM motors, known for their high power density and efficiency, contribute to this goal by minimizing energy losses and maximizing output.

Additionally, the U.S. Department of Energy estimates that widespread adoption of energy-efficient technologies like IPM could save businesses over $300 billion annually by 2030. This immense cost savings is complemented by a substantial reduction in carbon emissions, reinforcing the idea that energy efficiency is a pivotal aspect of sustainable development. As companies increasingly recognize the dual benefits of reduced operational costs and enhanced environmental stewardship, the integration of IPM technology into their energy solutions remains a key priority for future innovations.

This chart illustrates the energy savings achieved by various technologies using Interior Permanent Magnet Technology, highlighting their potential impact on sustainability and overall cost-effectiveness in energy consumption.

As the world seeks innovative solutions for energy efficiency, Interior Permanent Magnet (IPM) technology is emerging as a game-changer. This technology not only enhances motor performance but also significantly reduces energy consumption in applications ranging from electric vehicles to industrial machinery. The future trends in IPM technology suggest that as advancements continue, we can anticipate even greater efficiency improvements, especially with the integration of smart technologies that optimize energy use in real-time.

To maximize the benefits of IPM technology, consider these tips: First, stay updated on the latest advancements in digital control systems that can enhance the performance of IPM motors. Implementing advanced controls can lead to better energy management and lower operational costs. Secondly, when upgrading your equipment, look for IPM solutions that are specifically designed for your application needs, as tailored technology can lead to significant efficiency gains.

Additionally, businesses should evaluate their energy strategies by incorporating IPM technology into their sustainability goals. Investing in these innovative solutions not only improves energy efficiency but also contributes positively to environmental impact. As the industry evolves, aligning your operations with the latest trends in IPM can provide a competitive edge while fostering a greener future.