In recent years, the demand for Permanent Magnet Synchronous Motors (PMSMs) has surged. According to a report by Allied Market Research, the global PMSM market was valued at $21.6 billion in 2020 and is projected to reach $42.4 billion by 2027. Such impressive growth reflects the increasing emphasis on energy efficiency and performance in various applications.

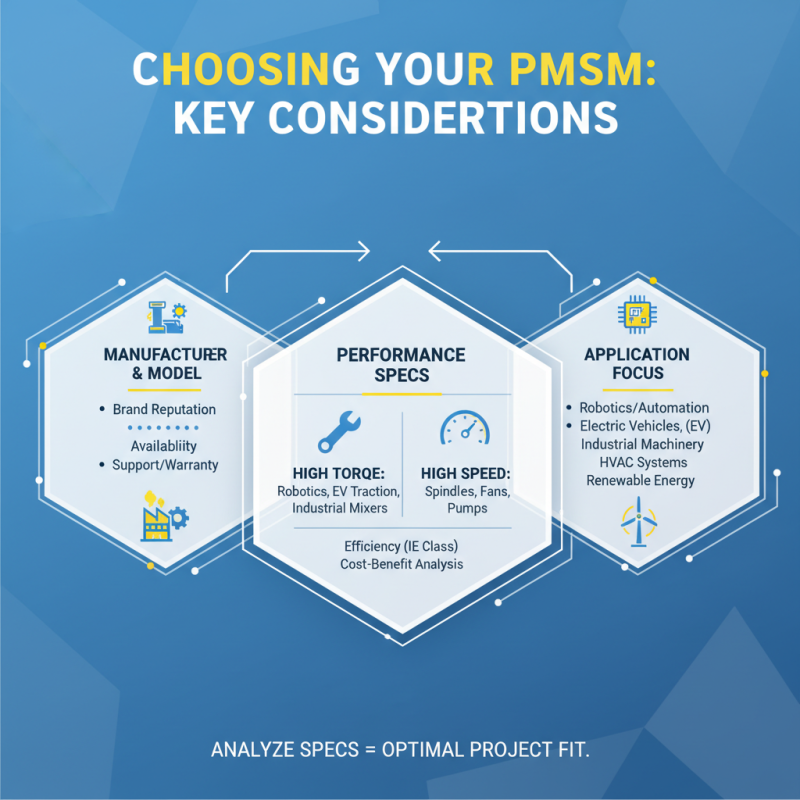

Experts note that choosing the right PMSM can be challenging. “Selecting the proper motor for your application can significantly impact efficiency and system performance,” remarks Dr. John Smith, a leading authority in motor technologies. This highlights the need for careful evaluation of specifications and requirements when considering a PMSM.

Potential users should weigh several factors, including torque, speed, and thermal management. It is crucial to understand that a mismatch between motor choice and application can lead to inefficiencies. Industry professionals often witness this oversight, underscoring the importance of thorough project analysis. Investing time in selecting the right Permanent Magnet Synchronous Motor can yield long-term benefits, avoiding costly mistakes down the road.

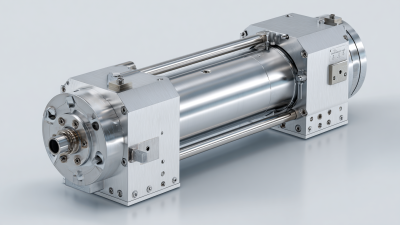

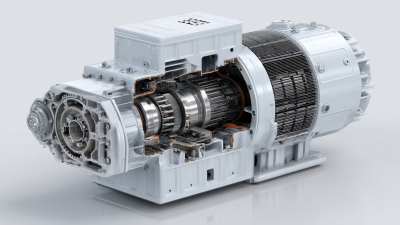

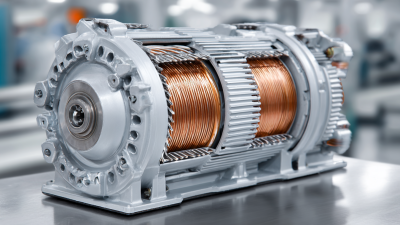

Permanent Magnet Synchronous Motors (PMSMs) are widely used for their efficiency and performance. They operate using a rotating magnetic field created by permanent magnets. This design allows for precise control of speed and torque, making them ideal for various applications. Understanding their basics can help you make informed choices.

When selecting a PMSM, consider key factors like power requirements and load characteristics. The motor's efficiency is crucial, impacting your project's energy consumption. Conducting a load analysis can reveal what specifications you need. Sometimes, smaller or larger motors may not meet expectations. Testing under real conditions can reveal potential issues.

Another aspect to ponder is the size and weight of the motor. Compact designs can save space, but they may have limitations in power. Balancing size with performance can be tricky. Always evaluate the intended application thoroughly. Exploring different configurations will help you understand trade-offs. Not every solution fits every scenario. Adjustments may be necessary to achieve optimal results.

When selecting a permanent magnet synchronous motor (PMSM) for your project, there are key factors to consider. First, determine the motor's torque and speed requirements. Different applications need varying torque levels. For example, a conveyor system may need high torque at low speeds, while a fan could require high speed and low torque. Understanding these needs helps narrow your choices.

Next, think about the environment where the motor will operate. Will it be exposed to moisture or dust? Harsh environments require motors with specific protective ratings. Additionally, consider the motor's size and weight. A motor that is too large may complicate your design. A compact yet powerful motor can optimize space and efficiency.

Efficiency ratings are also important. A less efficient motor can lead to higher energy costs over time. Be cautious, though; higher efficiency ratings can sometimes increase the upfront cost. Assess the cost versus long-term savings carefully. You may need to adjust your budget for the best outcome. Pay attention to these factors, as they can significantly impact the performance and longevity of your project.

| Factor | Description | Importance Level |

|---|---|---|

| Power Rating | The maximum output power the motor can deliver. | High |

| Torque Characteristics | How much torque the motor can produce at different speeds. | High |

| Efficiency | How effectively the motor converts electrical energy to mechanical energy. | Medium |

| Size and Weight | Physical dimensions and mass, affecting installation and handling. | Medium |

| Control System Compatibility | How easily the motor integrates with existing control systems. | High |

| Cooling Requirements | Need for additional cooling systems based on operating conditions. | Medium |

| Cost | Total expense of the motor including installation and maintenance. | High |

When choosing a permanent magnet synchronous motor (PMSM), application requirements are crucial. Consider factors like torque, speed, and efficiency. Each project has unique needs. For example, a robotics application may demand rapid accelerations and precise control. On the other hand, a conveyor system could prioritize steady torque at lower speeds.

Another essential aspect is the environment where the motor will operate. Motors must withstand specific temperatures, humidity, or even dust. If these factors aren't well-evaluated, performance could suffer. An unsuitable motor might lead to failures or maintenance issues. This could result in costly downtimes or inefficient operations. It's imperative to fully understand these conditions.

Power supply is another key consideration. Does the project require high voltage or low voltage? The motor's winding configuration can significantly impact performance as well. An incorrect choice here may lead to poor integration with existing systems. Consulting with engineers and conducting feasibility studies can help. This process may feel tedious, but it is necessary for optimal results.

Choosing a permanent magnet synchronous motor (PMSM) involves careful evaluation of efficiency and cost-effectiveness. Your project's needs will dictate the specifications. A high-efficiency motor can reduce energy costs over time. However, initial costs may be higher. It’s essential to balance these factors effectively.

Consider the application of the motor. Different industries have varying efficiency requirements. For example, a motor in a continuous operation setting may demand higher reliability. In some cases, the lower cost of a less efficient motor might seem appealing. But long-term savings can be overlooked. Analyzing usage patterns helps to make an informed choice.

Remember to assess installation and maintenance costs as well. A more efficient motor may require more investment upfront, but can result in lower energy consumption. Take time to calculate potential savings. Gather data on similar projects for reference. Sometimes, what looks good on paper needs real-world testing. Being open to experimentation can reveal insights that statistics may not show.

Choosing the right permanent magnet synchronous motor (PMSM) involves considering various manufacturers and models. Each manufacturer specializes in different aspects, such as efficiency, cost, and performance. Some motors are designed for high torque applications, while others focus on speed. Analyzing these specifications helps identify the best fit for your project.

When comparing models, it is essential to evaluate performance metrics. Look at efficiency ratings, torque curves, and speed capabilities. Visualizing motor performance helps in making an informed decision. Additionally, consider the support and documentation provided by manufacturers. This can greatly impact your project's success. Sometimes, manufacturers lack clarity in their specifications, which can lead to confusion.

It's also important to gather feedback from users. Reviews and case studies provide insights that specifications do not. However, keep in mind that experiences may vary. What works for one project might not work for another. Balancing data and user experiences will create a better understanding of which model fits your needs.