The efficiency of modern power generation is critically tied to the durability of key components, one of which is the Power Plant Roller Sleeve. Recent industry reports indicate that approximately 40% of energy losses in thermal power plants can be attributed to wear and failure of mechanical components, including roller sleeves. According to the International Energy Agency (IEA), enhancing the reliability of these components can improve overall energy efficiency by up to 10% in some plants.

As power generation facilities strive to meet the increasing global energy demands—projected to rise by 1.5% annually—understanding the impact of roller sleeve materials and design on their performance becomes essential. This exploration highlights the importance of investing in durable roller sleeve technologies, which can not only minimize operational downtime but also contribute to more sustainable energy production processes.

The role of roller sleeve material in enhancing

power plant efficiency is paramount in modern energy generation. According to a report from the

International Energy Agency (IEA), energy efficiency improvements in power plants can lead to a

significant reduction in CO2 emissions, with potential savings of up to 1.5 gigatons annually by 2030.

Utilizing advanced materials for roller sleeves can directly contribute to these efficiency gains by lowering

friction and wear in mechanical systems, resulting in better energy transmission and reduced operational costs.

The role of roller sleeve material in enhancing

power plant efficiency is paramount in modern energy generation. According to a report from the

International Energy Agency (IEA), energy efficiency improvements in power plants can lead to a

significant reduction in CO2 emissions, with potential savings of up to 1.5 gigatons annually by 2030.

Utilizing advanced materials for roller sleeves can directly contribute to these efficiency gains by lowering

friction and wear in mechanical systems, resulting in better energy transmission and reduced operational costs.

Recent studies indicate that roller sleeves made from composite materials exhibit durability improvements over traditional metal options. For instance, research published in the Journal of Energy Resources Technology shows that composite roller sleeves can reduce wear rates by as much as 30%, which translates to longer maintenance intervals and reduced downtime. By integrating these materials, power plants not only enhance their operational efficiency but also align with sustainability goals, aiming to maximize output while minimizing environmental impact. The transition to high-performance roller sleeve materials is therefore essential for facilities striving to remain competitive in an increasingly environmentally-conscious market.

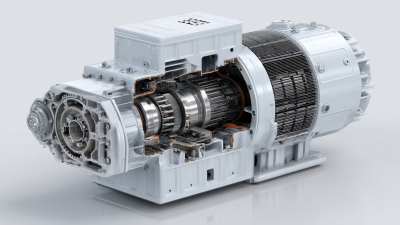

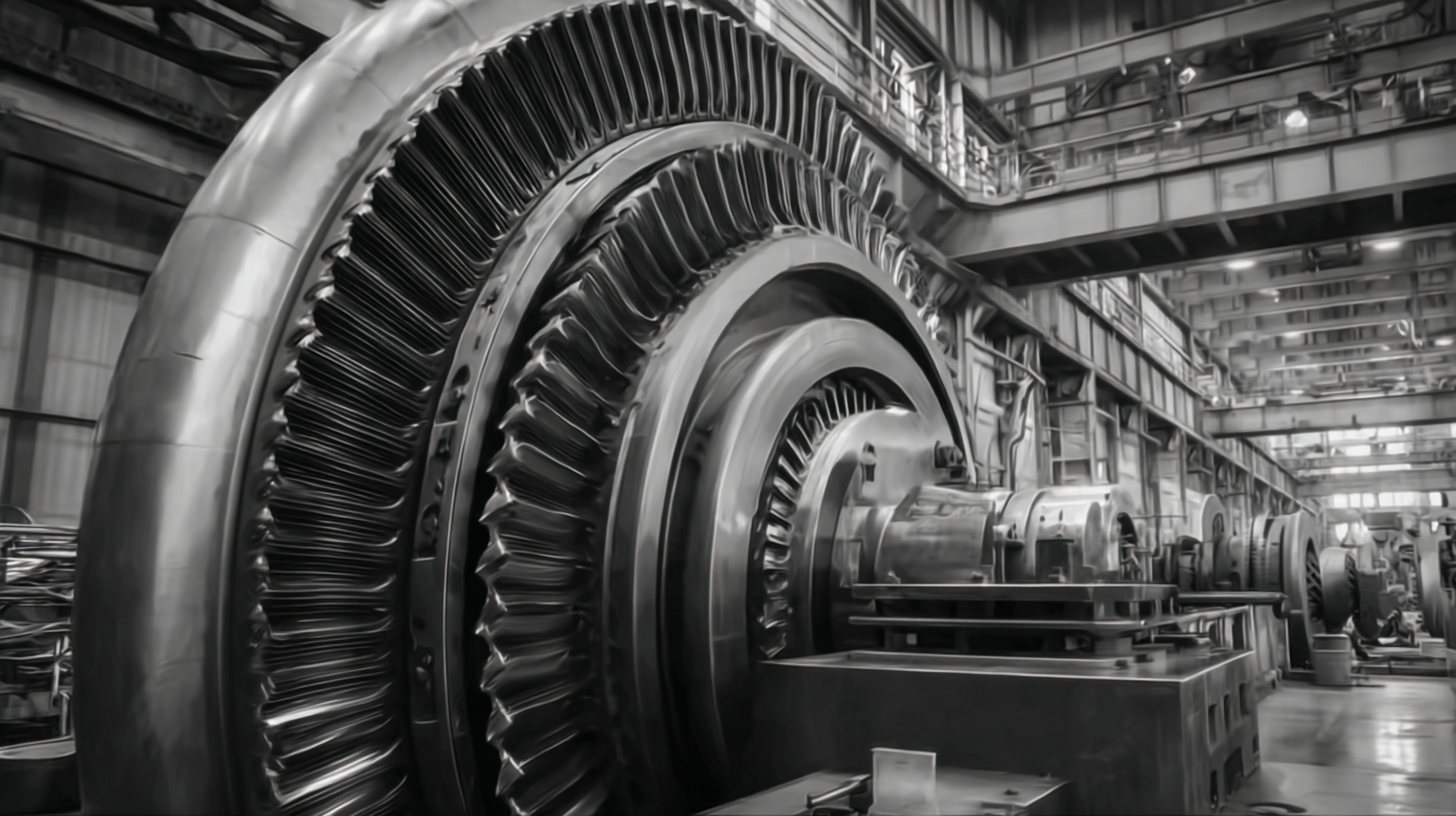

The wear and tear of roller sleeves in power plants can significantly impact fuel consumption rates, leading to inefficiencies in energy production. Roller sleeves are critical components that facilitate the smooth operation of turbines and generators. As these components degrade over time, they can increase friction and reduce the effective transfer of energy. This not only leads to higher operational costs but also directly affects the plant's overall efficiency by necessitating greater fuel inputs to maintain output levels.

Furthermore, the relationship between roller sleeve wear and fuel consumption rates is essential for optimizing performance in modern power generation. Regular monitoring and maintenance of roller sleeves can help in identifying patterns of wear that correlate with increased fuel usage. By analyzing data on wear progression and its effects on energy output, operators can implement predictive maintenance strategies that minimize downtime and enhance fuel efficiency. This proactive approach can lead to significant cost savings, improved sustainability, and a more reliable power generation process.

The longevity of roller sleeves in power plants is significantly influenced by the maintenance protocols implemented during operation. Regular inspections and preventative maintenance routines play a critical role in identifying potential wear and tear before they escalate into major failures. By adhering to a strict maintenance schedule, operators can ensure that roller sleeves operate within optimal conditions, thereby extending their life cycle and enhancing overall system reliability.

Furthermore, the choice of maintenance techniques, whether predictive or reactive, can greatly affect operational performance. Predictive maintenance, which utilizes data analytics to anticipate issues, allows for timely interventions that mitigate downtime and improve the efficiency of power generation. In contrast, a reactive maintenance approach often leads to unexpected failures, resulting in costly operational disruptions. Therefore, optimizing maintenance strategies not only increases roller sleeve durability but also bolsters the energy efficiency of modern power plants, ensuring a more sustainable and economically viable power generation process.

This chart illustrates the relationship between roller sleeve durability and operational efficiency in power generation over different maintenance scenarios. The efficiency peaks at around 15 years of durability, while maintenance frequency varies, highlighting the need for optimized maintenance protocols.

The efficiency of modern power generation relies heavily on the durability and design of roller sleeves in power plants. Upgraded roller sleeve designs are not only a mechanical improvement but also a strategic enhancement that can lead to significant energy savings. By conducting thorough assessments of these components, power plants can identify wear patterns and optimize their operations accordingly. This proactive approach leads to a reduction in energy consumption, showcasing how critical these small yet vital components are in the broader context of energy production.

Tip: Regular maintenance of roller sleeves can enhance their lifespan and efficiency. Scheduling routine inspections allows power plant operators to catch potential issues early, ensuring that the upgraded designs perform consistently at their peak.

The quantification of energy savings from these advanced designs is crucial for justifying investments in new technology. Case studies indicate that modern roller sleeves can reduce friction, improve load distribution, and ultimately lower energy wastage during power generation. This transformation contributes not only to cost savings for power plants but also to a reduced environmental footprint.

Tip: Implementing monitoring systems that track energy use associated with roller sleeve performance can provide valuable insights into cost-saving opportunities and operational efficiency improvements.

The integration of durable roller sleeves in power plants has proven to be a critical factor in enhancing energy production efficiency. Case studies reveal that facilities implementing high-performance materials for their roller sleeves have experienced significant reductions in maintenance downtime and resource costs. For instance, a leading coal-fired power plant upgraded its roller sleeves using advanced composite materials, which not only extended their operational lifespan but also improved the overall reliability of their energy generation process. This shift not only contributed to lower operational expenses but also equipped the plant to meet emerging energy demands more effectively.

Another noteworthy example can be seen in a gas turbine power station where the adoption of abrasion-resistant roller sleeves resulted in notable efficiency gains. The improved durability lessened the frequency of replacements and minimized thermal losses associated with wear and tear. This case highlighted the dual benefits of durability: enhancing equipment performance while simultaneously advancing energy efficiency metrics. The successful implementation of these solutions showcases a broader trend in modern power generation, where material longevity translates directly into both economic savings and a lower environmental impact.