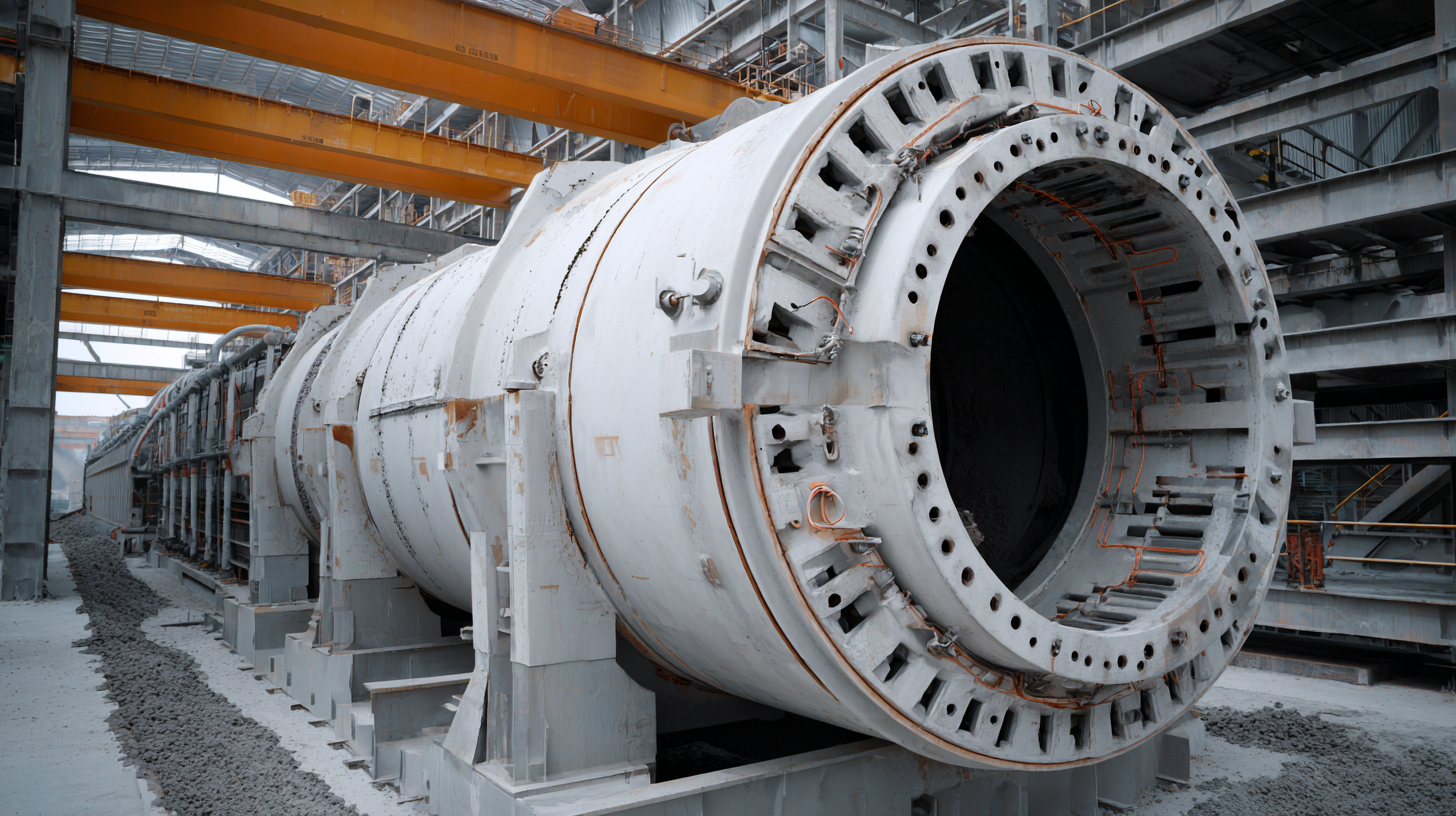

The Cement Industry Roller Sleeve plays a crucial role in enhancing the efficiency and productivity of cement manufacturing processes. As the global demand for cement continues to rise, it becomes imperative for industry stakeholders to adopt innovative solutions that not only optimize operations but also reduce costs and minimize environmental impact. This article explores various strategies and technologies that can be implemented to maximize efficiency within the cement industry, with a special focus on the functionality and advantages of roller sleeves. By examining current trends, innovative materials, and best practices, we aim to provide actionable insights for manufacturers seeking to improve their processes. The insights presented here will help in understanding how the integration of modern engineering solutions and effective maintenance practices can lead to significant advancements in the performance of Cement Industry Roller Sleeves, ultimately contributing to a more sustainable and efficient future for cement production.

In the cement industry, enhancing efficiency in roller sleeve production is paramount. Innovative technologies are currently reshaping how manufacturers approach the production process. According to a recent report by the International Energy Agency, integrating advanced manufacturing techniques can lead to a 20% reduction in energy consumption, significantly lowering operating costs. Automation and smart manufacturing systems are vital components in achieving these efficiency gains, streamlining workflows, and reducing waste.

Implementing predictive maintenance technology can further enhance production efficiency by minimizing unplanned downtimes. Industry studies indicate that predictive maintenance can lead to a 10-15% reduction in operational costs. By employing sensors and IoT devices, manufacturers can monitor real-time data, allowing for timely interventions before issues escalate.

**Tips:** Embrace automation to not only improve operational workflows but also to enhance product quality. Additionally, investing in employee training on new technologies ensures that your workforce is equipped to utilize these innovations effectively. By adopting these strategies, cement industry players can maximize efficiency and maintain a competitive edge.

In today's competitive landscape, the cement industry seeks innovative approaches to improve operational efficiency. One of the most promising strategies is the integration of data analytics into cement manufacturing processes. By harnessing large datasets generated during production, companies can gain critical insights that help streamline operations, reduce waste, and enhance overall performance.

Data analytics allows for real-time monitoring of various parameters, such as temperature, pressure, and material composition. This information facilitates proactive decision-making, enabling manufacturers to identify inefficiencies quickly and implement corrective actions. Furthermore, predictive analytics models can foresee potential equipment failures or production bottlenecks, leading to improved maintenance schedules and minimized downtime. By adopting these advanced analytical techniques, cement manufacturers can optimize their operations, reduce costs, and ultimately improve product quality.

The cement industry is a significant contributor to global carbon emissions, accounting for approximately 7% of total CO2 emissions. In response to the urgent call for sustainability, many companies are adopting innovative practices aimed at reducing their carbon footprint. The implementation of alternative fuels, such as biomass and waste-derived fuels, is a key strategy, as these can reduce CO2 emissions by up to 30% compared to traditional fossil fuels. Furthermore, advances in carbon capture and storage (CCS) technology present a promising avenue for mitigating emissions, with reports suggesting that CCS could potentially reduce emissions from cement production by up to 90% by capturing carbon dioxide before it enters the atmosphere.

In addition to fuel replacement and CCS technologies, optimizing production processes through improved energy efficiency is vital for sustainability. The World Business Council for Sustainable Development (WBCSD) indicates that enhancing energy efficiency could lead to a 20% reduction in energy consumption in cement manufacturing. Strategies such as upgrading equipment and implementing process automation not only help to minimize energy use but also enhance the overall economic performance of cement plants. By embracing these sustainability initiatives, the cement industry can make meaningful progress toward reducing its environmental impact while maintaining competitiveness in a rapidly evolving market.

| Sustainability Initiative | Description | Impact on Carbon Footprint | Investment Required ($) | Estimated Reduction (%) |

|---|---|---|---|---|

| Alternative Fuels | Using waste materials as fuel in the production process | Reduces reliance on fossil fuels | 500,000 | 20 |

| Carbon Capture Technology | Capturing CO2 emissions before they enter the atmosphere | Directly reduces greenhouse gases released | 1,200,000 | 30 |

| Energy Efficiency Improvements | Upgrading machinery to reduce energy consumption | Lower operational energy use | 300,000 | 15 |

| Sustainable Sourcing of Raw Materials | Using locally sourced and sustainable materials | Reduces transportation emissions and supports local economy | 200,000 | 10 |

| Product Innovation | Development of lower-carbon cement formulations | Significantly lowers the carbon intensity of products | 400,000 | 25 |

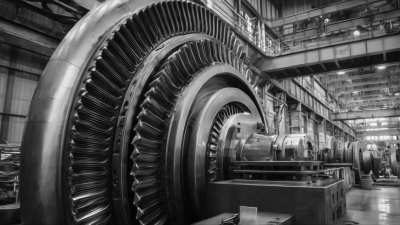

The cement industry is undergoing a transformative shift, particularly in the maintenance practices for roller sleeves, thanks to advancements in automation. Automation technologies, such as predictive maintenance systems powered by IoT sensors, enable real-time monitoring of roller sleeve conditions. This proactive approach not only minimizes unexpected breakdowns but also extends the lifespan of equipment, ultimately leading to significant cost savings for manufacturers.

Furthermore, integrating automated systems streamlines the maintenance workflow by providing instant data analysis and diagnostics. This allows maintenance teams to focus their efforts on high-priority issues and schedule repairs during planned downtimes rather than responding to emergencies. As a result, overall operational efficiency is enhanced, leading to increased productivity and reduced downtime within cement production facilities. The role of automation in this context is critical, paving the way for smarter, more sustainable practices within the industry.

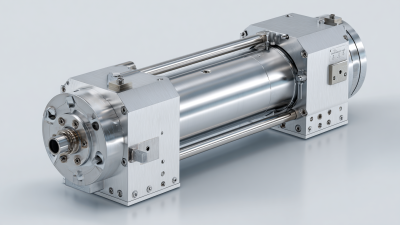

The cement industry is experiencing a transformative phase with the emergence of innovative materials for roller sleeve design that significantly enhance performance and longevity. Recent studies highlight the critical role of lightweight composite materials in industrial applications, allowing for enhanced durability and strength while reducing overall weight. This shift mirrors advancements seen in the field of textiles, where next-generation materials are being developed to offer sustainable alternatives that leverage renewable resources. For instance, composites made from natural fibers like hemp and flax are being considered for mechanical applications due to their excellent strength-to-weight ratios.

Moreover, the integration of advanced technologies, including machine learning, is revolutionizing the way materials are developed and applied within the cement sector. By employing AI-driven methodologies, researchers are uncovering unprecedented insights into material behaviors, leading to innovative roller sleeve designs that can withstand harsh operating conditions while maintaining efficiency. According to industry reports, the shift towards utilizing polymer composites in construction aligns with broader sustainability goals, offering a pathway to reduce environmental impact while optimizing production processes. These advancements not only represent a competitive edge for manufacturers but also pave the way for greener industrial practices.

This chart illustrates the performance improvement and longevity of different roller sleeve materials used in the cement industry.