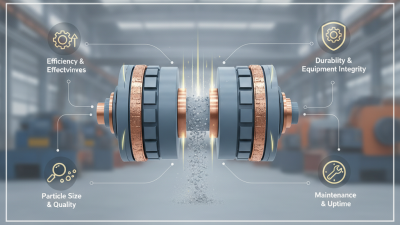

In the world of milling, the role of the Mill Roller Sleeve is crucial. This component directly impacts efficiency and product quality. Optimizing its performance is not just important; it’s essential. Numerous factors influence the lifespan and effectiveness of a Mill Roller Sleeve. Regular maintenance, proper material selection, and adequate alignment are critical aspects.

Operators often overlook small details. Neglecting regular checks can lead to unexpected failures. Even minor wear can significantly affect milling operations. Understanding the materials used for the roller sleeve can contribute to better durability. Knowledge gaps can hinder optimal performance. There’s always room for improvement.

Achieving efficient performance requires a systematic approach. Spreading awareness about best practices encourages a proactive maintenance culture. Learning from previous mistakes is vital. Industry insights can help refine existing processes. The journey towards optimal performance is ongoing, and reflection is key.

Mill roller sleeves play a vital role in the overall performance of milling machines. These components ensure that the grain is processed efficiently. They provide a contact surface that allows for the grinding of material with precision. Proper functionality of the sleeve enhances productivity significantly.

However, many users overlook maintenance needs. Regular inspection and cleaning are essential. Dust and debris can accumulate, impacting performance. Sometimes, the wear and tear are not immediately visible. Neglecting these details can lead to unexpected downtime and costly repairs. Evaluating the condition of your roller sleeves should be a routine practice.

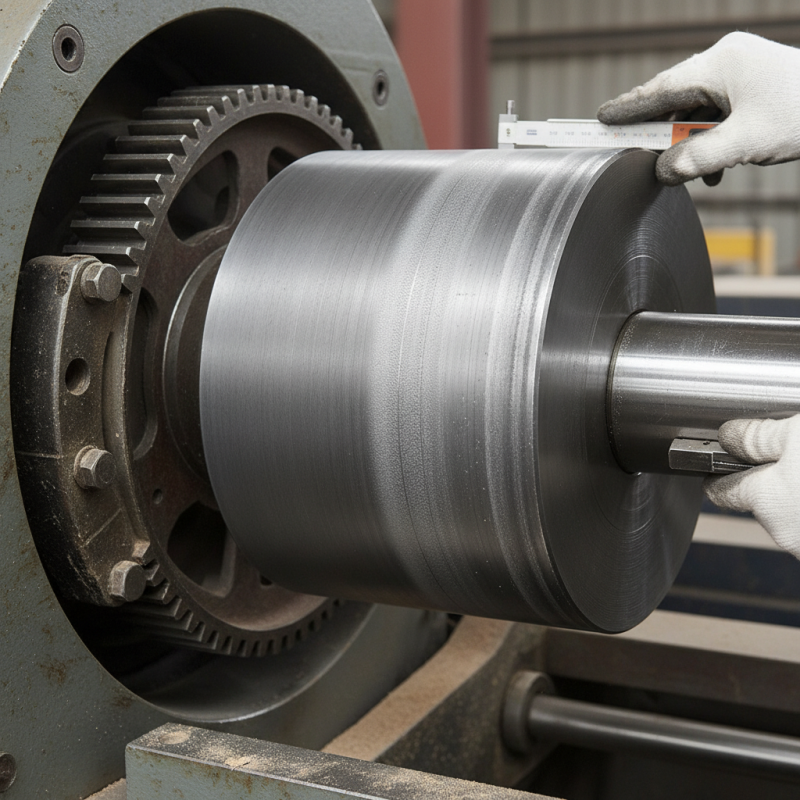

Understanding the specific requirements of your milling operation is crucial. Not all roller sleeves are the same. Material, size, and design can vary significantly. Therefore, selecting the appropriate sleeve for your needs is a decision that requires careful thought. Small adjustments can yield better results. Keeping an open mind about these best practices can lead to improvements over time.

| Dimension | Material | Hardness | Manufacturing Process | Maintenance Frequency | Expected Lifespan |

|---|---|---|---|---|---|

| 100 mm | Steel Alloy | HRC 60 | CNC Machining | Monthly | 3 Years |

| 150 mm | Hard Chrome Plated | HRC 58 | Casting and Grinding | Bi-Monthly | 4 Years |

| 200 mm | Ceramic Coated | HRC 65 | Precision Machining | Quarterly | 5 Years |

| 250 mm | Composite Material | N/A | 3D Printing | Semi-Annually | 5 Years |

Selecting the right material for mill roller sleeves is crucial for optimal performance. According to industry reports, the choice of sleeve material affects wear resistance and lifespan. Materials like polyurethane and ceramic composites show superior durability. These options help reduce downtime and maintenance costs. However, not all mill operations will benefit equally.

Different mills operate under varying conditions. For example, mills with high abrasion levels may experience accelerated wear on softer materials. Engineers often face challenges when balancing flexibility and strength. Polyurethane offers good elongation properties. Yet, in high-stress environments, its performance may decline.

Ceramic composites, while extremely durable, can be brittle. This brittleness could lead to unexpected failures. Choosing the correct material involves understanding specific mill needs. Trials should be conducted to assess performance in real-world scenarios. Data reveals that a tailored approach can improve operational efficiency by up to 25%. Thus, careful consideration is essential for selecting the right roller sleeve material.

Maintaining roller sleeves is vital for optimal performance in milling operations. Regular inspections can help identify wear and tear early. Look for cracks, chips, and uneven surfaces. These issues can lead to reduced efficiency and expensive downtime. Properly cleaning your roller sleeves is essential. Accumulated debris can negatively affect their function.

Lubrication is critical, but it should be done with care. Over-lubricating can attract dirt and lead to premature failure. Applying the right amount of lubricant keeps components functioning smoothly. Consider using a schedule for lubrication to ensure consistency. Monitoring operational parameters can also offer insights into sleeve conditions, prompting timely maintenance actions.

Keep a record of maintenance activities. This practice can highlight patterns or recurring issues. Sometimes, a lack of documentation can mask the need for significant repairs. Such oversights can lead to costly mistakes. Also, involving operators in this process encourages a culture of accountability. They often notice changes before they become big problems. Regular training on roller sleeve maintenance enhances longevity and helps prevent future issues.

Maintaining optimal operating conditions for mill roller sleeves is crucial for efficient performance. The environment affects both durability and functionality. Temperature and humidity levels can impact the material's integrity. Regular monitoring is key.

Tips: Monitor temperature levels consistently. Aim to maintain a range that suits the materials in use. High temperatures can lead to premature wear.

Proper lubrication is essential. It reduces friction and prevents overheating. However, too much or too little can cause issues. Finding the right balance requires testing and adjustments.

Tips: Conduct regular checks on lubrication levels. Observe wear patterns to identify lubrication needs.

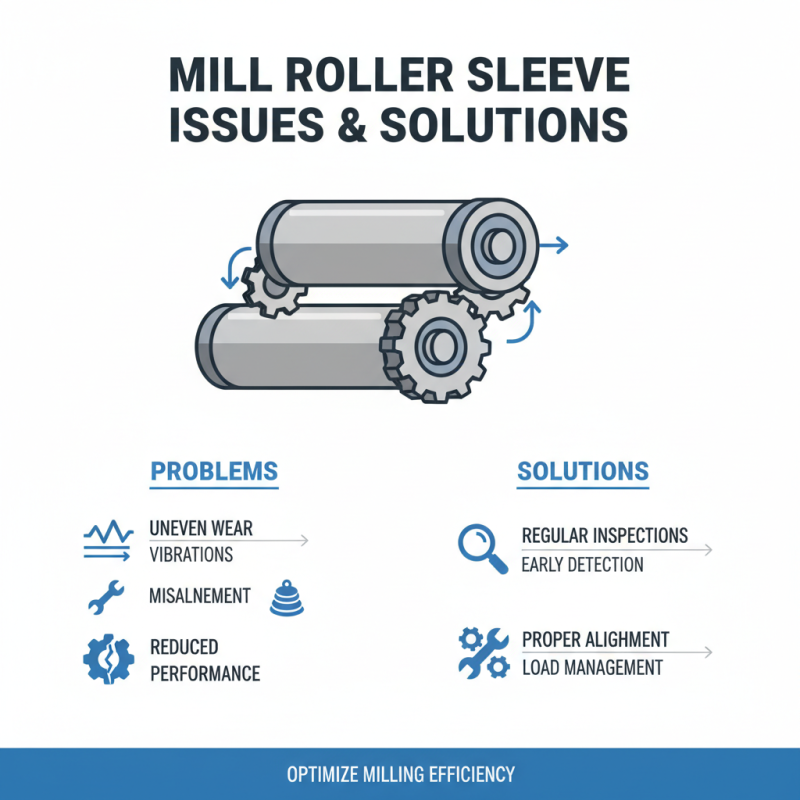

Lastly, ensure alignment of roller sleeves is correct. Misalignment can cause uneven wear and power loss. Frequent inspections help catch misalignment early.

Tips: Invest time in routine alignments. Small adjustments can yield significant improvements.

Mill roller sleeves play a crucial role in the milling process. However, they often face various issues that can affect performance. For instance, uneven wear can lead to vibrations during operation. This may result from misalignment during installation or excessive load on certain sleeves. Regular inspections help identify these problems before they escalate.

Another common issue is contamination from dust and debris. Over time, this can interfere with the sleeve's smooth operation. Regular cleaning protocols are essential to maintain performance standards. Users sometimes overlook the necessity of proper lubrication. Insufficient lubrication can increase friction and lead to overheating. Ignoring these factors can result in costly repairs.

Inadequate maintenance routines can also cause premature failure. Users should document the lifespan of each sleeve for trend analysis. This data can reveal patterns and help in troubleshooting. Engaging in proactive maintenance not only reduces downtime but also enhances efficiency. However, it's crucial to reflect on past mistakes and reassess strategies continuously for ongoing improvement.