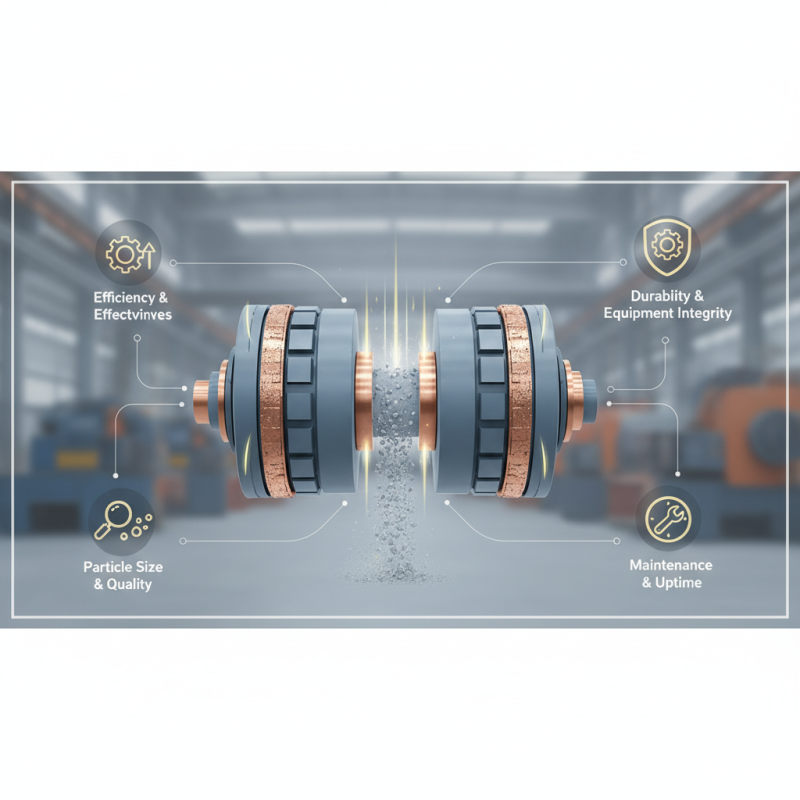

The efficiency and effectiveness of grinding processes in various industrial applications heavily rely on the proper functioning of mill machinery. One crucial component that significantly impacts grinding performance is the Mill Roller Sleeve. These sleeves, designed to fit over the rollers in milling systems, play an essential role in ensuring optimal interaction between the grinding elements and the material being processed.

By providing a stable surface that withstands wear and tear, Mill Roller Sleeves enhance the grinding process while maintaining the overall integrity of the milling equipment. Their material composition and design are fundamental to achieving the desired particle size and quality of the final product. Moreover, regular maintenance and timely replacement of these sleeves can prevent unexpected downtimes and mitigate operational costs, reinforcing their importance in the milling industry.

In summary, understanding the vital role of Mill Roller Sleeves in grinding operations is key for industry professionals aiming to optimize their production processes. The performance, durability, and efficiency of these crucial components are integral to achieving high-quality outputs and maintaining operational excellence in milling applications.

Mill roller sleeves play a critical role in enhancing the efficiency of grinding processes in various industries. These components are designed to provide a smooth surface for the rollers, minimizing friction and wear during operation. By ensuring a tight fit and consistent contact with materials, roller sleeves significantly contribute to maintaining the effectiveness of the grinding process. A well-maintained sleeve can help achieve a finer grind, reducing the energy required for milling and leading to better overall productivity.

In addition to improving grinding efficiency, mill roller sleeves also protect the internal mechanisms of the milling equipment. By acting as a barrier against wear and tear, they extend the lifespan of the rollers and other critical components. This not only reduces the frequency of maintenance and replacements but also optimizes operational uptime. Properly functioning sleeves can help maintain consistent product quality, ensuring that the desired particle size is achieved with each milling cycle. Thus, investing in high-quality mill roller sleeves is essential for any operation aiming for sustained grinding efficiency and performance.

The design and material of mill roller sleeves play a pivotal role in achieving optimal grinding performance. Typically made from high-quality steel or advanced composite materials, these sleeves are engineered to withstand the severe conditions present in grinding operations. According to industry reports, the choice of material can significantly influence wear resistance and overall durability. For instance, sleeves made from hardened steel can increase operational longevity by up to 30% compared to standard alternatives, thus reducing maintenance costs and downtime.

Furthermore, the design of mill roller sleeves allows for effective clearance and alignment during the grinding process. This precision helps in minimizing vibration and enhancing the efficiency of energy usage within the mill. A study by a leading materials science institution highlighted that the right design can enhance grinding efficiency by more than 15%, enabling manufacturers to achieve a finer product with less energy consumption.

**Tips:** When selecting mill roller sleeves, consider the specific material properties and design features that best fit your grinding needs. Regularly inspect and maintain these components to maximize their performance and lifespan. Additionally, investing in quality sleeves can lead to significant long-term cost savings through improved efficiency and reduced wear-related interruptions.

Mill roller sleeves play a crucial role in the grinding process, significantly influencing the particle size distribution of the final product. The design and material composition of these sleeves directly affect the efficiency and effectiveness of the grinding operation. According to a report by the International Journal of Powder Metallurgy, variations in sleeve geometry can lead to changes in the flow of material within the grinding chamber, thereby affecting how materials are crushed and milled. For instance, a study indicates that optimizing roller sleeve surface roughness can decrease the amount of energy required to achieve a specific particle size, which is key for achieving a narrow particle size distribution.

Furthermore, the lifespan and wear resistance of mill roller sleeves are critical parameters that affect grinding consistency. As highlighted in the 2021 Global Grinding Industry Report, worn roller sleeves can lead to increased variability in particle size, as imperfections allow for uneven grinding. It is noted that maintaining mill roller sleeves in optimal condition can result in a more uniform output, enhancing the overall quality of the product. Moreover, proper selection and maintenance of these sleeves may reduce operational costs by minimizing energy consumption, with manufacturers reporting up to a 15% improvement in grinding efficiency when sleeves are regularly assessed and replaced. This emphasizes the importance of mill roller sleeves in achieving desired grinding performance and optimizing particle size distribution.

| Parameter | Description | Impact on Grinding | Recommended Value |

|---|---|---|---|

| Sleeve Material | Material used for roller sleeves | Affects durability and wear resistance | Hard Polyurethane |

| Surface Roughness | Texture of the sleeve surface | Impacts friction and grinding efficiency | Ra < 0.8 μm |

| Sleeve Diameter | Diameter of the roller sleeve | Influences the pressure applied during grinding | Standardized, e.g., 150 mm |

| Operating Speed | Rotation speed of the rollers | Affects particle size reduction rates | 100-200 rpm |

| Pressure Applied | Force exerted on the material | Key factor for achieving desired particle size | 5-10 tons |

Maintaining mill roller sleeves is crucial for ensuring optimal grinding performance and enhancing the durability of milling equipment. Regular inspection is a primary maintenance practice that allows operators to identify wear and tear early. By checking for signs of surface degradation, such as cracks or uneven wear patterns, maintenance teams can take proactive measures to either repair or replace the sleeves before they lead to more significant issues. Implementing a monitoring schedule based on usage rates and operational conditions can help in timely interventions, ultimately extending the lifespan of the sleeves.

Additionally, proper lubrication is essential for minimizing friction and preventing overheating during the grinding process. Using the right lubricant and maintaining clean bearings can significantly reduce wear on the mill roller sleeves. Operators should ensure that the lubrication system is functioning correctly and that levels are topped up as needed. Moreover, employing vibration analysis techniques can provide valuable insights into the operational state of the roller sleeves, helping to predict potential failures and plan maintenance activities effectively. By prioritizing these maintenance practices, businesses can maximize efficiency while minimizing downtime and repair costs.

The wear of mill roller sleeves plays a crucial role in determining the efficiency and productivity of milling operations. As roller sleeves endure continuous friction and mechanical stress during the grinding process, they can develop grooves, cracks, and other types of damage over time. This wear not only affects the sleeves themselves but also has a cascading effect on the overall performance of the milling system.

When sleeves are worn, their ability to interact effectively with the material being processed diminishes. This can lead to uneven grinding, decreased product quality, and increased energy consumption as the mill works harder to achieve the desired output.

Moreover, the wear on roller sleeves can impact the maintenance requirements of the milling equipment. Worn sleeves may cause misalignment of the grinding rollers, contributing to increased operational issues and downtimes. Regular inspection and timely replacement of roller sleeves become essential to maintaining optimal milling performance. By ensuring that roller sleeves are in good condition, operators can minimize disruptions and enhance the reliability of the milling process, ultimately leading to better yield and consistency in product quality. Addressing sleeve wear proactively allows for smoother operations and can significantly improve overall milling efficiency.