In the complex world of energy production, the role of the Power Plant Roller Sleeve stands out. Renowned expert Dr. Emily Carter, a specialist in energy efficiency, emphasizes, "The Power Plant Roller Sleeve is vital for optimizing equipment performance." This seemingly simple component significantly impacts the overall efficiency of power generation.

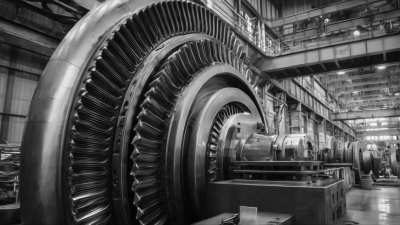

Without a doubt, the Power Plant Roller Sleeve affects how turbines and generators operate. These sleeves absorb vibrations and reduce wear, extending the lifespan of machinery. However, many overlook their importance until issues arise. A poorly maintained sleeve can lead to costly downtimes and repairs, causing ripple effects throughout energy systems.

As energy demands grow, understanding components like the Power Plant Roller Sleeve becomes imperative. It's not just about function but also about reliability and sustainability. Companies must invest in regular assessments and upgrades. A lack of attention can result in inefficient energy production, harming both the economy and the environment.

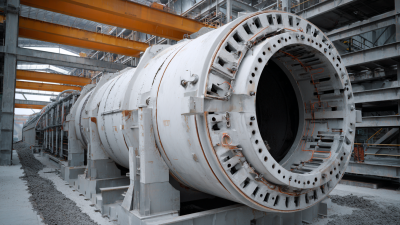

A power plant roller sleeve is a crucial component in energy production. It serves as a protective cover for the rollers found in various equipment, such as turbines and generators. Made from durable materials, it withstands harsh operating conditions. This design helps in reducing wear and tear, prolonging the life of the machinery.

Tips for Maintenance: Regularly check the roller sleeves for signs of wear. Sometimes, small cracks can form unnoticed. Addressing these issues early can save time and costs later.

In addition to protection, roller sleeves ensure smoother operations. They help distribute weight evenly, minimizing vibrations. However, neglecting their maintenance can lead to serious malfunctions. Always keep a close eye on the condition of these sleeves.

Tips for Replacement: When replacing roller sleeves, consider the specifications carefully. Not all sleeves fit every type of machinery. Measure precisely to ensure a correct fit. This small step makes a big difference in efficiency and performance.

The bar chart above illustrates the number of power plants utilizing roller sleeves across five different countries. These components are vital for ensuring the efficient operation of turbines and other equipment in energy production, thereby contributing to the overall reliability and output of power plants.

Roller sleeves are essential components in power plants. They play a critical role in energy production. These sleeves help to support and align various machinery parts. By ensuring optimal alignment, they reduce friction during operations. This function enhances the overall efficiency of power generation systems.

Regular maintenance of roller sleeves is crucial. This can extend their lifespan and improve efficiency. Neglecting them may lead to wear and tear. Such issues can disrupt power generation. It is vital to conduct periodic inspections. Observing for any signs of damage or misalignment can prevent future problems.

Tips: Always monitor the condition of roller sleeves. Look for unusual noises during operation. This can indicate potential issues. Additionally, ensure proper lubrication. Lubrication reduces friction and wear between components. Regular attention can significantly enhance power plant reliability.

Power plant roller sleeves play an essential role in energy production. They ensure smooth operation by supporting rotating shafts. The effectiveness of these sleeves depends largely on the materials used in their manufacturing.

Common materials include carbon steel, stainless steel, and various alloys. Carbon steel offers durability but may corrode over time. Stainless steel is resistant to rust, making it a good choice in harsh environments. Alloys can provide specialized properties like enhanced hardness or thermal resistance. These options reflect the industry's need for strength and longevity.

Manufacturers often face challenges in selecting the right material. Each application may require different attributes. Some materials may not perform well under high temperatures, leading to premature failures. Others can be too expensive for practical use. The quest for the perfect balance continues, as engineers strive to improve efficiency and reliability in energy production.

Power Plant Roller Sleeves play a critical role in energy production. These components are essential for maintaining the efficiency of turbines. In fact, studies indicate that wear and tear on roller sleeves can lead to a significant loss in efficiency. Data shows that even a 10% reduction in efficiency can cost power plants millions in lost revenue.

Reliable operation of roller sleeves is vital for reducing downtime. A failure in this component can halt the entire production process. Reports suggest that unplanned outages cost the industry upwards of $100 billion annually. Regular maintenance and timely replacement of roller sleeves can enhance reliability. Unfortunately, many plants overlook these crucial maintenance schedules.

The right materials for roller sleeves can drastically improve performance. Innovative coatings and designs have shown to extend the lifespan of these components. However, not all plants utilize these advancements. This oversight can result in increased energy costs and environmental impact. Plants must continuously evaluate their equipment to ensure peak performance. The implications of not doing so could be long-lasting in the competitive energy market.

Power plant roller sleeves play a crucial role in energy production. These components support machinery that generates electricity efficiently. Their maintenance is often overlooked, which can lead to significant operational issues. According to industry data, improper maintenance can reduce energy output by 10-15%. Neglect can cause wear and tear, affecting performance and safety.

Regular inspections are essential. They help identify signs of damage early. For instance, monitoring for cracks or surface degradation can prevent catastrophic failures. A report by the Energy Efficiency Agency highlights that a proactive maintenance schedule can improve system reliability by 20%. However, many facilities lack the resources or priorities for this type of upkeep, leading to unfortunate breakdowns.

In practice, maintaining roller sleeves requires balancing time and cost. While some power plants might defer maintenance to save money, this decision often backfires. A lack of upkeep can result in unplanned outages, which are much costlier in the long run. Resources dedicated to maintenance could initially seem high, yet they save downtime costs over time. Balancing short-term savings with long-term reliability is a recurring challenge in the industry.