In the manufacturing industry, the Roll Mill Sleeve plays a crucial role in enhancing the efficiency and precision of processing materials. According to a recent market analysis by Smith & Associates, the demand for Roll Mill Sleeves has grown by over 15% annually, driven by advancements in manufacturing technologies and increased production capacities across various sectors. These components are integral to rolling mills, where they facilitate the smooth operation of the machinery and ensure uniform product quality.

Expert in materials engineering, Dr. Emily Chen, emphasized the importance of the Roll Mill Sleeve by stating, "The performance and longevity of a rolling mill heavily depend on the quality and design of the Roll Mill Sleeve. It acts as the backbone of the process, affecting everything from heat distribution to product consistency." As industries continue to evolve, understanding the functionality of such components becomes vital for manufacturers aiming to optimize their operations and maintain competitive advantage. The insights derived from monitoring the performance of Roll Mill Sleeves can ultimately lead to significant improvements in manufacturing processes, reducing downtime and increasing profitability.

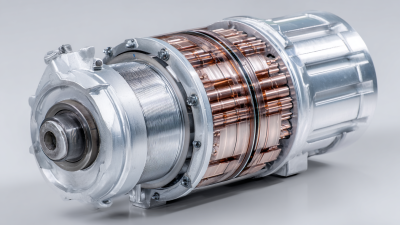

A roll mill sleeve is a critical component in manufacturing processes that involve the reduction of materials and the shaping of products through roller mills. This sleeve, typically constructed from durable materials like steel or high-strength polymers, is designed to fit over the rollers, facilitating the efficient transfer of mechanical forces during the milling process. Roll mill sleeves help in protecting the rollers from wear and tear, thereby prolonging their lifespan and maintaining optimal operational efficiency.

In the context of manufacturing, roll mill sleeves play a significant role in industries such as metalworking, plastics processing, and food production. According to a report by the Global Roll Mill Market, the demand for roll mill equipment, including sleeves, is projected to grow at a compound annual growth rate (CAGR) of 5.2% through 2030. This growth is attributed to the increasing applications of roll milling in producing finer materials and enhancing the quality of end products. By providing a robust protective layer, roll mill sleeves not only reduce maintenance costs but also minimize the risk of contamination, making them indispensable in food-grade applications.

Furthermore, advances in material science have led to the development of innovative roll mill sleeves that offer improved resistance to abrasion and thermal stress. As industries continue to push for higher efficiency and sustainability, the evolution of roll mill sleeves will be crucial in meeting these demands while driving productivity in manufacturing processes across various sectors.

Roll mill sleeves are critical components in the manufacturing processes that utilize rolling mills, particularly in metalworking and plastics industries. Their primary functionality is to serve as a protective layer on the roll surface, enhancing the lifespan of the rolls while ensuring consistent product quality. According to a report by the International Journal of Advanced Manufacturing Technology, the effective use of roll mill sleeves can increase production efficiency by up to 30%, primarily by reducing wear and tear on the rolls and minimizing downtime for maintenance.

In addition to protecting the rolls, roll mill sleeves also play a vital role in optimizing the overall rolling process. They help regulate the thickness and uniformity of the processed materials, contributing to higher product standards. A study published by the Journal of Materials Processing Technology indicates that utilizing high-quality roll mill sleeves can lead to a notable reduction in material defects, thereby decreasing waste and improving the yield rate. This effectiveness positions roll mill sleeves as a crucial factor in achieving operational excellence within manufacturing environments.

Roll mill sleeves are critical components used in various manufacturing processes, particularly in the production of materials like metals and plastics. The effectiveness of roll mill sleeves largely depends on the choice of materials employed in their construction. Generally, high-strength alloys and specialized composites are favored due to their ability to withstand the intense pressure and wear experienced during rolling operations.

Common materials used in the production of roll mill sleeves include carbon steel, which offers excellent tensile strength and durability. Another option is stainless steel, which is resistant to corrosion and maintains its integrity under challenging working conditions. Additionally, advanced polymer materials are also gaining popularity as they provide a good balance of strength, lightweight properties, and resistance to chemicals. The selection of an appropriate material is crucial, as it directly influences the performance, longevity, and efficiency of the manufacturing process, ensuring that the roll mill sleeves can endure the rigors of high-speed operations while maintaining optimal functionality.

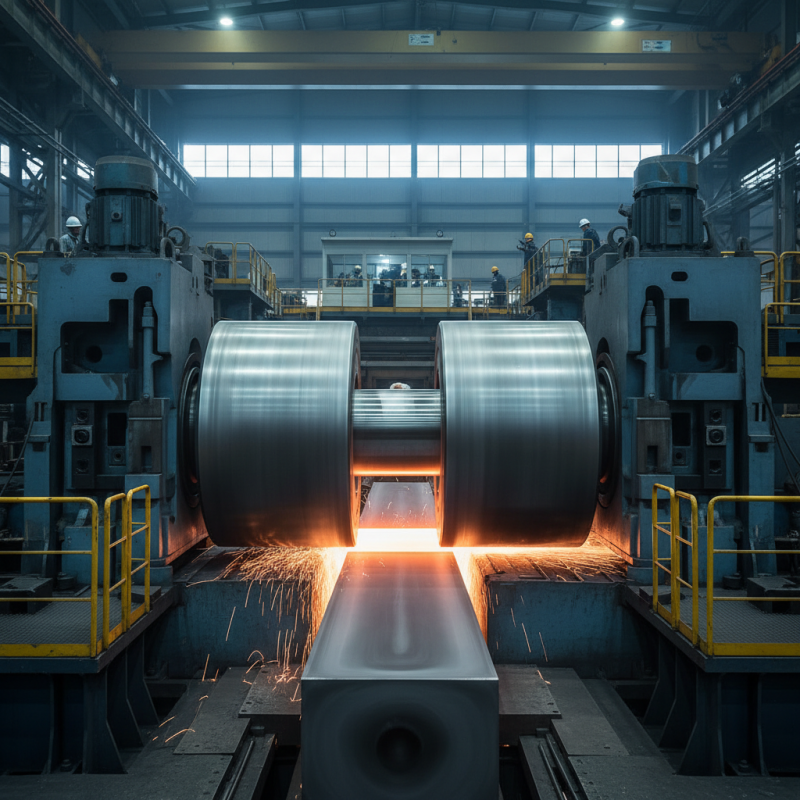

Roll mill sleeves are essential components in various manufacturing processes, primarily used to improve the efficiency and quality of material processing. In the metalworking industry, for instance, roll mill sleeves help in the rolling of metals, allowing for precise thickness and surface finish of the products. The sleeves provide a durable surface that reduces wear and tear on the rollers, thus prolonging their lifespan and enhancing productivity in operations like cold rolling and hot rolling.

In addition to metalworking, roll mill sleeves find applications in the rubber and plastic industries. They play a crucial role in the mixing and refining processes, where consistent and uniform material properties are critical. The sleeves facilitate effective dispersion of additives and other compounds into the base material, ensuring a homogenous mix that meets specific performance criteria. This is vital in producing high-quality rubber products, such as tires and other industrial rubber goods, as well as plastic components that require exact specifications for functionality.

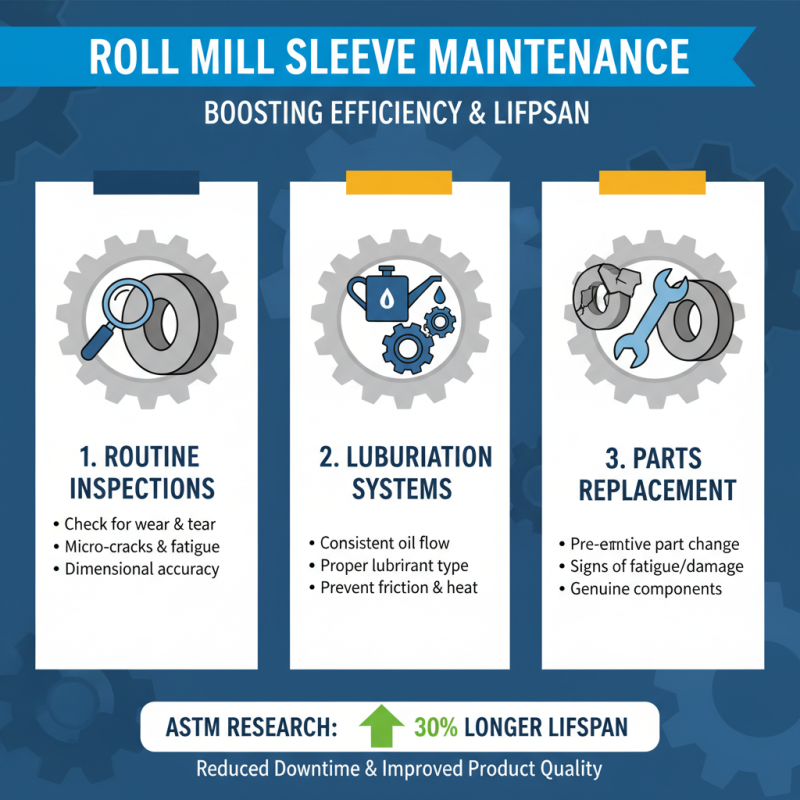

Maintaining roll mill sleeves is crucial to ensuring efficient manufacturing processes, particularly in industries like steel production and plastic processing. Research from the American Society for Testing and Materials (ASTM) indicates that regular maintenance can improve the lifespan of roll mill sleeves by up to 30%. This involves routine inspections for wear and tear, ensuring that lubrication systems are functioning correctly, and replacing parts that show signs of fatigue. Proper maintenance not only helps in minimizing downtime but also enhances product quality by ensuring consistent pressure and temperature during operations.

In addition to standard maintenance, implementing a routine cleaning schedule is vital for optimizing performance. According to data from the International Journal of Manufacturing Science and Engineering, contamination on the surface of roll mill sleeves can lead to surface defects in the final products, resulting in costs that can soar into the millions for large-scale operations. Cleaning intervals should be based on production volumes and the specific type of materials processed. By employing proper cleaning techniques and monitoring wear patterns, manufacturers can significantly reduce unscheduled repair costs and extend the operational efficiency of roll mill sleeves.