Choosing the right centrifugal blower for industrial applications can seem daunting. The global industrial blower market was valued at approximately $8 billion in 2022 and is expected to grow significantly. Centrifugal blowers play a crucial role in various sectors, including wastewater treatment and chemical processing.

Understanding airflow requirements is essential. Proper sizing impacts performance and energy efficiency. Oversized blowers waste energy, while undersized units struggle to meet demand. Data indicates that up to 30% of industrial energy costs can stem from inefficiencies in airflow systems.

Ignoring these factors can lead to operational challenges. Maintenance issues may arise from mismatched blowers. Choosing the right centrifugal blower isn’t just about specifications; it’s about aligning with your unique industrial needs. Evaluating options carefully is key to maximizing efficiency and productivity.

Centrifugal blowers are vital for many industrial applications. They move air and gases efficiently. Understanding their basics is crucial for selecting the right one. Typically, they convert kinetic energy into pressure energy using a rotating impeller. This process generates airflow that is directed outwards.

When choosing a blower, consider the specific requirements of your application. The required airflow rate and static pressure are critical factors. Make sure to look at the noise levels too. Loud blowers can lead to uncomfortable working conditions.

Tips: Always check the efficiency ratings. An efficient blower saves energy and reduces costs. Don't forget to assess the space. Some blowers need more room for installation. Improper fitting can lead to performance issues. Think about future expansion. Will your needs grow? Forward planning can save time and resources.

| Dimension | Value | Notes |

|---|---|---|

| Airflow Rate | 1000 - 10,000 CFM | Depends on application requirements |

| Static Pressure | 5 - 25 in. wg | Higher pressure for more resistance |

| Motor Power | 1 - 250 HP | Based on required airflow and pressure |

| Noise Level | 70 - 85 dB | Consider soundproofing if necessary |

| Efficiency | 70% - 90% | Higher efficiency results in lower energy cost |

| Material | Steel, Stainless Steel, Plastic | Select based on environmental conditions |

Selecting the right centrifugal blower is crucial for industrial applications. Many factors come into play during this decision-making process. Every application has unique requirements, and understanding these is vital. The air volume needed for your operations can affect the blower’s performance. Evaluate the specific airflow requirements thoroughly to avoid issues later.

Pressure is another key factor to consider. The static pressure should match your system requirements closely. A mismatch can lead to inefficiencies, increasing operational costs. Additionally, the blower's efficiency rating impacts performance. Higher efficiency may seem better initially, but it often comes with a higher upfront cost. Balancing costs and efficiency is necessary.

Noise levels cannot be ignored. A quieter blower may improve working conditions. However, quieter models sometimes compromise performance. This trade-off requires careful consideration. Maintenance needs also play a role in the selection process. Many users underestimate the importance of checking these requirements. Regular maintenance ensures longevity and reliable performance. Reflecting on these aspects makes a significant difference in the long run.

When selecting a centrifugal blower, evaluating performance specifications is crucial. Start with airflow requirements. Know the volume of air needed for your processes. This defines the blower's capacity. Underestimating airflow can hinder performance. Overestimating may lead to excess energy use.

Next, consider pressure ratings. Static and dynamic pressure requirements impact the blower's design. Too low a pressure may cause inadequate system performance. On the other hand, excessive pressure can escalate costs unnecessarily. Understand your application’s needs to avoid these pitfalls.

Efficiency is another key factor. Higher efficiency blowers consume less power, providing savings over time. However, achieving optimal efficiency may require a more expensive initial investment. Reflect on the balance between cost and long-term savings. Lastly, don’t overlook noise levels. Industrial environments can amplify sound, affecting operator comfort and compliance. Evaluate noise specifications and your workspace conditions.

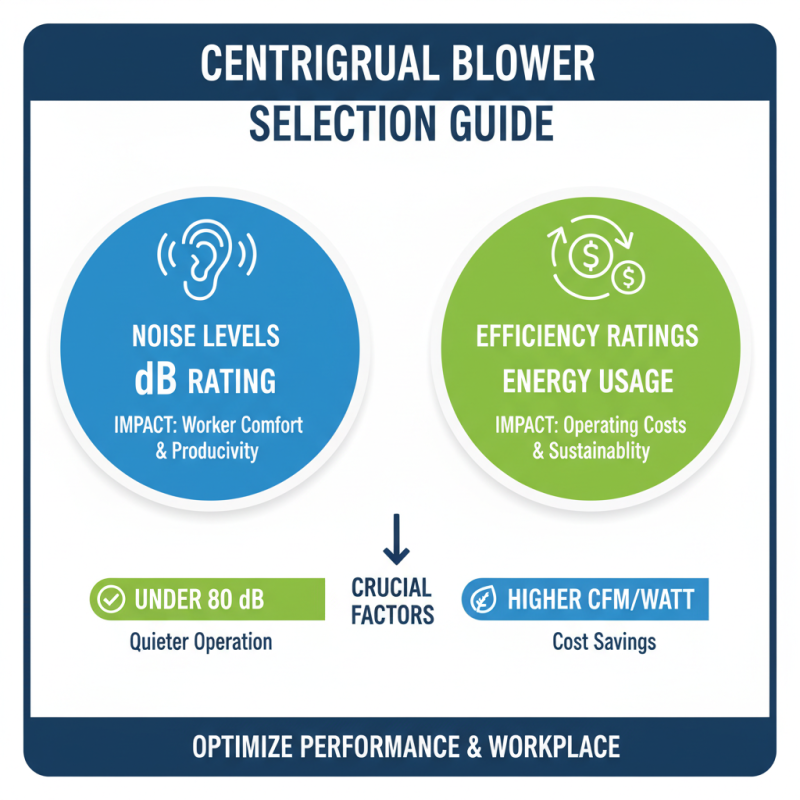

When selecting a centrifugal blower, assessing noise levels and efficiency ratings is key. Noise can impact worker comfort and productivity. This makes understanding dB ratings crucial. Generally, lower dB levels are better. Aim for blowers with noise levels under 80 dB for quieter operations.

Efficiency ratings help determine operational cost. Higher efficiency means lower energy expenses. Look for blowers that provide airflow rates aligned with your needs. Some models may excel in noise reduction but compromise on performance. It's important to balance these factors.

Tips: Always check for certifications. This is often a reliable way to gauge performance. Conduct a visual inspection before purchasing. Look for signs of wear or damage. Reading user reviews can also provide insights into noise and efficiency. Every facility has unique requirements, so consider all aspects carefully. Achieving the right blend of noise and efficiency may take time and effort. Don't rush the decision.

When selecting a centrifugal blower, comparing brands and models is key. Different designs offer varying efficiencies. Studies show that centrifugal blowers can range from 50% to 85% efficiency. The choice affects overall operational costs significantly.

Brand reputation often correlates with performance metrics. However, not all high-rated models are suitable for every industry. For example, specific applications in the food processing sector may require tighter tolerances than those in wastewater management. Evaluating airflow metrics, noise levels, and installation constraints is crucial.

Potential buyers should consider maintenance requirements as well. Some models demand regular servicing, which can add to the total cost. This oversight can lead to expensive repairs down the line. Industry reports indicate that improper selection can result in up to 30% increased energy usage. Hence, understanding brand specifications and user reviews is invaluable for making informed decisions.