In the dynamic landscape of the mining industry, the selection of the right equipment is crucial to operational efficiency and safety. One essential component often overlooked is the "Mining Industry Roller Sleeve." According to industry expert Dr. James Thornton, who has over two decades of experience in mining equipment engineering, “Choosing the correct roller sleeve can significantly minimize maintenance costs and enhance the lifespan of mining machinery.” This statement underscores the importance of making informed decisions in the procurement process.

Roller sleeves serve as vital components within various machinery, facilitating smooth operations in the often harsh mining environment. The durability and compatibility of these sleeves directly influence the overall performance of mining equipment. As the industry continues to evolve, so too does the technology and materials used in roller sleeve manufacturing, making it imperative for mining operations to stay updated on the latest developments. In this article, we will explore essential tips for selecting the right Mining Industry Roller Sleeve, focusing on factors such as material composition, operational conditions, and maintenance requirements to ensure optimal productivity and safety in mining operations.

Roller sleeves are essential components in mining operations, providing a reliable means to transport materials efficiently. They serve as a protective barrier between the moving elements of equipment and the harsh conditions typically found in mining environments. By reducing friction between surfaces, roller sleeves contribute to smoother operations, helping to prolong the lifespan of machinery and minimize downtime due to wear and tear. Their ability to withstand abrasive materials and extreme temperatures makes them a crucial factor in ensuring that mining processes run smoothly and efficiently.

Choosing the right roller sleeve requires a deep understanding of the specific demands of mining activities. Factors such as the type of material being transported, the operating conditions, and the design of the machinery all play a critical role in this selection process. The durability and appropriate material composition of roller sleeves impact not only the performance of the equipment but also the overall efficiency of mining operations. By prioritizing the right roller sleeves, mine operators can enhance productivity, reduce maintenance costs, and ensure a safe working environment for personnel involved in the operations.

Understanding the Importance of Roller Sleeves in Mining Operations

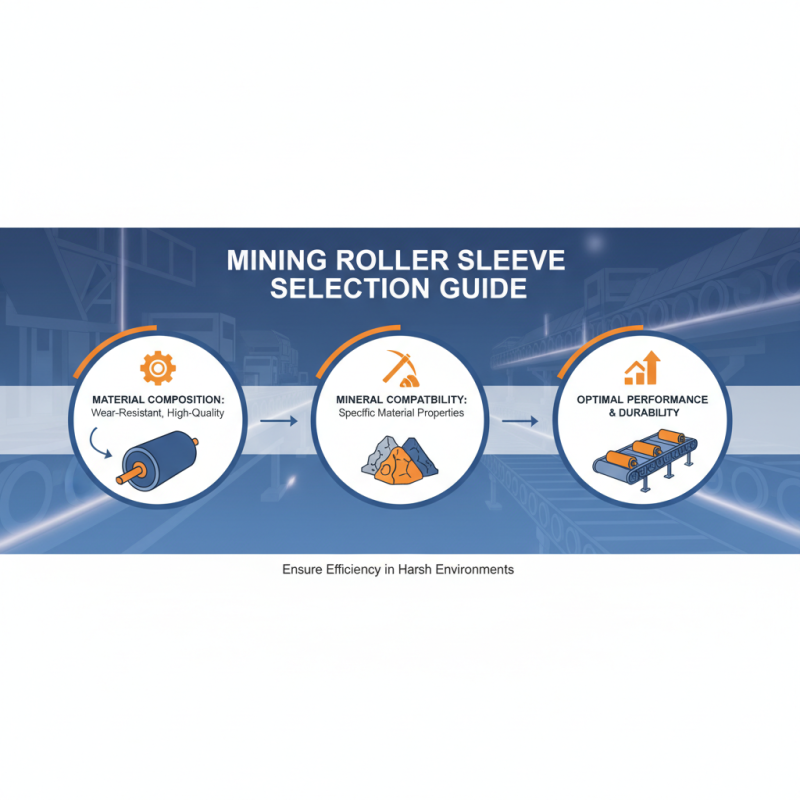

When selecting roller sleeves for the mining industry, it is crucial to consider several key factors to ensure optimal performance and durability. Firstly, the material composition of the roller sleeve plays a significant role in its effectiveness. Sleeves made from high-quality, wear-resistant materials can withstand the harsh conditions commonly found in mining environments, such as exposure to abrasive elements and extreme temperatures. Additionally, the sleeve's compatibility with the type of mineral being mined is essential; selecting a sleeve that can handle the specific properties of the material will enhance the overall efficiency of the operation.

Another important aspect to consider is the size and fit of the roller sleeve. It is essential to ensure that the sleeve fits securely on the roller to prevent slippage and maintain effective operation. Proper sizing can also reduce the risk of premature wear and damage, thereby lengthening the lifespan of both the roller and the sleeve. Furthermore, examining the design and texture of the sleeve can contribute to better performance; for instance, a sleeve with a specific surface texture may improve traction and material handling during mining processes, leading to increased productivity and reduced downtime for maintenance.

When selecting roller sleeves for mining applications, understanding the various types available is crucial to ensure optimal performance and durability. One of the most common types is the foam roller sleeve, recognized for its ability to provide a smooth finish and even coverage on surfaces like ballast or other textured areas. These sleeves are particularly suited for applications involving relatively low viscosity materials, making them an ideal choice for jobs that require precision and efficiency.

Another option is the fabric roller sleeve, which is often made from a blend of fibers designed to withstand abrasive substances common in mining environments. These sleeves excel in applications where heavy-duty performance is necessary, such as when working with dense paints or coatings often used on mining machinery. Additionally, specialist roller sleeves, such as those designed for specific textures or finishes, can be beneficial for more unique mining tasks, allowing for tailored solutions that meet the demands of diverse work scenarios. By carefully evaluating the specific requirements of each application, miners can select the most suitable roller sleeves, ultimately enhancing productivity and reducing maintenance costs.

| Type of Roller Sleeve | Material | Suitable Applications | Advantages |

|---|---|---|---|

| Polyester Roller Sleeve | Polyester Fabric | General Mining Operations | Good durability and wear resistance |

| Nylon Roller Sleeve | Nylon Material | Heavy-Duty Mining Operations | High strength and chemical resistance |

| Foam Roller Sleeve | Foam Material | Surface Applications, Coating | Excellent paint pickup and smooth finish |

| Microfiber Roller Sleeve | Microfiber Fabric | Fine Detailing on Equipment | Superior finish and absorption |

In the mining industry, the selection of the appropriate roller sleeve is critical to ensure both durability and optimal performance in demanding environments. Research indicates that nearly 50% of maintenance costs in mining operations are attributed to wear and tear on machinery components. This underscores the importance of choosing a roller sleeve made from materials that can withstand extreme conditions, such as high temperatures, corrosive substances, and abrasive particles typically found in mining operations.

Materials such as polyurethane and high-quality thermoplastics have been shown to offer superior resistance to wear and allow for better flexibility during operation. According to a recent industry study, roller sleeves composed of these materials can extend service life by up to 30%, reducing downtime and significantly lowering overall operational costs. Furthermore, coatings like ceramic and epoxy can enhance durability by providing an additional shield against physical damage and chemical exposure, further increasing the lifespan of the roller sleeve.

Implementing advanced material technologies not only improves performance but also addresses environmental concerns by minimizing waste through longer-lasting products. With sustainability becoming increasingly important in the mining sector, investing in high-durability roller sleeves contributes to both operational efficiency and environmental responsibility, aligning with industry goals to reduce the ecological footprint of mining activities.

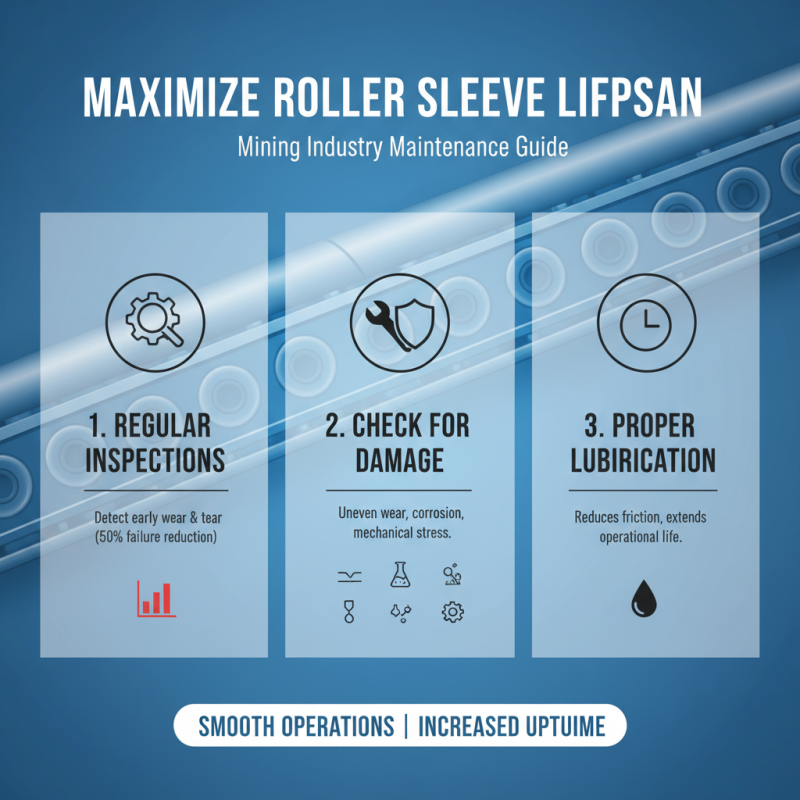

In the mining industry, the longevity and functionality of roller sleeves are critical to ensuring smooth operations. Proper maintenance practices can significantly extend the lifespan of these components. Regular inspections should be a priority; research indicates that approximately 50% of roller sleeve failures stem from wear and tear that could be detected early with routine checks. Look for signs of uneven wear, corrosion, or mechanical damage that could compromise performance.

Tips for prolonging the life of roller sleeves include maintaining optimal lubrication. Studies have shown that inadequate lubrication can lead to a 30% increase in friction and wear, reducing the operational efficiency of the equipment. Using the correct type of lubricant and ensuring that it is applied at appropriate intervals can greatly enhance performance and reduce the likelihood of breakage. Additionally, keeping roller sleeves clean and free of debris can help avoid unnecessary strain.

Another maintenance practice is to adhere to the manufacturer’s recommended operational parameters. Overloading or improper installation can accelerate wear, potentially reducing sleeve lifespan by up to 40%. Training personnel about these parameters and implementing strict compliance can minimize risks. Moreover, consider investing in higher-quality materials designed for durability under extreme conditions, as evidenced by industry reports suggesting that upgraded roller sleeves can outperform standard options by an average of 25% in demanding environments.