Maintaining the performance of mill equipment is crucial for efficiency and productivity in various industrial processes. Among the key components in this machinery, the Mill Roller Sleeve plays a significant role in ensuring smooth operation and optimal output. Despite their importance, these sleeves often face wear and tear due to the rigors of continuous use. As such, understanding how to properly maintain Mill Roller Sleeves becomes essential for operators and maintenance personnel alike.

In this article, we will explore essential tips for maintaining Mill Roller Sleeves to enhance their longevity and performance. Regular inspection, appropriate cleaning methods, and timely replacement are fundamental practices that can drastically reduce downtime and improve overall functionality. By adopting these proactive maintenance strategies, industries can ensure that their milling operations are not only efficient but also cost-effective, thereby maximizing return on investment. Emphasizing the significance of routine care, we aim to provide valuable insights to help operators keep their Mill Roller Sleeves in optimal condition.

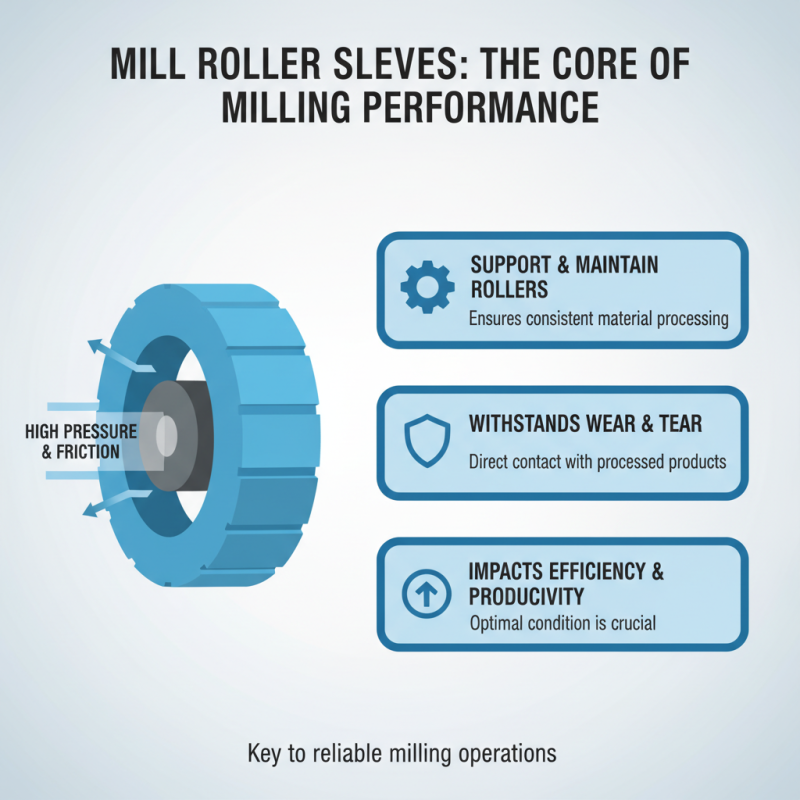

Mill roller sleeves play a crucial role in the overall performance of milling operations. These components are specifically designed to help support and maintain the integrity of rollers, allowing for the consistent processing of materials through a mill. The sleeves bear the brunt of wear and tear, as they are in direct contact with products being processed. Their ability to withstand high pressure and friction directly influences the efficiency of the milling process, making it essential to keep them in optimal condition.

To ensure the longevity and effectiveness of mill roller sleeves, regular maintenance is key. One important tip is to conduct routine inspections to identify any signs of wear, such as scratches or uneven surfaces. Addressing these issues early can prevent further damage and maintain performance levels. Additionally, employing proper lubrication techniques can reduce friction and heat buildup, which are critical for preserving the integrity of the sleeves.

Another essential practice involves adhering to established cleaning protocols. Dust and residue accumulation can hinder the sleeves' functionality, leading to increased operational costs and downtime. Implementing a thorough cleaning schedule will not only extend the life of the sleeves but also enhance the overall productivity of the milling equipment. By understanding the vital role mill roller sleeves play and following these maintenance tips, operators can ensure optimal performance in their milling processes.

Mill roller sleeves play a crucial role in the grinding process, but they often encounter several common issues that can compromise their performance. One prevalent problem is surface wear, which occurs due to prolonged contact with materials being processed. This wear can lead to reduced efficiency and increased energy consumption as the equipment struggles to maintain optimal performance levels. Additionally, improper alignment of the rollers can cause uneven distribution of pressure, resulting in localized damage and reduced lifespan of the sleeves.

Another issue faced with mill roller sleeves is contamination from foreign materials. Dust and debris can accumulate on the sleeves, leading to operational hiccups and potential downtime for cleaning and maintenance. Furthermore, inadequate lubrication can exacerbate friction between the sleeves and rollers, leading to overheating and premature wear. Identifying these causes early on is essential to implement effective maintenance strategies, ensuring that mill roller sleeves operate efficiently and reliably in the long term. Regular inspections and timely interventions can mitigate these issues, preserving both the performance and longevity of the equipment.

Regular inspections of mill roller sleeves are crucial for maintaining their performance and longevity. One effective technique is to conduct visual inspections regularly to check for signs of wear and tear, such as surface cracks or discoloration. These visual cues can provide early indications of impending failures, allowing for timely maintenance before serious issues arise. In addition to visual checks, it’s important to monitor the condition of the bearings and seals around the roller sleeves, as these components are critical in ensuring smooth operation.

Furthermore, utilizing lubrication analysis can significantly enhance the effectiveness of your maintenance routine. Regularly sampling and analyzing the lubricant used in the rollers can help detect contaminations and degradation that may compromise performance. By integrating lubricant analysis into your inspection regimen, you can optimize the maintenance schedule, ensuring that the roller sleeves are receiving adequate protection and minimizing downtime due to unexpected failures.

Incorporating these inspection techniques will not only boost the efficiency of your milling operations but also extend the lifespan of your mill roller sleeves, resulting in better overall productivity. Adopting a proactive approach to maintenance can lead to significant cost savings and improved operational reliability.

Cleaning and maintaining mill roller sleeves is crucial for ensuring optimal performance in any milling operation. To start, always begin with a thorough inspection of the roller sleeves for any signs of wear, damage, or residue buildup. A clean surface is essential for the efficient functioning of the mill, so it’s advisable to remove any accumulated debris using a soft brush or lint-free cloth. Pay particular attention to the areas near the bearings and seals, as these can often trap dirt and particles that lead to premature wear.

Next, employ a suitable cleaning solution, ensuring it is compatible with the materials of the roller sleeves. It's important to apply the cleaning solution evenly, allowing it to penetrate any stubborn residues. After a few minutes, using a soft scrub pad, gently rub the surface to dislodge any remaining deposits, being careful to avoid scratching the sleeves. Rinse thoroughly with water to remove all cleaning agents and dry the sleeves completely to prevent moisture-related issues. Regular maintenance, including proper lubrication as per manufacturer guidelines, ensures the longevity of roller sleeves and maintains optimal milling performance.

| Maintenance Step | Frequency | Tools Required | Additional Notes |

|---|---|---|---|

| Visual Inspection | Daily | None | Check for wear and damage. |

| Cleaning | Weekly | Soft brush, detergent | Ensure all residue is removed. |

| Lubrication | Monthly | Lubricant spray | Apply evenly for smooth operation. |

| Replacement Assessment | Quarterly | None | Determine if replacement is required. |

| Record Keeping | Ongoing | Notebook or software | Log all maintenance activities. |

When it comes to maintaining mill roller sleeves, timely replacement is crucial for ensuring optimal performance. Worn roller sleeves can lead to inefficiencies in production, increased energy consumption, and potential damage to other machinery components. To avoid these issues, operators should adhere to a regular inspection schedule, checking for signs of wear such as grooves, cracks, and surface degradation. Creating a log of these inspections can help in predicting when a replacement might be necessary, allowing for proactive maintenance planning.

Additionally, understanding the indicators that signal the need for replacement is essential. Frequent vibrations, unusual noises during operation, or inconsistent product quality often point to issues with roller sleeves. When any of these symptoms arise, it is advisable to evaluate the condition of the sleeves immediately. Investing in high-quality materials and having a reliable replacement plan in place will not only extend the lifespan of the roller sleeves but also contribute to the overall efficiency of the mill operation. Proper training for personnel on managing these aspects will further enhance operational reliability and productivity.