In an era of increasing energy demands and stricter environmental regulations, the efficiency of power plants has never been more critical. One often overlooked but essential component in the optimization of power generation is the Power Plant Roller Sleeve. These sleeves play a pivotal role in facilitating smooth operation and reducing friction in various plant machinery. According to a report by the International Energy Agency, efficient maintenance and management of such components can lead to a reduction of energy wastage by up to 15%, significantly enhancing overall productivity.

As emphasized by Dr. John Reynolds, a leading expert in power plant operations, "Maintaining the Power Plant Roller Sleeve is crucial not only for maximizing efficiency but also for prolonging the lifespan of the equipment." His insights are supported by industry statistics, which show that regular maintenance can reduce unforeseen downtime by nearly 20%. Consequently, adopting best practices for the upkeep of roller sleeves is essential. By implementing strategic maintenance protocols, power plants can ensure operational excellence while also contributing to sustainable energy production. This article outlines the top ten tips for maintaining Power Plant Roller Sleeves to achieve maximum efficiency and reliability.

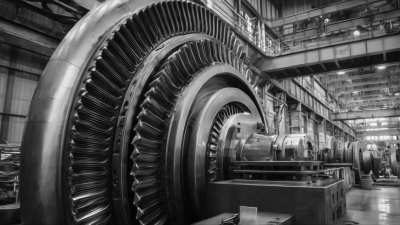

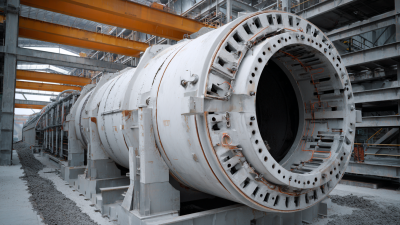

In power plant operations, roller sleeves play a crucial role in ensuring the efficient functioning of machinery. These components act as a protective interface between rotating elements and stationary parts, significantly reducing friction and wear. By facilitating smooth movement, roller sleeves contribute to enhanced performance and object stability within turbines, generators, and conveyor systems, ultimately driving overall plant efficiency. Their reliable operation minimizes downtime and maintenance costs, making them indispensable in the energy sector.

Understanding the material composition and structural design of roller sleeves is vital for optimizing their efficacy. High-quality materials, such as advanced composites or specially treated metals, can withstand extreme conditions, offering both durability and resistance to temperature changes. Regular inspection and maintenance of these sleeves ensure they remain free from damage or degradation, which could lead to operational inefficiencies. Moreover, implementing precise alignment during installation is essential, as misalignment can cause premature wear and reduced performance. As such, prioritizing the maintenance of roller sleeves not only safeguards equipment longevity but also sustains high operational standards in power plants.

| Tip No. | Maintenance Tips | Frequency | Benefits |

|---|---|---|---|

| 1 | Regular Inspections | Monthly | Identifies early wear or damage |

| 2 | Lubrication of Roller Sleeves | Weekly | Reduces friction and wear |

| 3 | Monitoring Operating Temperature | Daily | Prevents overheating |

| 4 | Cleaning Debris from Sleeves | Bi-weekly | Ensures smooth operation |

| 5 | Checking Alignment | Quarterly | Prevents uneven wear |

| 6 | Replacement of Worn Sleeves | As needed | Maintains efficiency |

| 7 | Inspect for Corrosion | Monthly | Prevents structural failure |

| 8 | Vibration Monitoring | Daily | Detects imbalance issues |

| 9 | Seal Integrity Checks | Quarterly | Prevents leaks |

| 10 | Documentation of Maintenance Activities | Ongoing | Tracks history for future reference |

Maintaining power plant roller sleeves is essential for ensuring maximum efficiency and extending the lifespan of the equipment. Regular maintenance practices can significantly reduce wear and tear, which is critical given that studies show that improper maintenance can lead to a 5-15% decrease in operational efficiency. Best practices include conducting routine visual inspections to identify any signs of wear, such as cracks or surface degradation, which can lead to costly downtimes if not addressed promptly.

Another effective practice is to implement a systematic cleaning schedule. Accumulation of debris and contaminants can lead to operational inefficiencies and increased friction between components. It's recommended to clean roller sleeves at least once every quarter, depending on the operational environment. Additionally, lubrication plays a crucial role in maintaining roller sleeve functionality. Using high-performance lubricants can reduce friction and wear, effectively extending the lifespan of these components by 20-30% according to industry reports.

Ultimately, training staff on proper maintenance protocols is vital. Having knowledgeable personnel ensures that all maintenance tasks are performed consistently and comprehensively. Regular workshops and refresher courses can improve overall staff performance, leading to better preventive measures and quicker identification of issues. By adhering to these essential maintenance practices, power plants can optimize the performance of roller sleeves and enhance overall plant efficiency.

Maintaining roller sleeves in power plants is critical for ensuring efficient operation, yet several common challenges can hinder this process. One frequent issue is wear and tear due to prolonged exposure to harsh environmental conditions and high operating loads. This degradation can lead to misalignment and reduced performance. To combat this, regular inspection schedules should be established to monitor wear patterns and promptly address any discrepancies before they develop into more severe problems.

Another challenge is the accumulation of debris and contaminants that can impair the roller sleeves’ functionality. This buildup can result from operational factors, such as dust and particulate matter in the air, or from the lubricants used. Implementing effective cleaning protocols and utilizing protective covers can significantly reduce the ingress of harmful materials. Additionally, integrating advanced monitoring technologies such as vibration analysis can help in identifying unusual patterns that may indicate underlying issues, allowing for timely intervention and ultimately enhancing the efficiency and lifespan of roller sleeves.

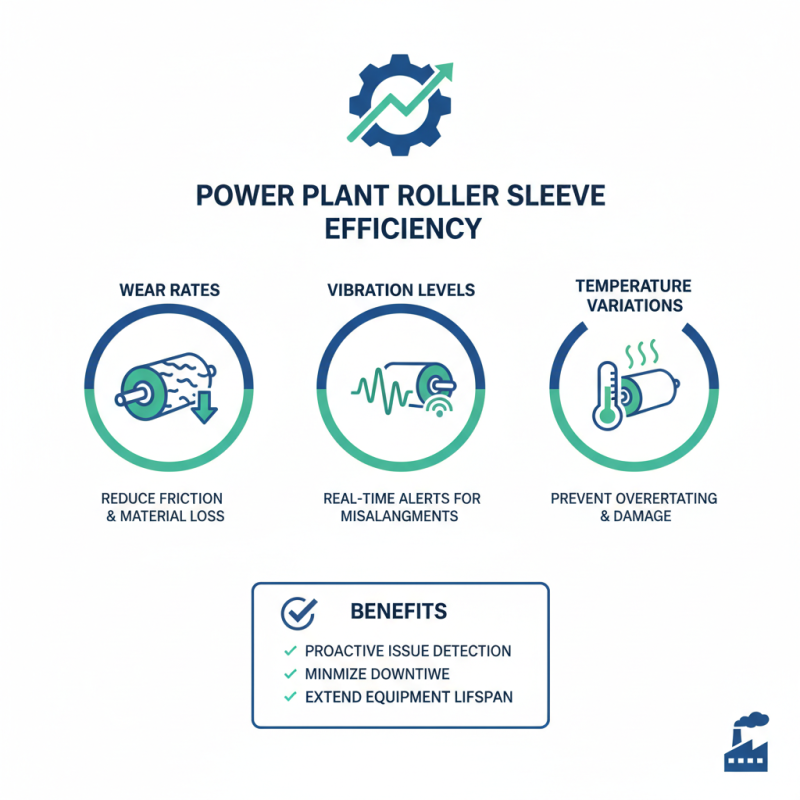

Monitoring performance metrics is crucial for enhancing the efficiency of power plant roller sleeves. Regularly assessing key indicators such as wear rates, vibration levels, and temperature variations allows operators to identify potential issues before they lead to costly downtime. For instance, implementing a vibration monitoring system can provide real-time data, alerting technicians to misalignments or abnormalities that may compromise the functionality of the roller sleeves.

Moreover, tracking operational efficiency metrics can also guide maintenance schedules and strategies. By analyzing historical performance data, operators can develop predictive maintenance plans that align with the specific wear patterns and operational environments of their roller sleeves. This proactive approach not only reduces unplanned maintenance but also extends the lifespan of the components, ultimately leading to enhanced productivity and reduced operational costs. Regular reviews of these performance metrics create a feedback loop that continuously improves the maintenance processes and operational strategies in place.

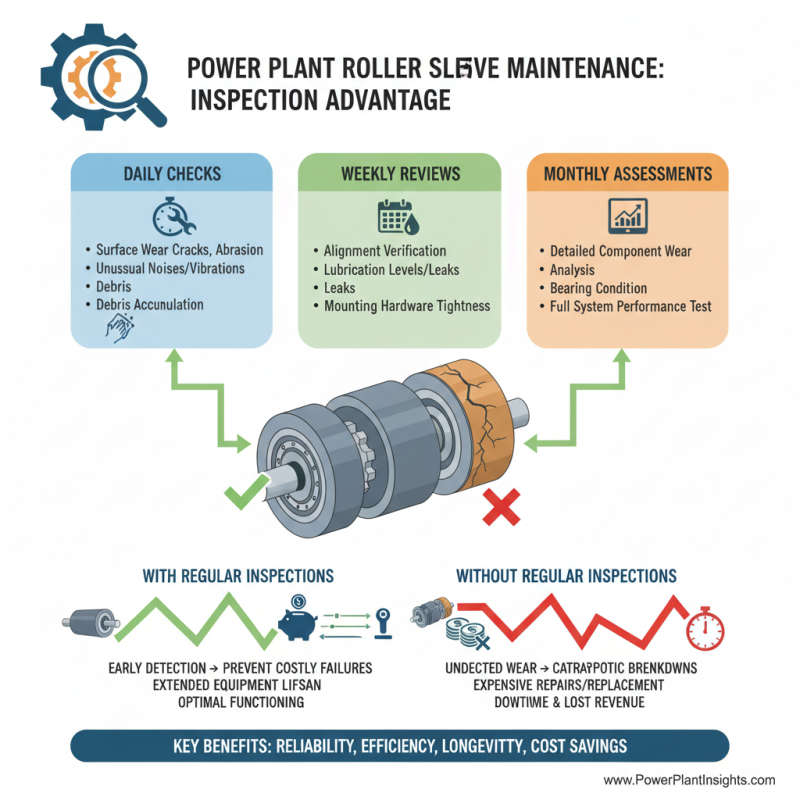

Implementing a regular inspection schedule is vital for ensuring the optimal functioning of power plant roller sleeves. Routine checks allow for the early detection of wear and tear, preventing costly failures and extending the lifespan of the equipment. By establishing a timeline that includes daily, weekly, and monthly inspections, plant operators can systematically assess the condition of the roller sleeves. Key areas to examine include surface wear, alignment, and lubrication levels, as these factors significantly affect efficiency.

Additionally, incorporating predictive maintenance techniques can enhance the effectiveness of the inspection schedule. Utilizing advanced technologies such as vibration analysis and thermal imaging can provide deeper insights into potential issues before they escalate. This proactive approach not only helps in maintaining efficiency but also minimizes unexpected downtimes, allowing the plant to operate at peak performance. Overall, a strategic inspection regimen fosters reliability and operational excellence in power plant operations.