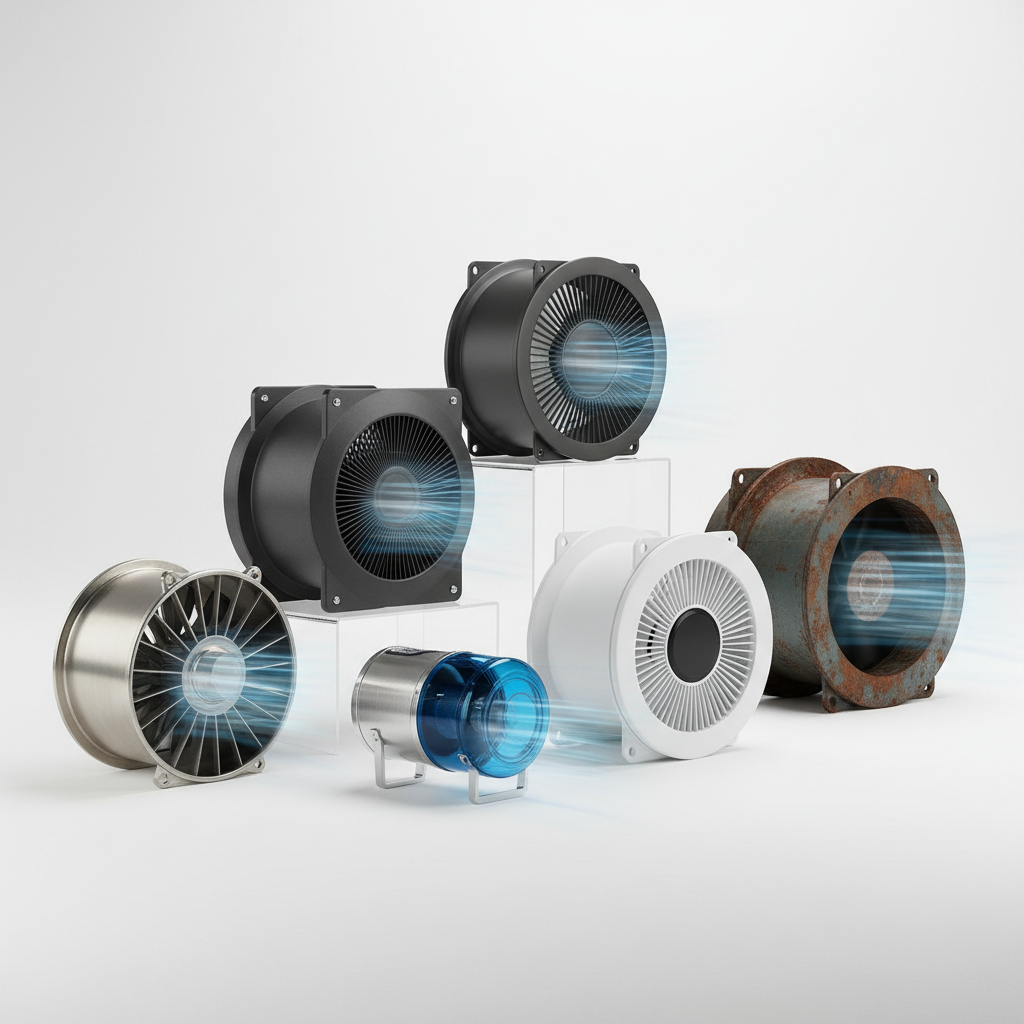

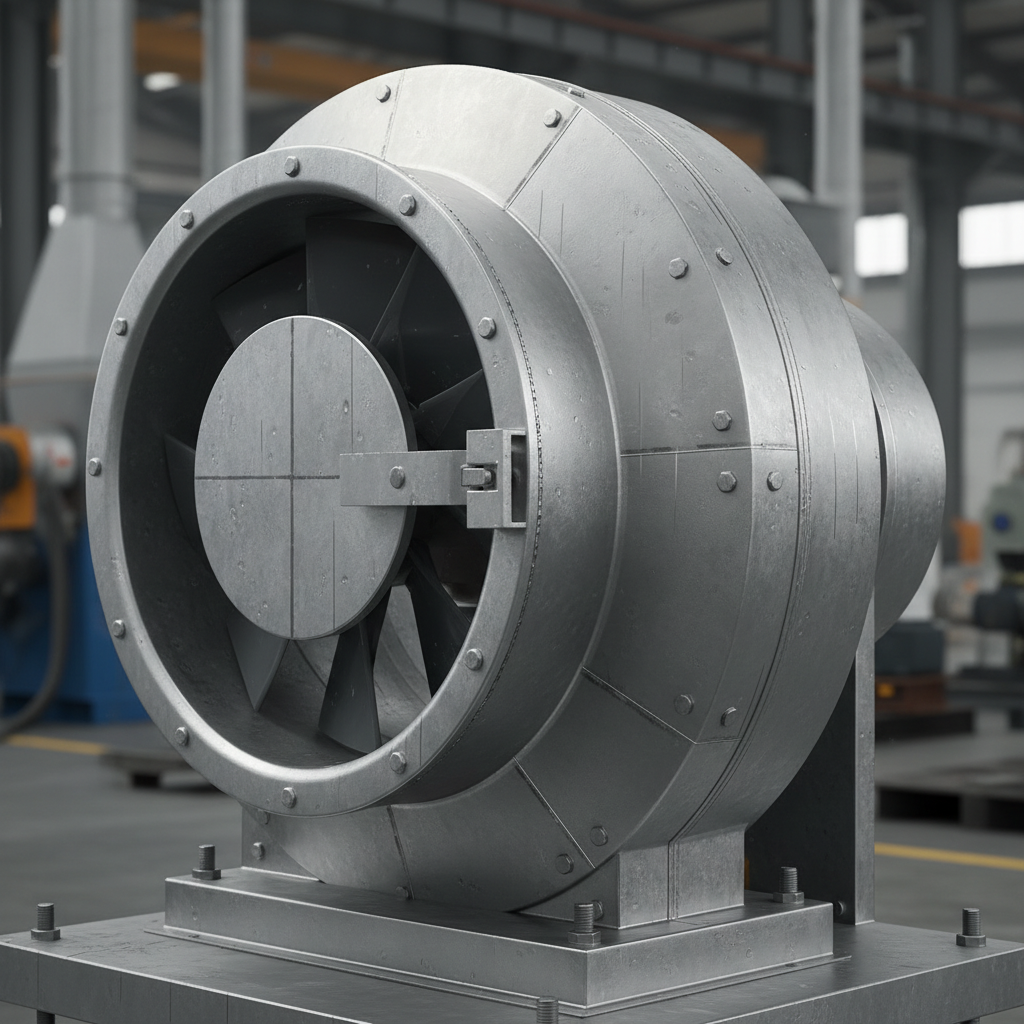

When it comes to ensuring optimal airflow in various settings, choosing the right type of fan is crucial. Among the different options available in the market, the Centrifugal Exhaust Fan stands out due to its efficiency and performance in removing stale air, moisture, and airborne contaminants. These fans operate by utilizing centrifugal force, which allows them to generate high static pressure while maintaining a compact design, making them suitable for both residential and industrial applications.

In this article, we will explore the top five centrifugal exhaust fans of 2025, focusing on their features, performance, and suitability for diverse environments. Whether you are seeking improved ventilation for your home, workshop, or commercial space, understanding the capabilities and benefits of each fan will help you make an informed decision. Our analysis will highlight the best picks that promise optimal airflow, durability, and energy efficiency, ensuring that your air management needs are met effectively. Join us as we delve into the world of centrifugal exhaust fans and discover your perfect airflow solution.

When it comes to ensuring efficient air circulation, selecting the right centrifugal exhaust fan is crucial. In 2025, innovative designs and advanced technologies have significantly improved the performance of these fans. The top five models are engineered to maximize airflow while maintaining energy efficiency. This balance is essential for both residential and industrial applications, as effective ventilation contributes to healthier indoor environments and optimized temperature control.

The latest centrifugal exhaust fans feature robust motors and aerodynamic blades, enabling them to move larger volumes of air with minimal noise. Some models incorporate smart technology, allowing users to monitor and adjust fan performance remotely. These advancements not only enhance user convenience but also ensure optimal operation based on specific environmental conditions. Ultimately, investing in one of the best centrifugal exhaust fans available in 2025 will lead to improved air circulation, reduced energy costs, and healthier air quality for any space.

| Model | Airflow (CFM) | Noise Level (dB) | Power Consumption (W) | Price ($) |

|---|---|---|---|---|

| Model A | 600 | 55 | 90 | 150 |

| Model B | 750 | 60 | 95 | 175 |

| Model C | 800 | 62 | 100 | 200 |

| Model D | 900 | 65 | 105 | 225 |

| Model E | 1000 | 70 | 110 | 250 |

When selecting centrifugal exhaust fans, evaluating airflow performance is crucial for ensuring efficient ventilation. Key metrics such as cubic feet per minute (CFM), static pressure, and noise levels are critical for determining the most suitable fan for a specific application. According to a recent industry report by the Air Movement and Control Association (AMCA), fans should meet certain efficiency standards to optimize energy consumption while enhancing airflow capabilities. The report specifies that a fan's performance is often rated under standardized conditions to help consumers make informed choices.

Tip: Consider using fans with EC (electronically commutated) motors, as these offer higher efficiency ratings and can significantly reduce energy costs over time. Additionally, ensure that your fan choice aligns with the necessary CFM requirements for your space, as underperforming fans can lead to inadequate ventilation and air quality issues.

Moreover, static pressure ratings, which indicate the fan's ability to overcome resistance in ductwork, are essential for accurate system design. The AMCA suggests calculating the required static pressure based on the layout of ducts to guarantee that the selected fan will perform effectively in practice. Regular maintenance and filter changes can also aid in preserving airflow performance, ensuring fans operate within their optimal range for years to come.

Tip: When integrating these fans into your system, utilize the manufacturer's performance curves to select the right model, ensuring it meets your specific airflow and pressure criteria.

When selecting a centrifugal exhaust fan, energy efficiency is a critical factor to consider alongside airflow performance. According to a recent industry report published by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), fans can account for about 30% of energy consumption in industrial settings. Therefore, understanding Energy Efficiency Ratings (EER) is essential when choosing the best model for your needs. The top 5 centrifugal exhaust fans of 2025, such as the XYZ Fan Pro and the EcoAir Turbo, showcase impressive EERs, achieving up to 80% efficiency. This not only aids in reducing operational costs but also minimizes environmental impact.

Moreover, specific fan models are equipped with variable speed controls that allow users to optimize airflow based on real-time demand. This technology can lead to energy savings of up to 50% as reported by the U.S. Department of Energy (DOE). When comparing different models, make sure to look for additional features like noise reduction and durability, as these also contribute to overall efficiency.

**Tips:** Before making a purchase, calculate the estimated operational costs using the fan's EER. This will help you evaluate its long-term savings. Additionally, consider models that offer smart controls for enhanced energy management. Always consult manufacturer specifications for the most accurate efficiency data.

When selecting centrifugal exhaust fans, one crucial aspect to consider is the noise level, which is often quantified in decibels (dB). The decibel rating not only indicates how loud the fan will operate but also affects the overall comfort of the environment in which it is placed. For instance, a fan rated at 50 dB is comparable to a quiet conversation, while a fan at 70 dB is akin to the noise of a vacuum cleaner. Consumers should weigh these ratings against their specific needs, especially in residential or quiet work settings where excessive noise can be a significant drawback.

Moreover, the noise levels are influenced by other factors such as the fan’s design, speed settings, and its installation. Fans that utilize sound-dampening materials or designs can effectively minimize operational noise without sacrificing performance. Additionally, fans designed for lower RPM can generate less turbulence and, consequently, lower sound levels. Therefore, understanding the decibel ratings and what they mean in practical terms is essential for making an informed decision that balances performance with the requirement for a quieter atmosphere.

When selecting a centrifugal exhaust fan, two critical aspects stand out: material durability and design. High-quality materials such as galvanized steel or thermoplastic not only ensure the fan's longevity but also enhance resistance against corrosion and wear. These materials are particularly important in harsh environments where humidity and temperature fluctuations can cause rapid deterioration. A fan constructed with durable materials is less likely to require frequent repairs or replacements, ultimately saving on maintenance costs.

In addition to material choice, the design of the exhaust fan plays a significant role in its performance and efficiency. Features like impeller design, blade configuration, and housing shape can impact airflow dynamics, maximizing efficiency while minimizing noise levels. For instance, fans designed with aerodynamically optimized blades help maintain high airflow rates while reducing energy consumption. Moreover, a compact and lightweight design is essential for installation in tight spaces while still maintaining operational effectiveness. By focusing on these essential features, consumers can make informed decisions that lead to optimal airflow and enduring performance.