In the rapidly evolving field of industrial blowers, the Air Suspension Centrifugal Blower stands out for its unique ability to deliver high efficiency and reduced operational noise. According to renowned engineer and industry expert, Dr. Emily Carter, "The true potential of the Air Suspension Centrifugal Blower lies in its innovative design, which allows for both energy savings and enhanced performance." Her insights highlight the critical role these blowers play in various applications, from manufacturing facilities to wastewater treatment plants.

The growing demand for sustainable and efficient technologies has made the Air Suspension Centrifugal Blower a preferred choice among engineers and operators alike. With their advanced technology, these blowers provide numerous benefits, including better airflow control, lower maintenance needs, and extended equipment lifespan. This introduction to the top 10 Air Suspension Centrifugal Blowers will explore their features, advantages, and practical tips for implementation, ensuring you’re equipped with all the knowledge you need to make informed decisions in this competitive market.

As we delve into the specifics of these blowers, it's essential to appreciate their impact on operational efficiency and energy consumption. By integrating the right Air Suspension Centrifugal Blower into your systems, you can significantly enhance performance while contributing to a greener future.

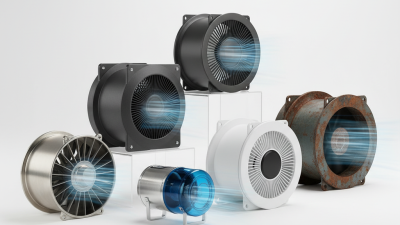

Air suspension centrifugal blowers are essential tools in various industrial applications, providing efficient airflow and pressure consistency. When selecting a blower, it's crucial to understand the key features that ensure optimal performance. One of the most significant features is the airflow capacity, which determines the volume of air the blower can move within a given time frame. Additionally, the design of the impeller affects the blower's efficiency and noise levels. Look for models with adjustable speed settings to tailor the airflow to specific needs, maximizing efficiency while minimizing energy consumption.

Another important aspect is the material quality of the blower. Durable materials like stainless steel or high-grade plastics can greatly enhance the longevity of the equipment. Furthermore, pay attention to the ease of maintenance; blowers with accessible components will save time and effort during service.

Tips for choosing the right blower include evaluating your specific application requirements. Consider the environment in which the blower will operate, as features like vibration dampening may be necessary for quieter functions. It's also wise to compare the warranty and support options offered, as reliable customer service can make a significant difference in troubleshooting and repairs. By keeping these tips in mind, you can ensure a more informed and successful purchase.

| Model | Airflow (CFM) | Pressure (inHg) | Power (HP) | Weight (lbs) | Efficiency (%) | Noise Level (dB) |

|---|---|---|---|---|---|---|

| Model A | 2000 | 10 | 5 | 150 | 85 | 70 |

| Model B | 1800 | 9 | 4 | 140 | 80 | 75 |

| Model C | 2500 | 12 | 6 | 160 | 88 | 68 |

| Model D | 2200 | 11 | 5.5 | 155 | 86 | 72 |

| Model E | 2100 | 10.5 | 5.5 | 150 | 87 | 71 |

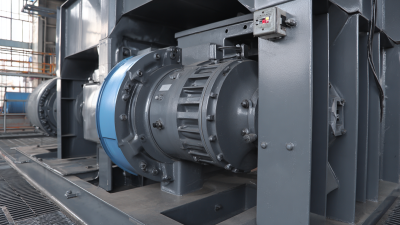

Air suspension centrifugal blowers are essential tools in various industries, offering several key benefits that enhance operational efficiency and product quality. Unlike traditional blower systems, these blowers utilize air suspension technology, which allows for smoother operation and reduced vibration. This results in lower noise levels and improved reliability, making them an ideal choice for environments where sound control is crucial.

One of the primary advantages of air suspension centrifugal blowers is their energy efficiency. By minimizing mechanical friction and offering a lightweight design, these blowers consume less power while delivering consistent airflow. This energy savings translates to reduced operational costs over time, making them an attractive option for companies looking to optimize their bottom line.

When considering the adoption of air suspension centrifugal blowers, here are a few tips to enhance performance. Firstly, regular maintenance is key—ensure that all components are clean and well-lubricated to prevent wear and prolonged downtime. Secondly, evaluate the blower's setup to confirm it meets the specific requirements of your application. This includes airflow needs and pressure specifications, which can significantly impact efficiency. Finally, investing in high-quality installation will ensure that the blowers operate at their peak for years to come, providing lasting benefits to your industrial processes.

When comparing air suspension centrifugal blowers to traditional blowers, a few key performance factors come into play. Air suspension blowers utilize a flexible design that allows for a more cushioned operation, which reduces the impact of vibrations and noise during use. This design leads to improved energy efficiency, as the blowers can operate at various capacities without the loss of performance, adapting seamlessly to different demands while minimizing energy consumption.

In contrast, traditional blowers often have fixed components that can lead to wear and tear over time, resulting in decreased efficiency and higher operational costs. The rigidity of their design typically results in more consistent but less flexible performance. While traditional blowers may excel in specific applications due to their straightforward mechanics, air suspension blowers offer greater versatility across diverse environments, making them suitable for various industries where dynamic airflow requirements are necessary. By reducing wear and tear and enabling smoother operation, air suspension blowers can ultimately extend service life and enhance overall productivity.

Air suspension centrifugal blowers are essential in various industrial applications, offering significant benefits such as improved efficiency and reduced vibration. However, to maximize their lifespan, proper maintenance is crucial. Regular inspection of critical components, such as the impeller and bearings, helps identify potential issues before they escalate. According to a report by the International Energy Agency (IEA), optimal maintenance practices can enhance equipment longevity by up to 25%, directly impacting operational costs and energy efficiency.

One effective maintenance strategy involves consistent cleaning of the blower’s inlet and outlet paths to prevent the accumulation of debris, which can hinder airflow and lead to motor strain. Additionally, lubricating moving parts is vital, as friction increases wear and tear. The ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers) suggests that maintaining proper lubrication intervals can reduce mechanical failure rates by as much as 30%. By following these proactive maintenance tips, facilities can ensure their air suspension centrifugal blowers operate efficiently and have a significantly extended operational life.

This chart displays the airflow capacity of the top 10 air suspension centrifugal blowers. Each blower provides different airflow measured in cubic feet per minute (CFM), highlighting their performance for potential users.

Air suspension centrifugal blowers are increasingly recognized for their versatility and effectiveness across various industrial applications. One prominent area where they excel is in pneumatic conveying systems. Their ability to generate a consistent and robust airflow makes them ideal for transporting bulk materials such as powders, granules, and pellets over long distances. This capability is crucial in industries like food processing, pharmaceuticals, and plastics, where maintaining product integrity during transportation is vital.

In addition to pneumatic conveying, air suspension centrifugal blowers are also widely used in ventilation and air handling systems. Their design allows for quiet operation and efficient airflow, making them suitable for environments that require high air quality and minimal noise, such as hospitals and laboratories. Moreover, their adjustable airflow can be tailored to specific needs, enhancing energy efficiency and reducing operational costs. This versatility extends to various sectors, including manufacturing and wastewater treatment, where reliable ventilation is essential for maintaining operational safety and efficiency.