In the ever-evolving landscape of electric motors, PM Synchronous Motors stand out as a testament to modern engineering and innovation. These motors are not just efficient; they represent a significant advancement in technology that combines high performance with sustainability. Dr. Jane Smith, a leading expert in motor technology, once remarked, “The transition to PM Synchronous Motors is not only about improving efficiency but also about embracing a smarter approach to energy consumption.” This insight encapsulates the essence of what makes these motors an attractive choice for various applications, from industrial processes to electric vehicles.

As industries strive for greater sustainability and efficiency, understanding the nuances of PM Synchronous Motors becomes increasingly crucial. With their ability to maintain a constant speed regardless of load variations, these motors are paving the way for enhanced operational effectiveness. This comprehensive guide will explore the top five benefits of PM Synchronous Motors, highlighting innovations that further unlock their potential in diverse sectors. By delving into their operational principles, efficiency metrics, and real-world applications, we aim to equip engineers and decision-makers with the knowledge to harness the full power of PM Synchronous Motors, driving forward a new era of energy-efficient solutions.

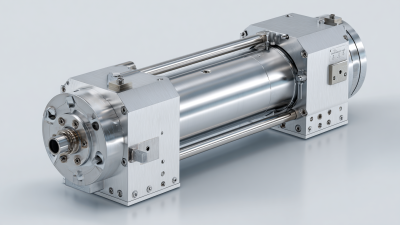

Permanent Magnet (PM) Synchronous Motors (PMSMs) have gained popularity in various industrial applications due to their efficiency and reliability. Characterized by their use of permanent magnets embedded in the rotor, these motors offer exceptional performance compared to traditional induction motors. One of the key features of PMSMs is their ability to maintain constant speed under varying load conditions, making them ideal for applications that require precise speed control.

Tips: When selecting a PM Synchronous Motor for your application, consider the required torque and speed characteristics. Ensure that the motor's specifications align with your system's demands to achieve optimal performance.

Additionally, PMSMs are known for their low maintenance needs and improved energy efficiency, thanks to reduced heat generation and higher power factor. Their compact design also allows for easy integration into existing systems. Understanding the operational principles of these motors can help engineers make informed decisions about their use in automation, robotics, and renewable energy systems.

Tips: Regular monitoring of motor performance can help identify potential issues before they lead to failures. Implementing predictive maintenance strategies can further enhance the longevity and efficiency of your PMSM systems.

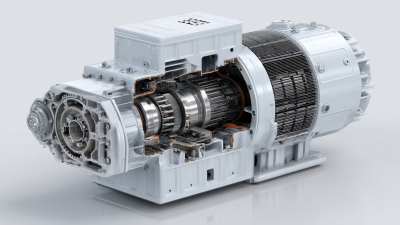

Permanent Magnet Synchronous Motors (PMSMs) have become essential in various industries due to their remarkable efficiency and performance characteristics. According to the International Electrotechnical Commission (IEC), PMSMs can reach efficiency levels between 90% to 95%, significantly higher than traditional induction motors, which typically operate around 70% to 90%. This enhanced efficiency is attributed to the absence of rotor losses, as the rotor is magnetized by permanent magnets rather than induced currents. Consequently, industries are increasingly shifting towards PMSMs to reduce operational costs and minimize energy consumption.

Furthermore, the adoption of PMSMs plays a crucial role in achieving sustainability targets. The U.S. Department of Energy reports that implementing energy-efficient motors, including PMSMs, could reduce energy consumption in the industrial sector by approximately 25%. Additionally, as companies strive to meet stringent environmental regulations, PMSMs are favored for their lower carbon footprint compared to conventional motors. As innovations in material science continue to improve the magnetic properties and manufacturing processes of these motors, their application in energy efficiency will only increase, positioning them as a cornerstone in the future of industrial automation and electric mobility.

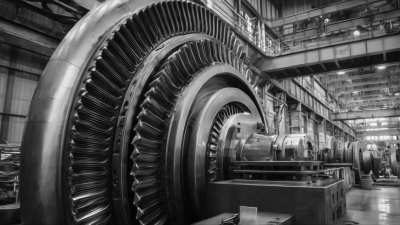

Permanent magnet synchronous motors (PMSMs) are becoming increasingly significant across various industries, driven by their high efficiency and innovative applications. With the electric vehicle market projected to grow exponentially, PMSMs are playing a critical role in enhancing motor performance, offering high torque density and compact designs. Industries like automotive, aerospace, and renewable energy are leveraging these motors to boost operational efficiency and reduce environmental impact.

**Tips**: When considering PMSMs for industrial applications, focus on integrating smart technology to monitor performance in real-time. This approach will not only improve maintenance strategies but also optimize energy consumption. Additionally, invest in training programs for your workforce to ensure they are equipped with the necessary skills to work with these advanced systems.

Another exciting application is the proliferation of PMSMs in electric buses, transforming urban transport. These motors contribute to cleaner emissions and reduce noise pollution, making cities more livable. The growth trajectory of PMSMs in such sectors illustrates their versatility and the ongoing shift towards sustainable solutions in a variety of contexts.

**Tips**: Explore partnerships with technology providers to adopt advanced motor control strategies. This can enhance the efficiency of PMSMs, particularly in demanding applications like public transport, where reliability and performance are paramount.

| Industry | Application | Efficiency (%) | Innovation Aspect | Case Study Reference |

|---|---|---|---|---|

| Automotive | Electric Vehicles | 90 | Regenerative Braking | Case Study A |

| Manufacturing | Conveyor Systems | 85 | Energy Recovery | Case Study B |

| Aerospace | Aircraft Propulsion | 92 | Lightweight Design | Case Study C |

| HVAC | Variable Speed Drives | 88 | Smart Control Systems | Case Study D |

| Renewable Energy | Wind Turbines | 93 | Grid Integration | Case Study E |

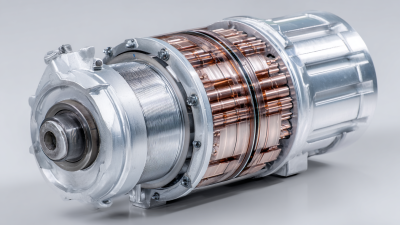

Permanent Magnet (PM) synchronous motors have gained significant attention due to their exceptional efficiency compared to traditional induction motors. The energy efficiency of PM motors stems from their design; they use permanent magnets to create a magnetic field, which significantly minimizes energy losses. In contrast, induction motors rely on electromagnetic induction, which can lead to energy loss and lower overall efficiency. This comparative analysis reveals that PM synchronous motors not only improve operational efficiency but also provide better performance control in various applications.

When considering the transition to PM motors, industry players should weigh several factors.

Tip 1: Assess the specific application requirements; for high-performance applications with precise control, PM motors might be the best fit.

AC microgrid systems, while widely used, can sometimes struggle with efficiency in certain contexts. Exploring DC microgrid systems presents an innovative solution that can reduce energy loss and increase overall system efficiency. By focusing on the comparative benefits of PM synchronous motors and DC microgrids, industries can unlock new opportunities for innovation and sustainability.

Tip 2: Always conduct a thorough cost-benefit analysis to understand the long-term savings and potential return on investment of upgrading to PM motors or implementing DC microgrids.

The future of Permanent Magnet (PM) synchronous motors is poised for significant transformation, driven by rapid technological innovations and expanding applications.

As industries continue to prioritize energy efficiency and sustainability, the design of PM synchronous motors is being optimized to meet these demands. The growing interest in electric vehicles and renewable energy sources is propelling advancements in motor technology, leading to enhanced performance and reduced environmental impact.

In parallel, the global market for motor laminations is experiencing noteworthy growth, projected to rise from USD 21.38 billion in 2025 to USD 30.89 billion by 2030. This surge indicates a broader trend towards integrated electro-industrial systems, where hardware increasingly converges with software solutions.

As this industry evolves, the emergence of intelligent control systems and IoT-enabled devices will play a crucial role in enhancing the efficiency and versatility of PM synchronous motors, positioning them as key players in the next industrial revolution.