Centrifugal Cast Roll Sleeve – High-Performance Wear-Resistant Component for Industrial Machinery

-

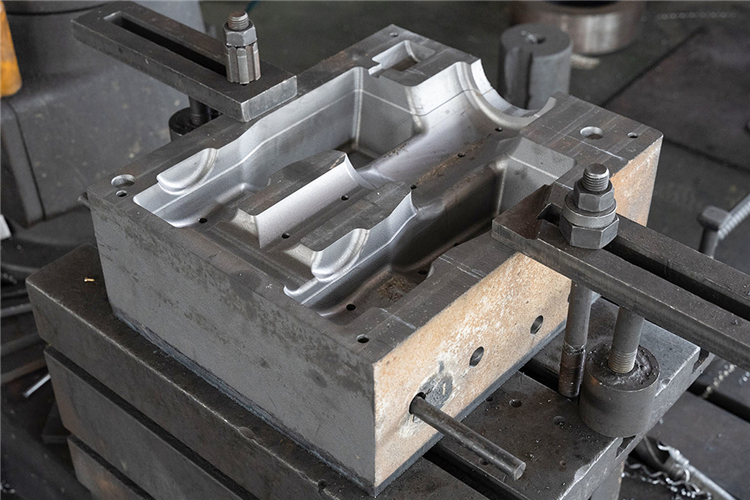

Material Advantages

- 35CrMnSi: This alloy steel balances strength and toughness perfectly. With excellent hardenability, the roll sleeve retains high hardness and wear resistance post-heat treatment, ensuring prolonged service.

- 35CrNiMo: Praised for its superior mechanical properties, it boosts the sleeve’s impact and fatigue resistance, enabling stable operation under extreme loads.

- Wear-Resistant Alloy Steel & Hard Alloy: The combination forms a robust anti-wear layer. Hard alloy particles embedded in the alloy steel matrix combat material abrasion, reducing wear and extending lifespan.

-

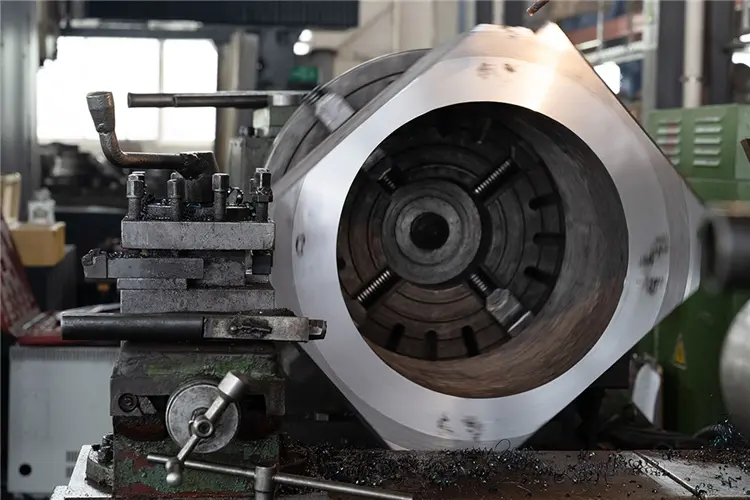

Process Excellence

- Centrifugal casting ensures a dense structure and uniform material distribution, minimizing defects like pores. This guarantees consistent quality, high strength, and reliable performance.

-

Wide Applications

Ideal for:

- Metallurgy: Equipment processing sintered ore and pellets.

- Mining: Ore-crushing and grinding machinery.

- Building Materials: Machinery handling cement clinker, limestone.

- Power Generation: Coal and slag processing equipment.

-

After-Sales Support

- We offer professional technical guidance, timely spare parts, and customized solutions. Our aim: ensure your satisfaction and optimize equipment efficiency.

- Opt for our centrifugal cast roll sleeve—where top-tier materials, advanced craftsmanship, and reliable performance enhance machinery durability. Elevate your operations today!

Technical Parameters

| Parameter | Details |

| Material | 35CrMnSi, 35CrNiMo, wear-resistant alloy steel, hard alloy |

| Hardness | [e.g., HRC 55–62] |

| Impact Toughness | [e.g., 12–18 J/cm²] |

| Service Temperature | [e.g., ≤300℃] |