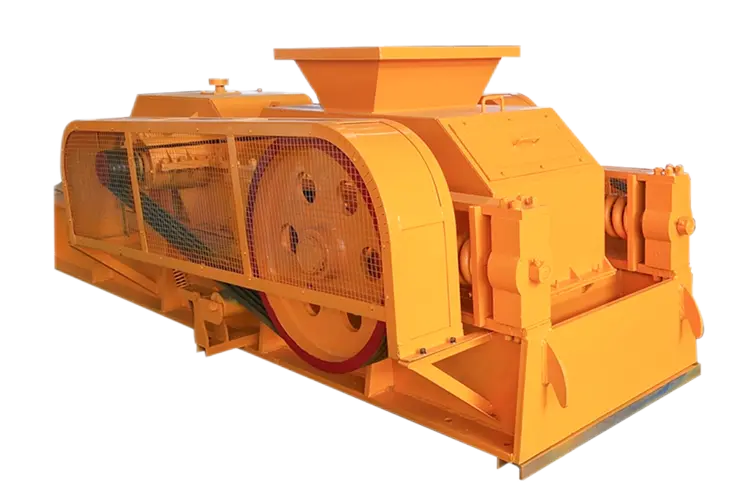

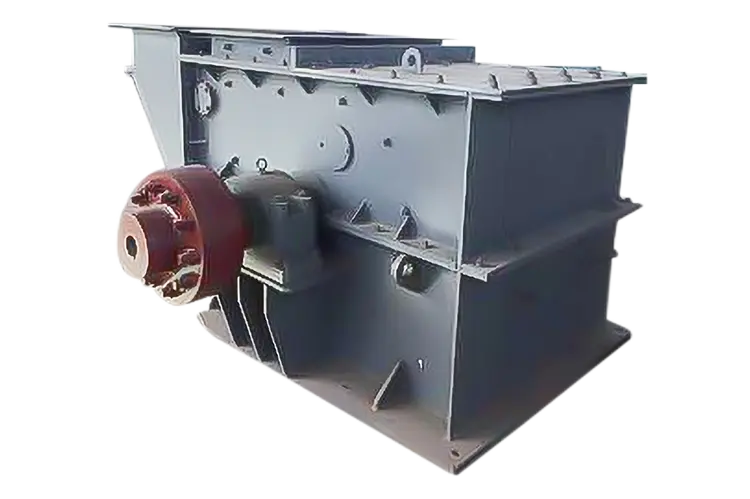

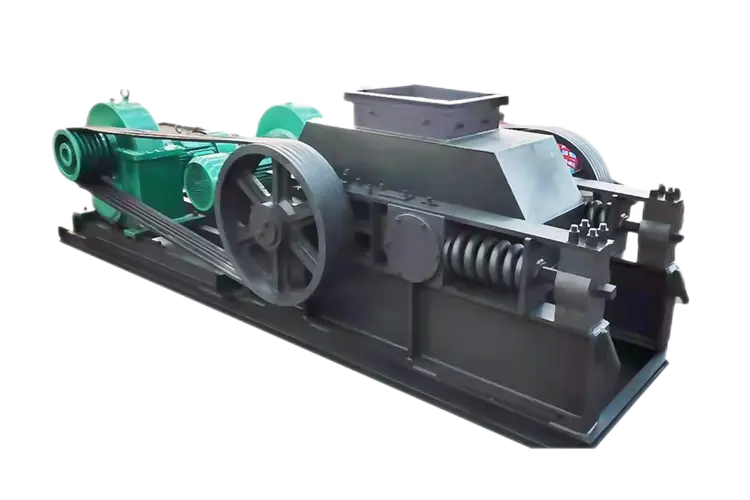

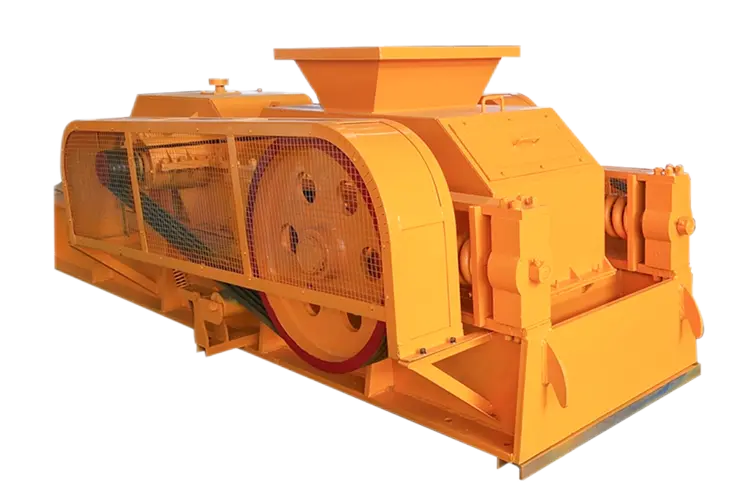

Double Roll Crusher – Efficient Crushing Solution for Medium-Hard Materials

-

Working Principle

-

Materials fall into the gap between two rotating rolls from the feeding port. Through extrusion, the materials are crushed, and the finished products naturally drop. When encountering overly hard or uncrushable materials, the rolls automatically yield via hydraulic cylinders or springs, increasing the gap to let the materials pass—protecting the machine from damage. By adjusting the gap between the two oppositely rotating rolls, you can precisely control the discharge particle size.

-

-

Main Features

- 1.Easy Discharge Adjustment: A wedge device with adjustment bolts allows quick control over the roll gap. Raising the wedge increases the gap for larger particle discharge; lowering it reduces the gap for finer particles.

- 2.Stable Drive System: Driven by two electric motors, a three-angle belt transmits power to the rolls, ensuring opposite-direction rotation. Materials enter from the feed port, are crushed by the rolls, and exit from the bottom.

- 3.Durable & Safe Design: The transmission part uses high-quality wear-resistant materials (especially the grinding rolls, which are reusable), extending service life. Safety covers can be installed per user needs, reducing failure rates.

- 4.Energy-Efficient & High-Quality Output: By lowering feed particle size and improving material quality, it achieves multi-crushing and grinding, optimizing product shape, enhancing crushing capacity, and delivering high output with low energy consumption.

-

Applications

- Coal Mining: Crushing coal and associated minerals.

- Cement Industry: Processing raw materials for cement production.

- Metallurgy & Chemical Sectors: Mid-crushing and fine-crushing of ores and chemical raw materials.

- Building Materials: Producing aggregates for construction projects.

-

Take Action

- Ready to upgrade your crushing efficiency?

- Get a Custom Quote—Tailored solutions for your material processing requirements.

- Download Product Brochure—Explore more details about our Double Roll Crusher.

- Contact Our Experts—Let us support your project planning, technical inquiries, and equipment selection.

- Choose our Double Roll Crusher for reliable performance, precise control, and long-term value in your material processing operations!

Technical Parameters

| Model | 2PG0425 | 2PG0640 | 2PG0740 | 2PG0850 | 2PG1060 | 2PG1260 | 2PG1560 |

| Roll Diameter (mm) | Φ400 | Φ600 | Φ700 | Φ800 | Φ1000 | Φ1200 | Φ1500 |

| Roll Width (mm) | 250 | 400 | 400 | 500 | 600 | 600 | 600 |

| Feed Size (mm) | ≤25 | ≤25 | ≤25 | ≤25 | ≤30 | ≤30 | ≤30 |

| Discharge Size (mm) | 2–8 | 2–8 | 2–8 | 2–8 | 2–10 | 2–10 | 2–10 |

| Processing Capacity (t/h) | 3–10 | 5–20 | 10–30 | 15–40 | 20–50 | 25–70 | 30–110 |

| Motor Model | Y132M-6 | Y180L-6 | Y200L-4 | Y225M-4 | Y250M-4 | Y315M-6 | Y315L-6 |