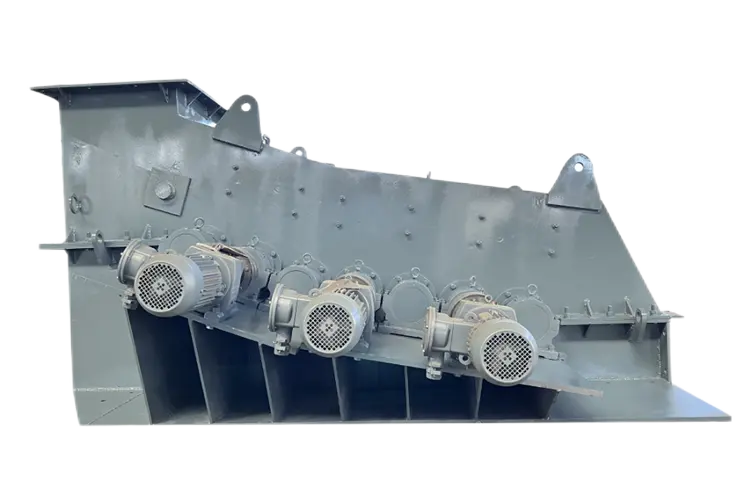

Innovative Screening & Crushing Machine – All-in-One Solution by Sorun

-

Working Principle

-

Raw materials enter the machine’s screening section—cross screen—via the conveyor pipe. Qualified fine powder (meeting particle size requirements) falls under the “flutter” effect of CRS cross screen pieces. Remaining materials roll and disperse on the screen; evenly dispersed materials then enter the PCH crusher. The crusher’s large crushing cavity ensures robust crushing power.

-

-

Main Features

- 1.Space Efficiency: Compact system layout eliminates the need for a separate screening layer.

- 2.Versatile Adaptability: Suits various coal types (raw coal, medium coal, inferior coal) with no strict moisture requirements. Excels in high-moisture, high-adhesion coal, or materials with abundant fines.

- 3.High-Efficiency Design: Adopts the “large screening, small crushing” concept. With over 90% screening efficiency, it minimizes over-crushing and reduces crusher load.

- 4.Superior Crushing Structure: Features an advanced crushing cavity with a large hammerhead. The crusher’s bottom (without a screen plate) ensures discharge particle size meets demands.

-

Why Choose Our Machine?

- Cost Savings: Reduces construction expenses via optimized layout.

- Efficiency Boost: Integrates screening and crushing for streamlined processing.

- Reliable Operation: Performs stably even with challenging materials like high-moisture coal.

- Efficiency Boost: Integrates screening and crushing for streamlined processing.

-

Take Action

- Ready to elevate your production?

- Request a Custom Quote – Tailored solutions for your material processing.

- Download Product Catalog – Dive deeper into our Screening and Crushing Machine.

- Contact Our Experts – Let us support your project planning and technical needs.

- Trust Sorun Group’s Screening and Crushing Machine to deliver innovation, efficiency, and cost-effectiveness for your industrial operations!

Technical Parameters

| Specification | Input Size (mm) | Discharge Size (mm) | Processing Capacity (t/h) | Motor Power (KW) |

| SYPSYT0808 | 200 | 30 | 80–200 | 45 + 5×1.5 |

| SYPSYT1010 | 300 | 30 | 200–400 | 90 + 6×2.2 |

| SYPSYT1012 | 300 | 30 | 400–600 | 110 + 6×2.2 |

| SYPSYT1016 | 400 | 30 | 600–800 | 160 + 8×2.2 |

| SYPSYT1216 | 400 | 30 | 800–1000 | 220 + 8×2.2 |

| SYPSYT1218 | 400 | 30 | 1000–1500 | 315 + 8×2.2 |