Company News

News Categories

Featured News

vacuum pumps

2025-10-16

IntroductionIn the field of industrial production, vacuum pumps are key equipment, and their performance directly affects many important aspects such as production efficiency, energy consumption levels, and product quality. Due to the differences in process characteristics and requirements in different industries, there are unique considerations for the selection and application of vacuum pumps. The magnetic levitation vacuum pumps produced by Shandong Shuoyuan Power Technology Co., Ltd. have the advantages of high efficiency and energy saving, low maintenance costs, stable and reliable operation, and significant performance advantages. The following will deeply analyze the application of vacuum pumps in actual production, the problems faced, and the remarkable results after technological transformation through two typical cases.

Case 1: Wuxiang Branch of Beijing Qingxin Environment Technology Co., Ltd.The Wuxiang Branch of Beijing Qingxin Environment Technology Co., Ltd. is located in the Xishan Coal and Electricity Power Plant in Wuxiang County, Changzhi City, Shanxi Province. The Wuxiang Power Plant is equipped with 2 units with a total installed capacity of 2×600MW, both of which are sub - critical coal - fired units. The desulfurization systems of the two units both adopt the limestone - gypsum wet flue gas desulfurization technology. The by - product of the desulfurization system of this power plant is calcium sulfate dihydrate. In the gypsum slurry treatment process, the vacuum belt dewatering method is used. The gypsum slurry (with a solid content of about 40 - 60wt%) concentrated by the gypsum cyclone flows automatically to the belt dewatering machine for dewatering operation, with the goal of further dewatering to gypsum with a solid content of not less than 90% wt (moisture content of not more than 10% wt), and it is planned according to the comprehensive utilization direction.The original desulfurization system was equipped with 3 vacuum belt dewatering machines, and each dewatering belt machine was equipped with 1 water - ring vacuum pump. However, the water - ring vacuum pump has exposed many problems in actual operation. Its operation efficiency is low, the energy consumption is high, the noise generated during operation is large, and it needs frequent maintenance. This not only increases the operation cost but also has a certain impact on the stability of production.In view of the disadvantages of the water - ring vacuum pump, Shandong Shuoyuan Power Technology Co., Ltd. replaced it with a magnetic levitation high - speed centrifugal vacuum pump. The magnetic levitation high - speed centrifugal vacuum pump uses the high - speed permanent - magnet motor direct - drive technology to achieve completely contact - free and friction - free operation. This characteristic makes the equipment noise greatly reduced, the maintenance amount significantly decreased, and the energy - saving effect is very obvious.The following is a comparison of the basic parameters of the vacuum pumps:

| Model | Vacuum Degree (-KPa) | Maximum Gas Extraction Volume (m³/min) | Motor Power (KW) |

|---|---|---|---|

| SRV185 (Magnetic Levitation High - Speed Centrifugal Vacuum Pump) | -40 | 210 | 185 |

| Original Water - Ring Vacuum Pump | -40 | 206 | 280 |

| From the energy - saving comparison data: | |||

| Equipment Name | 280kw Water - Ring Vacuum Pump | Magnetic Levitation Vacuum Pump | |

| -- | -- | -- | |

| Model | 2BE3500 - 2BY4 | SRV185 | |

| Rated Power | 280kw | 185kw | |

| Vacuum Degree | -40kPa | -40kPa | |

| Maximum Pumping Speed | 206m³/min | 210m³/min | |

| Operating Total Power | 260kw | 175kw (under the same working conditions) | |

| Power Saving | About 85kW | - | |

| Number of Operating Units | 1 | - | |

| Energy - Saving Rate | >25% (about 32.7%) | - | |

| Energy Consumption Saved | 8000×85 = 680,000 kWh per year according to 8000 hours of operation | - | |

| Power - Saving Cost | The power - saving cost is 216,000 yuan calculated at the electricity price of 0.317 yuan/kwh | - |

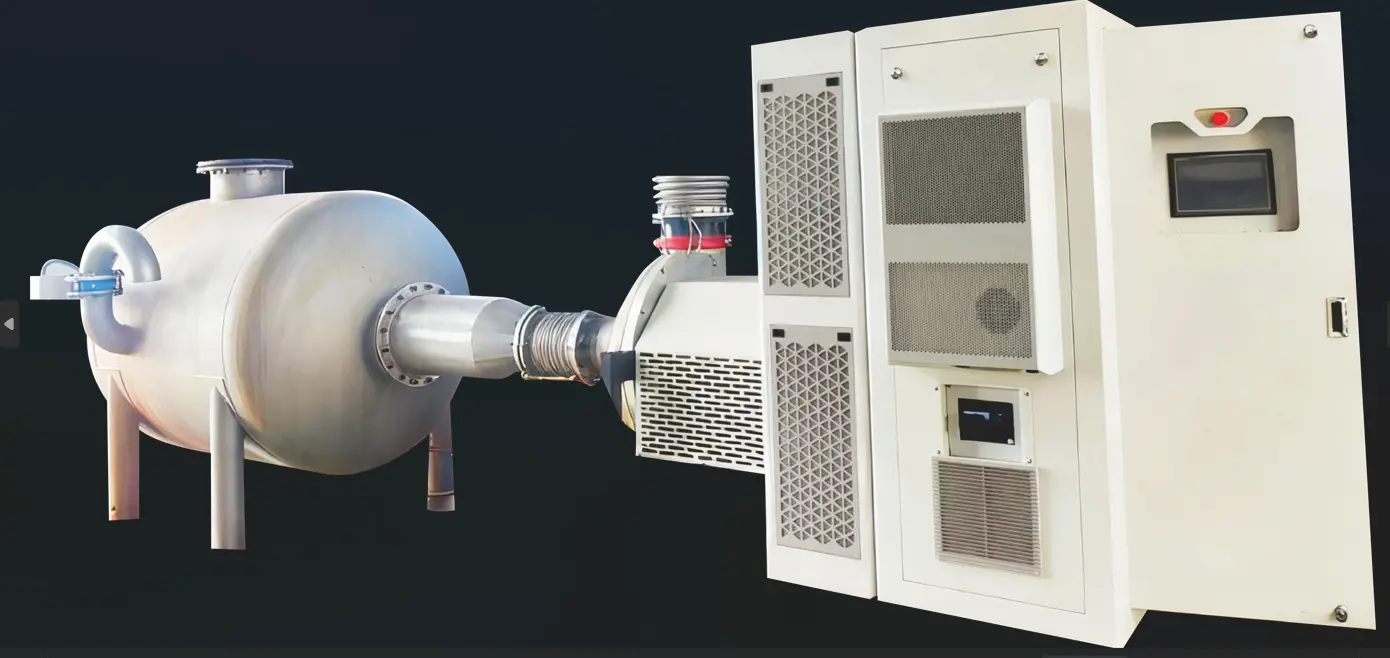

Case 2: State Power Investment Group Shanxi Aluminum Co., Ltd.The roasting workshop of State Power Investment Group Shanxi Aluminum Co., Ltd. has 2 flat - disc filters, each equipped with 2 water - ring vacuum pumps. The vacuum pumps are produced by Zibo Water - Ring Vacuum Pump Factory Co., Ltd., and the model is 2BEC67. Its maximum pumping speed is 375m³/min, the ultimate vacuum is 160hPa, and it is equipped with a YKK450 - 4 asynchronous motor and an IC355N SEW reducer.In the actual operation process, the vacuum pump also has a series of problems. The operation efficiency is low, and the scaling speed is fast, resulting in a significant decline in equipment performance. Due to the high operation rate of the equipment, once a failure occurs or maintenance is required, it will have an adverse impact on production and index control.To solve these problems, it is planned to replace one of the existing water - ring vacuum pumps with a magnetic levitation turbo - vacuum pump and install a horizontal steam - water separator. After the transformation by Shandong Shuoyuan Power Technology Co., Ltd., the single - unit operating power is reduced from 375Kw to below 255Kw; the maximum gas extraction volume is increased from 375m³/min to above 400m³/min; the vacuum degree is increased to about - 50kpa. Moreover, when the magnetic levitation turbo - vacuum pump is working, there is no friction between the rotating part and other parts, and no lubrication treatment is required. It is free from mechanical maintenance for life, and only the filter cotton and separator filter element need to be cleaned regularly, which will effectively reduce the maintenance cost and labor.The following is a comparison of the equipment parameters before and after the transformation:

| Name | Specification Model | Quantity | Power | Voltage | Vacuum Degree | Rated Gas Extraction Volume | Remarks |

|---|---|---|---|---|---|---|---|

| Original Water - Ring Vacuum Pump | 2BEC67 | 1 unit | 375KW | 10KV | 160hPa | 375m³/min | - |

| Magnetic Levitation Turbo - Vacuum Pump | TRV400 | 1 unit | 400KW | 10KV | -47KPa | 400m³/min |